Heat-dissipation split-type conjunction box used for solar assembly and solar cell assembly thereof

A split junction box and solar module technology, which is applied in the field of solar modules, can solve problems such as complex production process, long connecting cables, unfavorable heat dissipation, etc., and achieve the effects of heat dispersion, volume reduction, and improvement of production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

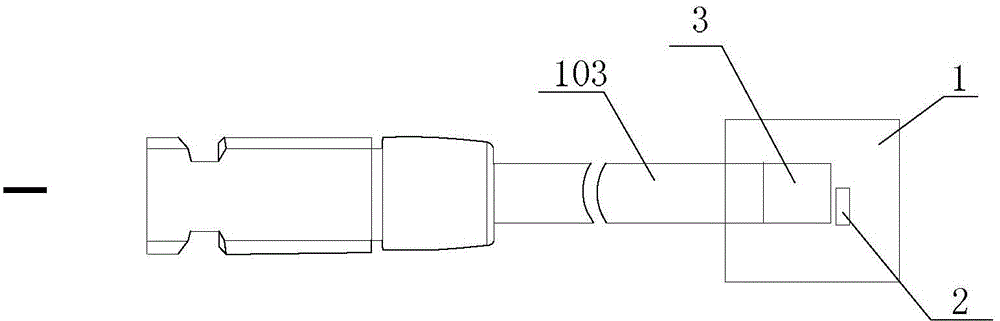

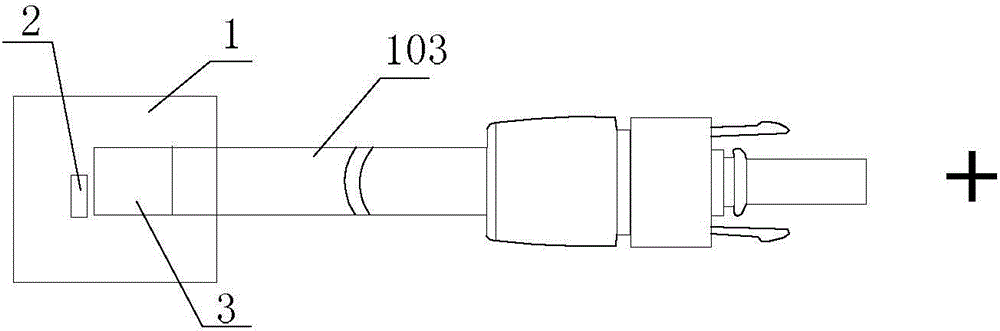

[0032] Such as Figure 1-3 As shown, the heat-dissipating split junction box for solar modules of the present invention includes a negative terminal box 10, an intermediate terminal box 20, and a positive terminal box 30 that are independent of each other, and the intermediate terminal box 20 is arranged between the negative terminal box 10 and the positive terminal box. Between the boxes 30, the negative wire box 10 is connected to the negative pole of the photovoltaic connector, and the positive wire box 30 is connected to the positive pole of the photovoltaic connector. Each wire box includes a box body 1 and a box cover that can close the box body. At the starting end of the negative electrode of the module, there is only one terminal 3 for connecting the lead wire 2 of the module, and the terminal 3 is connected to the negative terminal of the photovoltaic connector through the cable 103 at the same time; the positive terminal box 30 is arranged on the solar cell module A...

Embodiment 2

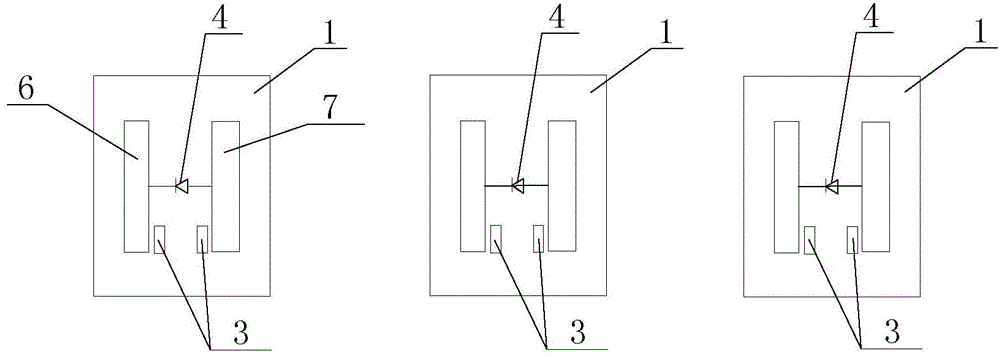

[0035] Such as Figure 4-6 As shown, the difference between this embodiment and Embodiment 1 is that the bypass diode 4 is located on one side of the terminal 3. For the convenience of description, the two conductors are named as the first conductor 6 and the second conductor 6 here. Conductor 7, the two ends of the first conductor 6 are bent to form two first connecting parts 6a parallel to the second conductor 7, and a transverse direction is formed between the two first connecting parts 6a and the second conductor 7 Two connection bits 5 are distributed, so that the bypass diode 4 and the terminal post 3 are horizontally arranged side by side. The second conductor 7 is located between the two first connection portions 6 a of the first conductor, and two second connection portions 7 a connected to the first connection portions 6 a are formed on the second conductor 7 .

[0036] In this embodiment, the arrangement of the bypass diodes and the binding posts connected to the lea...

Embodiment 3

[0038] Such as Figure 7 As shown, another aspect of the present invention provides a solar cell module 100 using the heat dissipation type split junction box for the solar module, including several double-sided battery sheets 101, upper glass and transparent backplane or glass, and the battery sheet They are connected through interconnection bars and bus bars 102 and are connected to the terminal post 3 of the heat-dissipating split junction box for solar modules through component lead-out lines. Several battery pieces 101 are vertically divided into groups. In this embodiment, each The module includes 60 double-sided battery pieces, and the battery pieces are divided into 6 groups longitudinally, and each group includes 10 double-sided battery pieces 101. The solar modules are connected by a heat dissipation split junction box, an intermediate junction box 20 is connected in the middle of every two groups of cells, and the edges of a group of cells on both sides of the modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com