Electrode construction for enhancing photoelectric transforming efficiency of silicon solar cell

A technology for crystalline silicon solar cells and photoelectric conversion efficiency, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of reducing the photoelectric conversion efficiency of crystalline silicon solar cells, affecting the photoelectric conversion efficiency of crystalline silicon solar cells, and the photoelectric conversion efficiency of crystalline silicon solar cells. To solve the problems of large surface ratio, etc., to achieve the effect of facilitating interconnection, increasing arrangement density, and reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

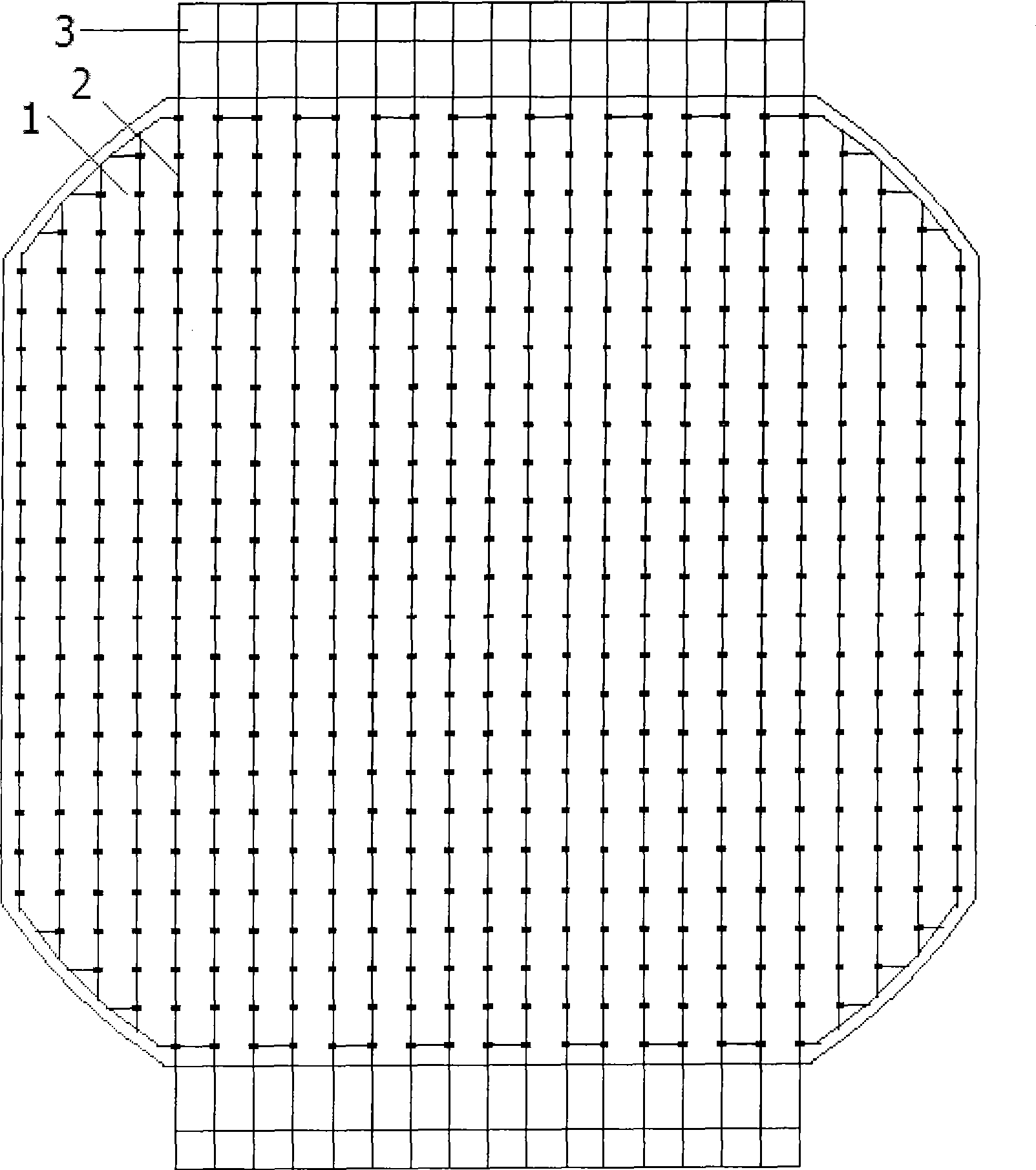

[0015] see figure 1 In this embodiment, a 125mm×125mm quasi-square battery is taken as an example. On the light-receiving surface of a crystalline silicon solar cell substrate, metal grid electrodes 2 arranged in parallel at a distance of 5 mm are arranged. Each metal grid electrode 2 is connected to the silicon solar cell substrate. At least two solder joints 1 are arranged between the light-receiving surfaces, and the distance between two adjacent solder joints 1 is 5 mm. The metal grid line 2 is silver-plated copper wire, and its resistivity is 1.7×10 -8 ohm m. On the side of the crystalline silicon solar cell substrate, there is a bus strip 3 welded to the lead end of the metal grid wire electrode 2. The bus strip 3 is a conductive metal strip. When another single solar cell is connected to it, only another The back electrode of the single solar cell can be welded to it.

[0016] The total number of solder joints in this embodiment is 585, and the density is 4 / cm 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com