Ink jet device for preparing superfine primary/secondary grid line of solar cell

A technology of solar cells and inkjet devices, applied in power transmission devices, printing, transfer materials, etc., can solve the problems of difficult control of aspect ratio, difficulty of thin grid line width less than 50 μm, waste of slurry and debris rate, etc. Achieve the effect of flexible and adjustable mechanism, improve photoelectric conversion efficiency and reduce debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

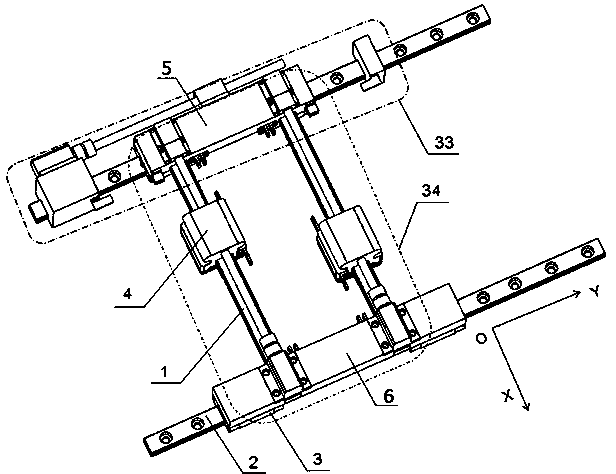

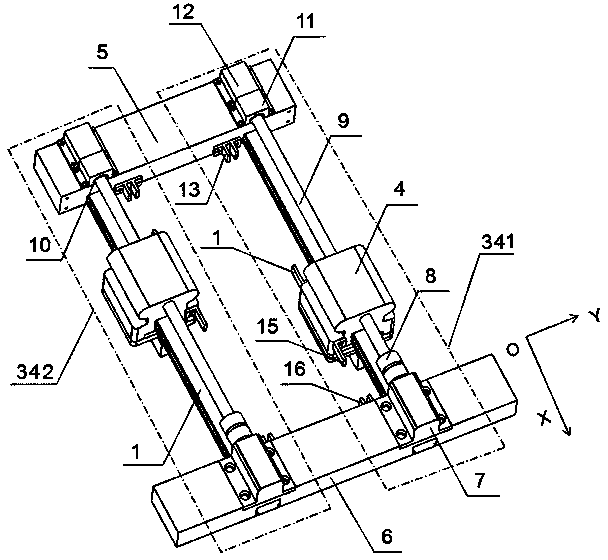

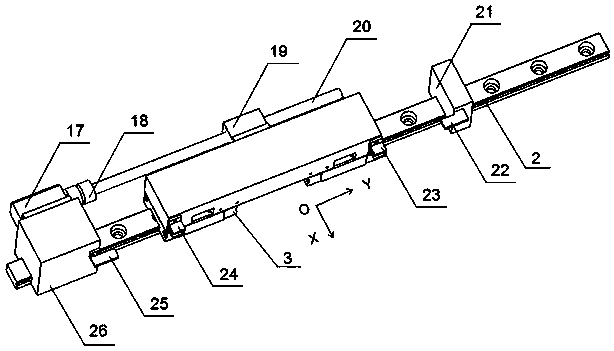

[0028] An inkjet device for preparing ultra-fine main and auxiliary grid lines of solar cells, such as Figure 1-Figure 5 As shown, it includes a linear guide rail, a guide rail mounting seat, a positioning mechanism, a micro-motion positioning platform and an inkjet print head array. The inkjet device is installed directly above the conveyor belt of the inkjet printing equipment.

[0029] like Figure 1-Figure 2 As shown, the linear guide rails include two sets of horizontal linear guide rails and two sets of longitudinal linear guide rails, and each set of horizontal linear guide rails is covered by the lateral sliding slider 4 through the groove of the horizontal linear slide rail 1 on the horizontal linear slide rails. 1, each group of longitudinal linear guide rails is composed of the two longitudinal sliding sliders 3 sleeved on the longitudinal linear guide rails 2 through the grooves of the longitudinal linear guide rails 2.

[0030] like Figure 1-Figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com