Multipart packing ring

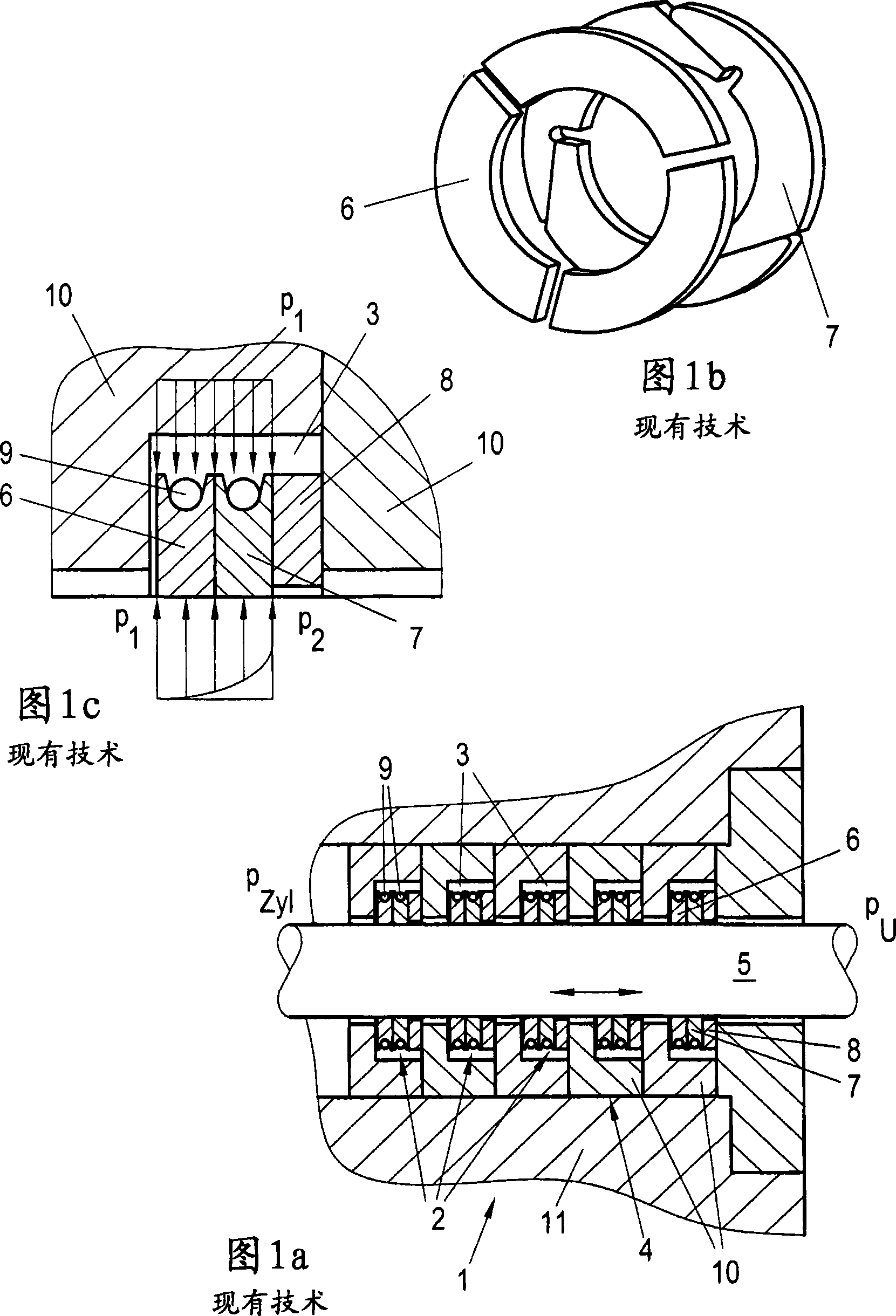

A sealing ring and multi-body technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of uneven wear rate, reduce the pressure per unit area of the sealing surface, and large leakage of the sealing ring, so as to achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

