Environment-friendly steel lattice plate manhole cover

A type of steel and grating technology, which is applied in the field of environmentally friendly steel grating manhole covers, can solve the problems of unfavorable drainage and easy entry of garbage and other sundries, and achieve the effects of simple structure, convenient installation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

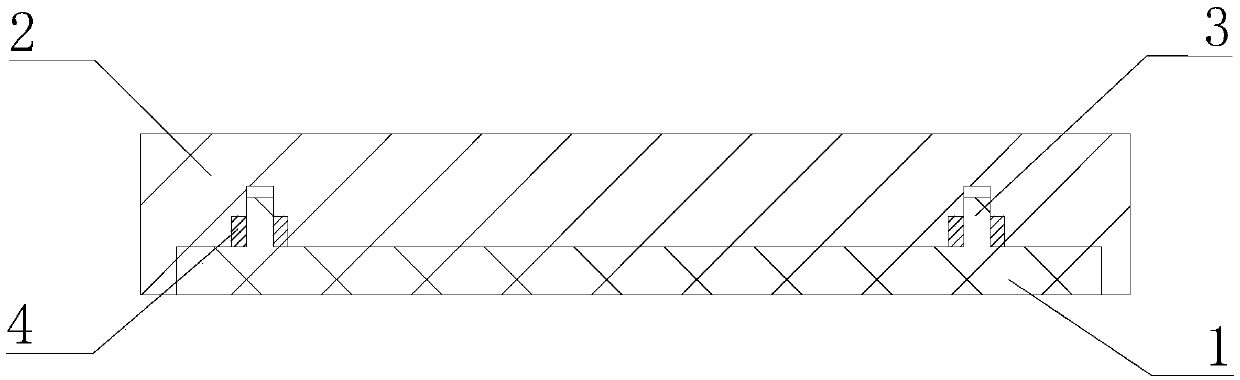

[0010] refer to figure 1 , an environment-friendly steel grating manhole cover proposed by the present invention includes a steel grating and a filter assembly, the filter assembly includes a filter screen and a filter screen frame 1, the filter screen is installed in the filter screen frame 1, and the filter screen frame 1 is provided with at least two There are two installation columns 3 distributed along the circumferential direction. The steel grating includes a frame body 2 and flat steel bars and cross bars arranged in the frame body 1. The stepped groove for accommodating the filter screen skeleton 1, the inner bottom wall of the stepped groove is provided with a step hole, the thick end of the step hole is provided with an elastic ring body 4, and one end of the elastic ring body 4 is fixedly connected with the step of the step hole, and the step hole Corresponding to the installation column 3 one by one, the installation column 3 extends from the thick end of the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com