Axial rolling bearing for a suspension

A technology of thrust bearings and suspensions, applied in the direction of suspensions, ball bearings, elastic suspensions, etc., can solve the problems of high cost, inability to fully and effectively ensure sealing, high rigidity, etc., and achieve low quality and good storage and conveying, highly compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

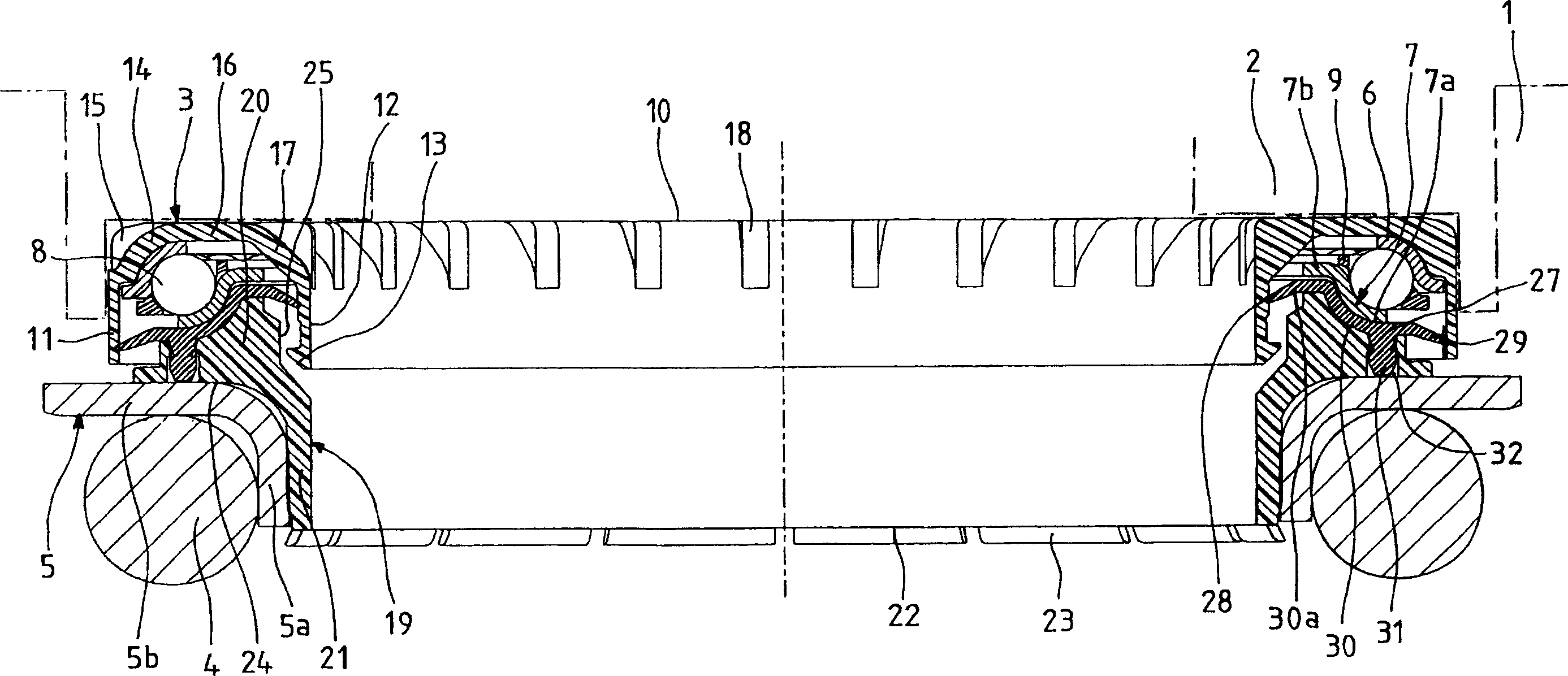

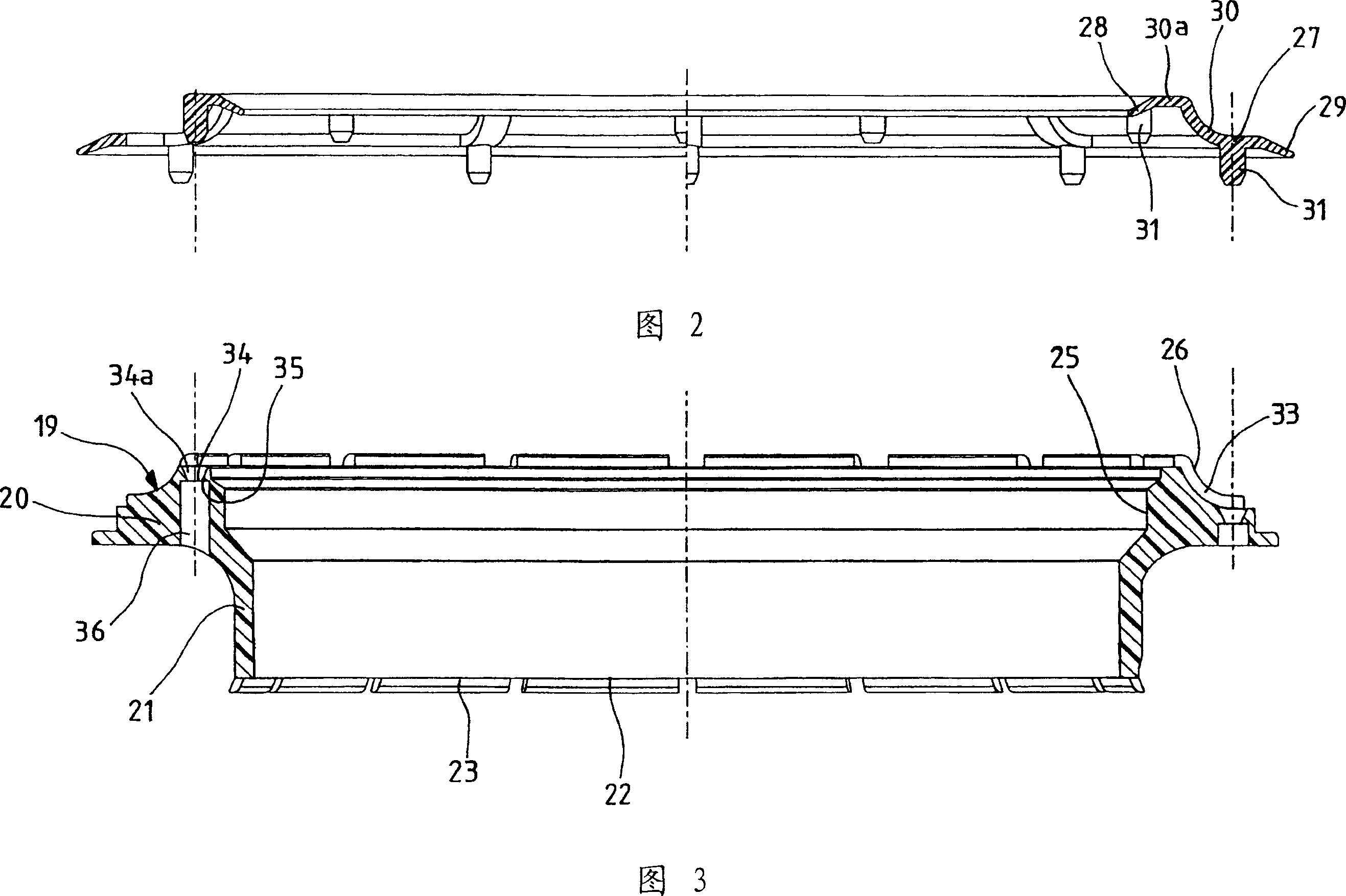

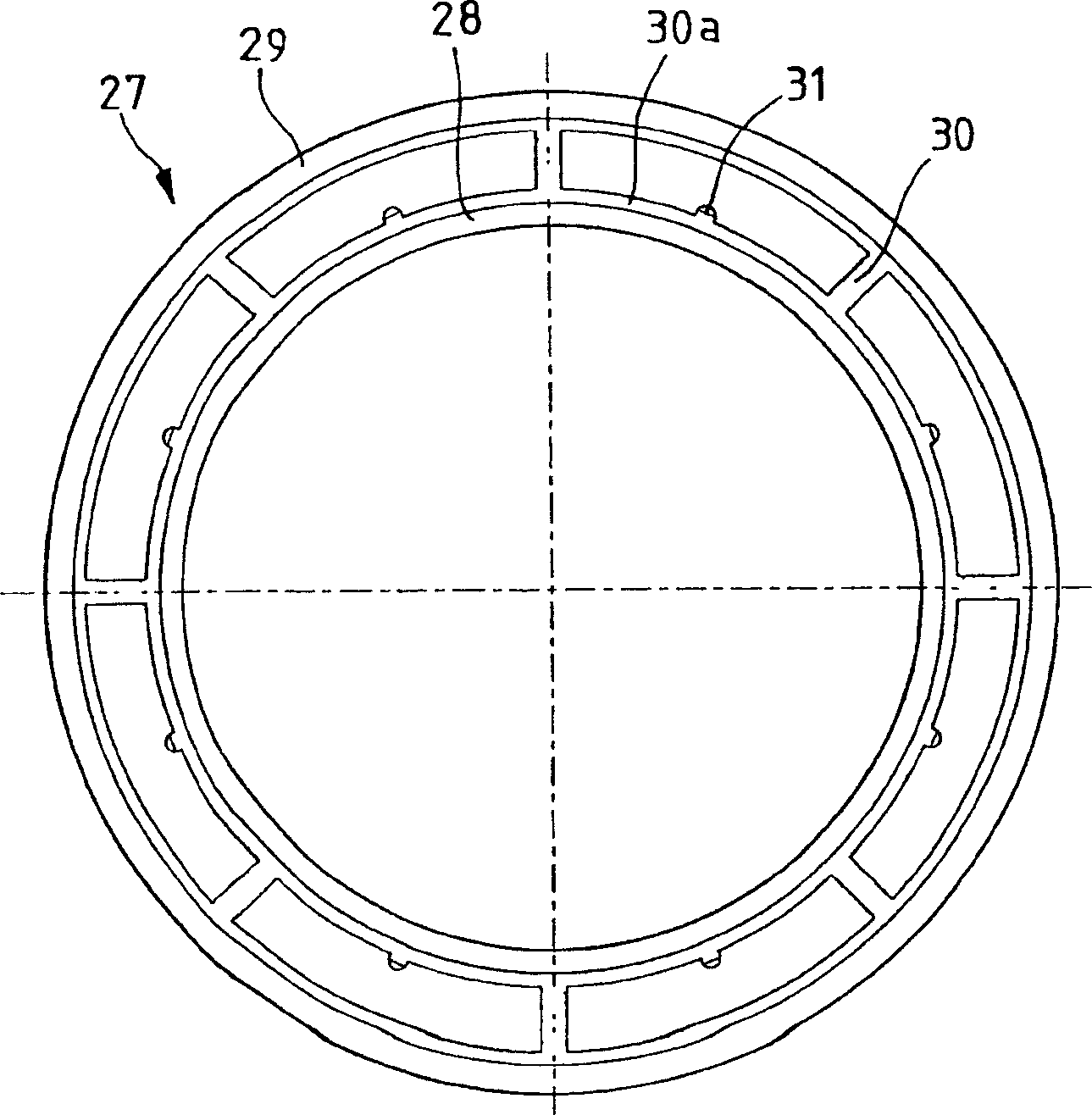

[0043] A shock absorber comprises a cylinder in which a piston can slide, the piston rod being connected by its upper end to an elastic support block 1 supported on and connected to a chassis member constituting a base.

[0044] The elastic support block 1 includes an upper disk 2 and a rubber block. The upper disk 2 is used as a support for the thrust bearing 3. The rubber block is bonded to the surfaces of these three components, and the vibration filter between them is realized. Connection.

[0045] A suspension spring 4 is pressed against a lower disc 5 which is pressed against the thrust bearing 3 .

[0046] The upper disc 2 comprises a downwardly extending cylindrical portion 2a on the opposite side of the base frame and an outwardly extending radial portion 2b. The inner surface of the cylindrical portion 2a and the upper surface of the radial portion 2b are covered with the elastic material used in the elastic support block 1 .

[0047] Obviously, this support supers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com