High-speed precision crystal silicon laser etching apparatus and method

A technology of laser etching and process method, which is applied in the direction of laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problem that the production process of crystalline silicon cannot meet the development needs of solar energy technology, and achieve controllable processing graphics and processing paths, Effect of high precision and increased surface doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The process embodiment will be described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

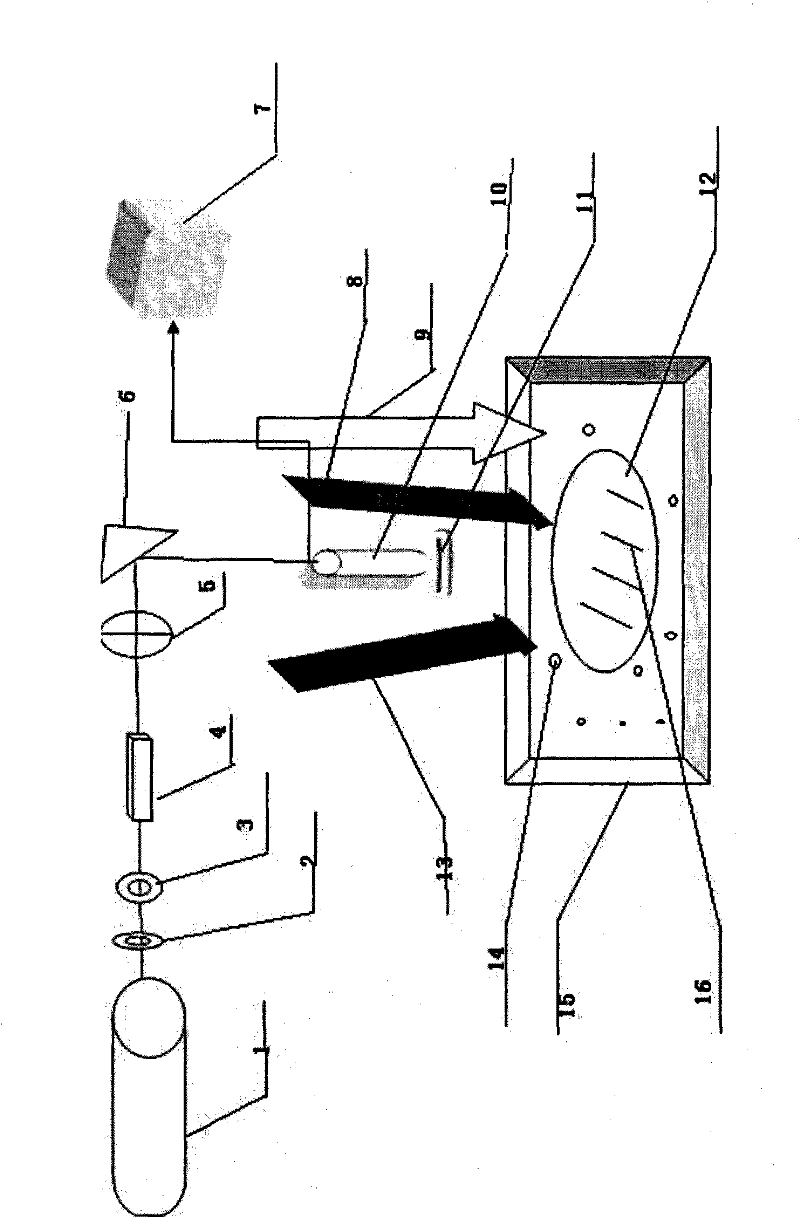

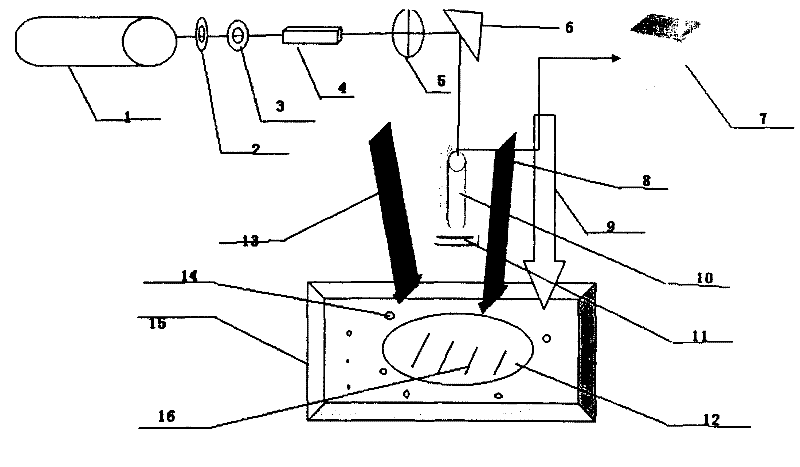

[0032] Such as figure 1 It is a schematic diagram of the structure of crystal silicon high-speed precision laser etching equipment. Before processing, the laser focus is on the upper surface of the silicon wafer. After the laser beam emitted by laser 1 passes through the shutter 2 and passes through the electric 1 / 2 filter 3, the beam can not be changed. If the polarization state is changed by 90 degrees, two kinds of vertical etching lines can be operated. After the laser beam enters the coaxial beam expander 4, the laser beam can be expanded to achieve what is required in the specially customized three-dimensional dynamic focusing galvanometer system 10. The required light incident diameter and beam divergence angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com