Preparation method and equipment capable of improving manufacturing qualification rate of claws and connecting rods

A pass rate and connecting rod technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult oxyacetylene surfacing, low final pass rate of surfacing layer, narrow control range of surfacing layer hardness, etc. , to achieve the effect of benefiting the quality of the surfacing layer and reducing internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

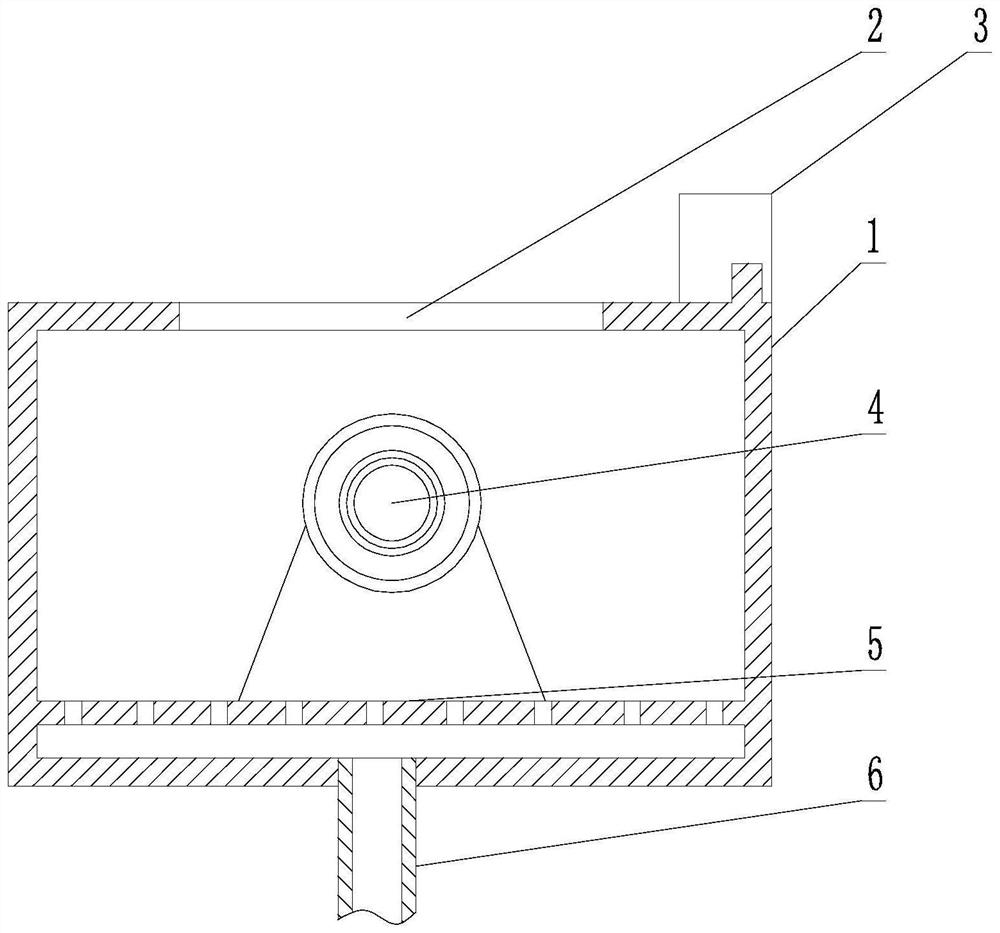

[0066] Such as image 3 Shown, a kind of preparation equipment that can improve hook claw, connecting rod manufacturing pass rate, described preparation equipment comprises the surfacing box 1 that is box structure, and the top of described surfacing box 1 is also provided with as surfacing box 1 open opening 2;

