Method for removing phosgene from isophthalylidene diisocyanate

A technology of iso-xylylene diisocyanate and phosgene, which is applied in the field of phosgene removal of iso-xylylene diisocyanate, can solve problems such as difficult removal of phosgene, improve safety and reduce load , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

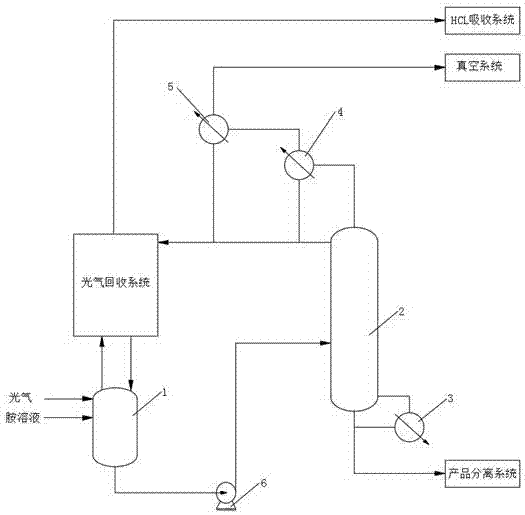

Image

Examples

Embodiment 1

[0023] A mixed solution of amine and o-dichlorobenzene with a concentration of 4.8% and a flow rate of 1000kg / h, and phosgene at a temperature of -10°C and a flow rate of 278kg / h are subjected to a cold and hot photochemical reaction in the photochemical reactor 1. The HCL gas and excess phosgene generated after photochemistry are passed into the phosgene recovery system; the reacted photochemical liquid contains XDI, o-dichlorobenzene, phosgene and HCL, the temperature is 138°C, and the flow rate is 1481kg / h. The phosgene content is 2.5%, and the isocyanate content is 4.0%. The phosgene removal tower 2 is continuously fed into the phosgene removal tower 2 by the photochemical liquid discharge pump 6 for rectification. The operating pressure of the phosgene removal tower 2 is -0.2 barg; In addition to the mixed gas such as solvent and phosgene coming out of the top of the tower 2, it enters the first stage condenser 4 at the top of the tower, and its temperature is controlled a...

Embodiment 2

[0025] A mixed solution of amine and o-dichlorobenzene with a concentration of 4.8% and a flow rate of 1000kg / h, and phosgene at a temperature of -10°C and a flow rate of 278kg / h are subjected to a cold and hot photochemical reaction in the photochemical reactor 1. The HCL gas and excess phosgene generated after photochemistry are passed into the phosgene recovery system; the reacted photochemical liquid contains XDI, o-dichlorobenzene, phosgene and HCL, the temperature is 138°C, and the flow rate is 1481kg / h. The phosgene content is 2.5%, and the isocyanate content is 4.0%. The phosgene removal tower 2 is continuously fed into the phosgene removal tower 2 by the photochemical liquid discharge pump 6 for rectification. The operating pressure of the phosgene removal tower 2 is -0.1 barg; In addition to the mixed gas such as solvent and phosgene coming out of the top of tower 2, it enters the first stage condenser 4 at the top of the tower, and its temperature is controlled at 30...

Embodiment 3

[0027]A mixed solution of amine and o-dichlorobenzene with a concentration of 4.8% and a flow rate of 1000kg / h, and phosgene at a temperature of -10°C and a flow rate of 278kg / h are subjected to a cold and hot photochemical reaction in the photochemical reactor 1. The HCL gas and excess phosgene generated after photochemical pass into the phosgene recovery system; the reacted photochemical liquid contains XDI, o-dichlorobenzene, phosgene and HCL, its temperature is 139°C, and its flow rate is 1481kg / h. The phosgene content is 2.5%, and the isocyanate content is 4.0%. The phosgene removal tower 2 is continuously fed into the phosgene removal tower 2 by the photochemical liquid discharge pump 6 for rectification. The operating pressure of the phosgene removal tower 2 is -0.5 barg; In addition to the mixed gas such as solvent and phosgene coming out of the top of tower 2, it enters the first stage condenser 4 at the top of the tower, and its temperature is controlled at 50°C; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com