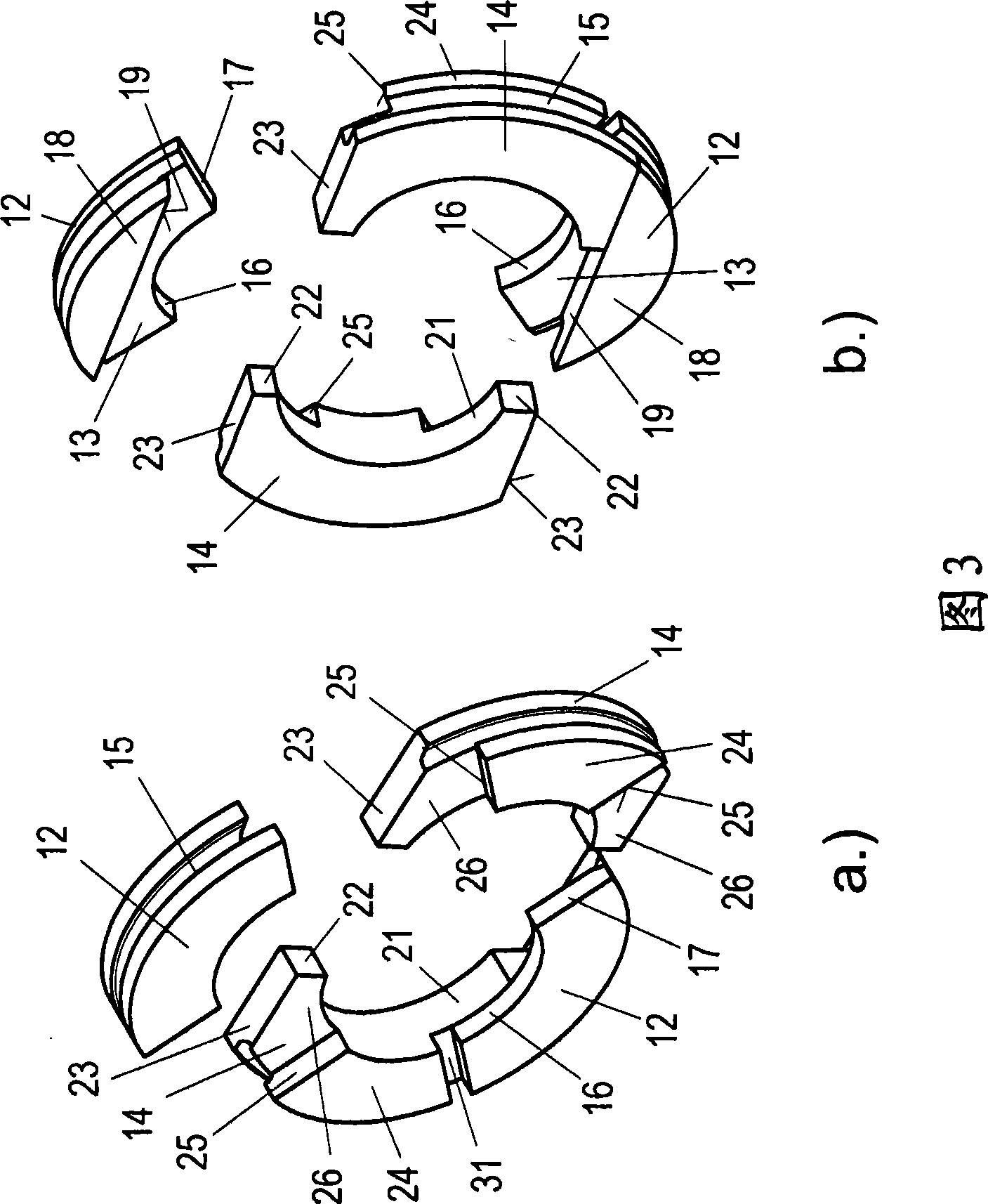

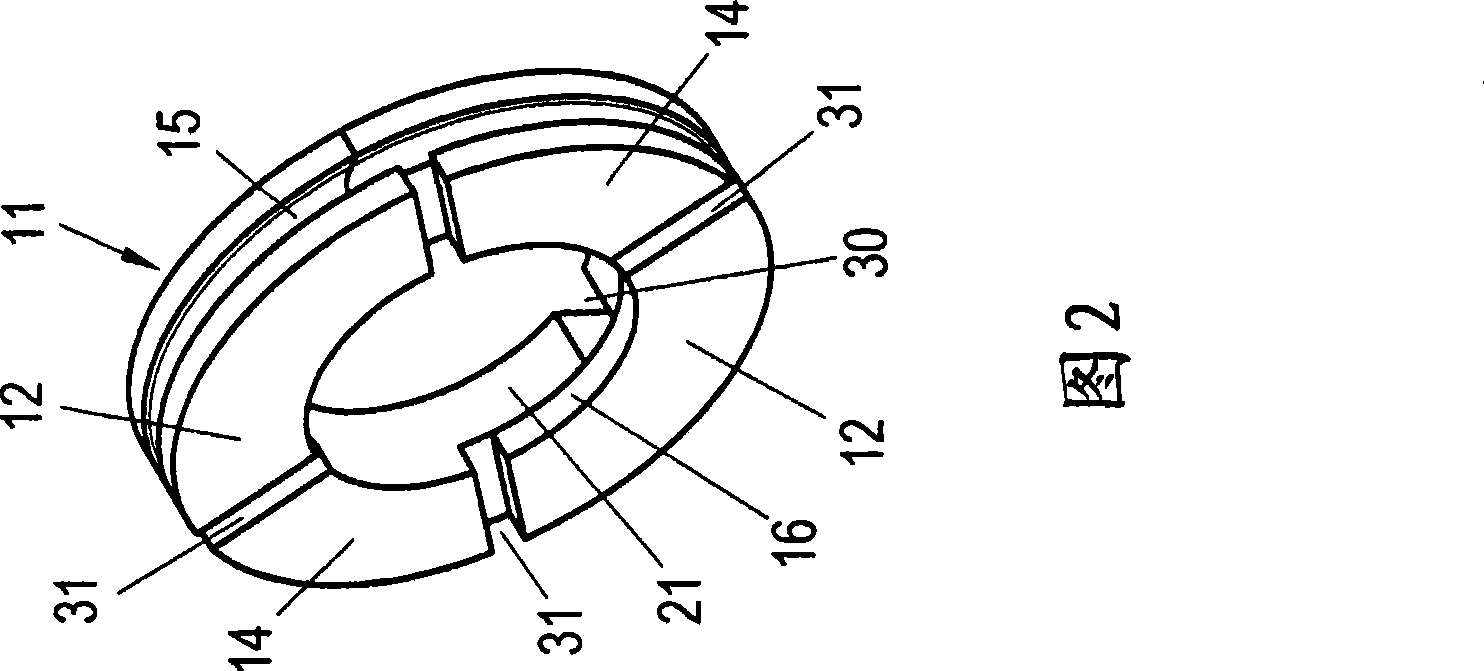

[0024]A preferred embodiment of the multi-part sealing ring 11 is shown in FIG. 2 in the form of a four-part ring. The same sealing ring is shown in different views of the exploded view in FIGS. 3 a and 3 b for a better understanding. The following description refers to FIGS. 2 and 3 .

[0025] The sealing ring 11 here consists of four parts, namely two segment segments 12 and two sealing segments 14 , which form a ring and abut one another tightly. An annular groove 15 may be formed in the outer circumference of the arcuate and sealing segments 12, 14, in which an annular spring may be arranged to hold the segments together. The two arcuate sections 12 and the sealing section 14 are arranged opposite to each other.

[0026] The segment 12 radially has a curved, generally circular peripheral surface 16 which, during use of the sealing ring 11, rests tightly against the component to be sealed, in this case the piston of the compressor. on the pole. An axially protruding sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com