Technology for manufacturing interlaced back contact (IBC) crystalline silicon solar battery with ion implantation

A technology of solar cells and ion implantation, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of inability to accurately control the doping concentration and position, unfavorable mass production, complex costs, etc., to achieve battery preparation The process is simplified, it is beneficial to mass production, and the effect of increasing the output current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

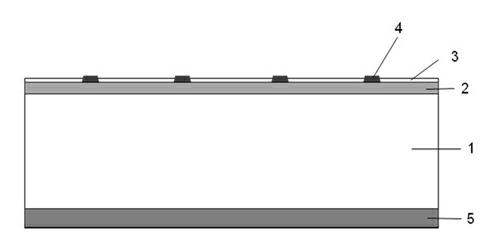

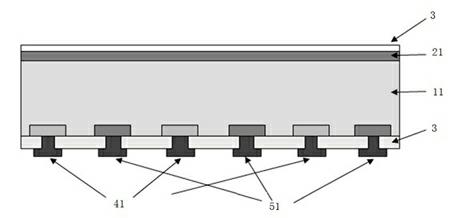

[0048] This example provides a process for fabricating a staggered back contact IBC battery by ion implantation, and the battery structure obtained is shown in the attached figure 2 shown, including the following steps:

[0049] (1) Suede corrosion

[0050] A p-type monocrystalline silicon substrate with a resistivity of 0.5-50 Ω·cm and a thickness of 50-500 is selected for surface texturing. For monocrystalline silicon substrates, surface texturing is carried out in 0.5~5% by weight sodium hydroxide deionized aqueous solution at a temperature of 75~90°C; for polycrystalline silicon substrates, surface texturing is carried out in nitric acid, hydrofluoric In the mixed solution of acid and deionized water with a volume ratio of 1~2:0.5~1:1, the surface texture is carried out under the condition of 5~15°C.

[0051] (2) Front ion implantation

[0052] Using the method of ion implantation, boron (B) doping is carried out on the front of the crystalline silicon substrate, the e...

Embodiment 2

[0068] This example provides a process for fabricating a staggered back contact IBC battery by ion implantation, and the battery structure obtained is as attached figure 2 shown, including the following steps:

[0069] (1) Suede corrosion

[0070] A p-type polysilicon substrate with a resistivity of 0.5-50 Ω·cm and a thickness of 50-500 is selected for surface texturing. For monocrystalline silicon substrates, surface texturing is carried out in 0.5~5% by weight sodium hydroxide deionized aqueous solution at a temperature of 75~90°C; for polycrystalline silicon substrates, surface texturing is carried out in nitric acid, hydrofluoric In the mixed solution of acid and deionized water with a volume ratio of 1~2:0.5~1:1, the surface texture is carried out under the condition of 5~15°C.

[0071] (2) Front thermal diffusion doping

[0072] The thermal diffusion doping method is used to do boron doping on the front side of the crystalline silicon substrate, the diffusion tempera...

Embodiment 3

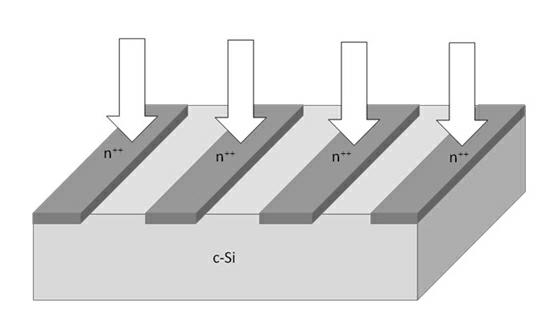

[0088] This example provides a process for fabricating staggered back-contact IBC cells by ion implantation, and the solar cell structure obtained is shown in the attached Figure 4 As shown, wherein 12 is an n-type silicon substrate, 22 is an n+ same-type doped layer, 3 is a passivation anti-reflection film, 42 is a p+ emitter, and 52 is an n+ base, including the following steps:

[0089] (1) Suede corrosion

[0090] Select an n-type single crystal silicon substrate with a resistivity of 0.5~50Ω·cm and a thickness of 50~500A for surface texturing. For monocrystalline silicon substrates, surface texturing is carried out in a sodium hydroxide solution with a weight percentage of 0.5~5% at a temperature of 75~90°C; for polycrystalline silicon substrates, surface texturing is carried out in nitric acid, hydrofluoric acid and In the mixed solution with the volume ratio of deionized water of 1~2:0.5~1:1, the surface texture is carried out under the condition of 5~15℃.

[0091] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com