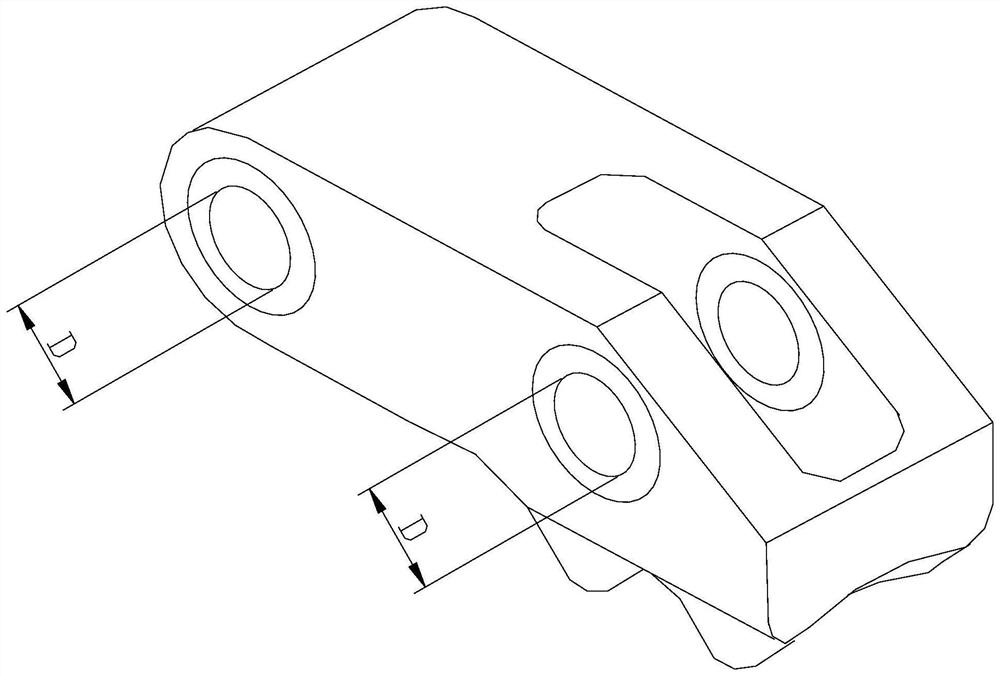

[0067] It also includes a mounting frame 4 arranged in the surfacing box 1, the mounting frame 4 is provided with an installation station for installing the filling rod, and at the installation station, the filling rod can rotate around its own axis;

[0068] The opening 2 is used as an operation channel for welding the surfacing layer on the filler rod;

[0069] It also includes a gas source pipe 6 whose outlet end is located in the surfacing box 1 .

[0070] In the prior art, for the preparation of claws and connecting rods, a common method is to obtain a wear-resistant layer on the base material by surfacing welding. Selection of the base material: the material...

Embodiment 2

[0077] This embodiment is further limited on the basis of Embodiment 1. Since the required filling mandrel is strip-shaped, in order to make the shape of the surfacing box 1 and the opening 2 more suitable for installation as a filling rod, it is convenient to pass the surfacing gun along the filling rod. The axis moves to obtain a surfacing layer extending along the axial direction of the filling rod, which is set as follows: the surfacing box 1 is strip-shaped, the opening 2 is arranged on the top plate of the surfacing box 1, and the opening 2 is a length The extension direction is along the strip shape along the length direction of the overlay welding box 1 .

[0078] In order to realize such as automatic surfacing torch movement and specific wire feeding position matching adjustment, it is set as follows: it also includes a walking trolley 3 that can reciprocate along the length direction of the opening 2, and the walking trolley 3 is provided with an The fixed position o...

Embodiment 3

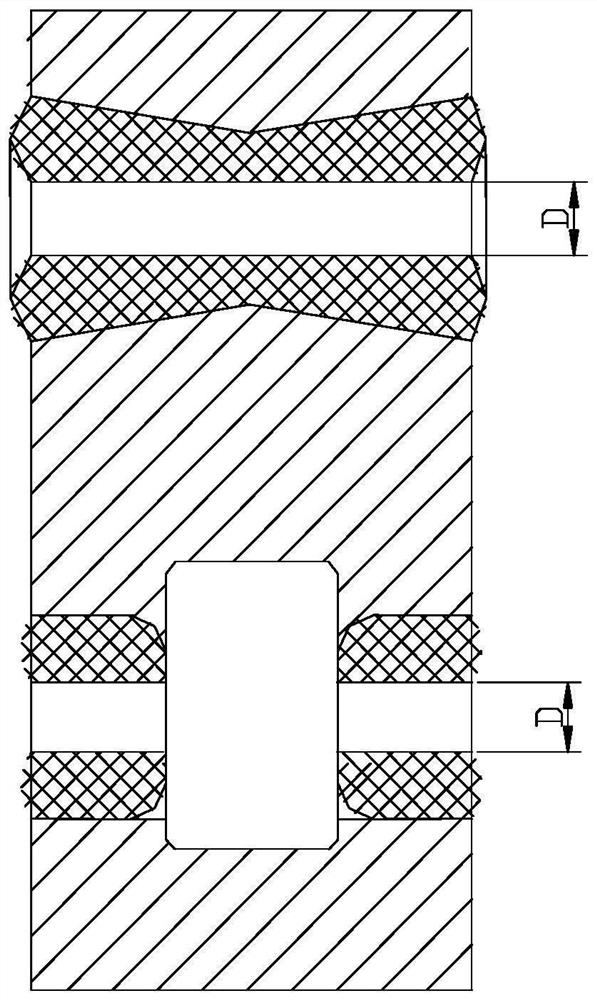

[0086] This embodiment is further limited on the basis of Example 1. This embodiment also discloses a preparation method that can improve the production yield of hooks and connecting rods. The preparation method is as follows: Drill a prefabricated hole on the part, then weld the filling mandrel in the prefabricated hole, and then carry out hole processing on the filling mandrel to obtain a wear-resistant layer of the hole wall on the part, and the filling mandrel adopts any one of the above provided The manufacturing equipment is based on the filling rod as the filling mandrel matrix, and the filling mandrel is obtained by surfacing the surfacing layer for the oxyacetylene flame of the carbonization flame, and the specific method is as follows:

[0087] Install the filling rod on the installation frame 4, and inject anti-oxidation protective gas into the surfacing box 1 through the gas source pipe 6;

[0088] Using the opening 2 as a surfacing operation channel, the surfacing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com