OLED display device and fabrication method thereof

A display device and display area technology, which is applied in the manufacturing of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problem that the camera area cannot be displayed, and achieves the improvement of imaging effect, transmittance, and reduction of occlusion area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

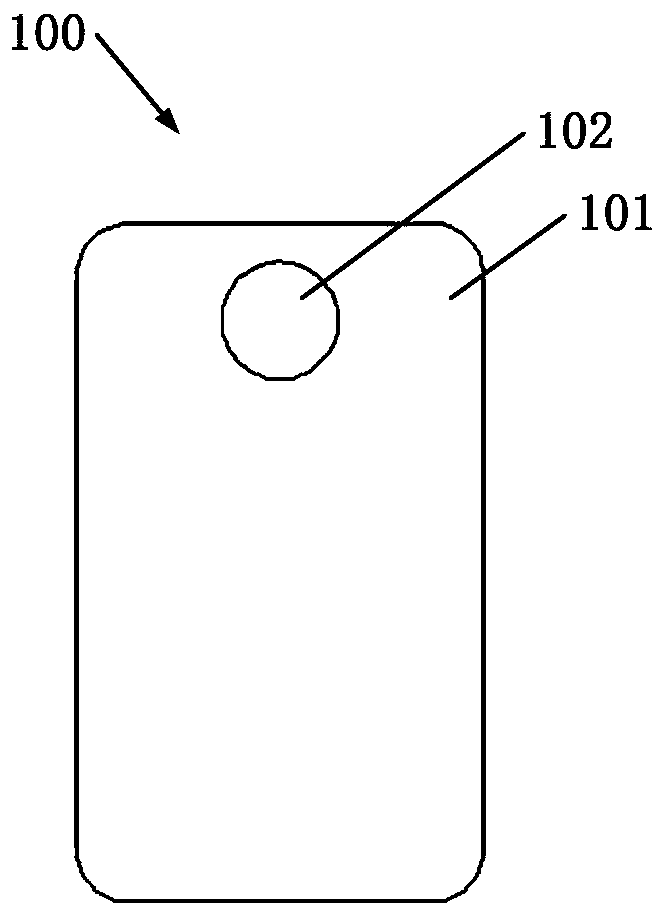

[0053] Such as figure 1 As shown, an OLED display device 100 is defined with a first display area 101 and a second display area 102 .

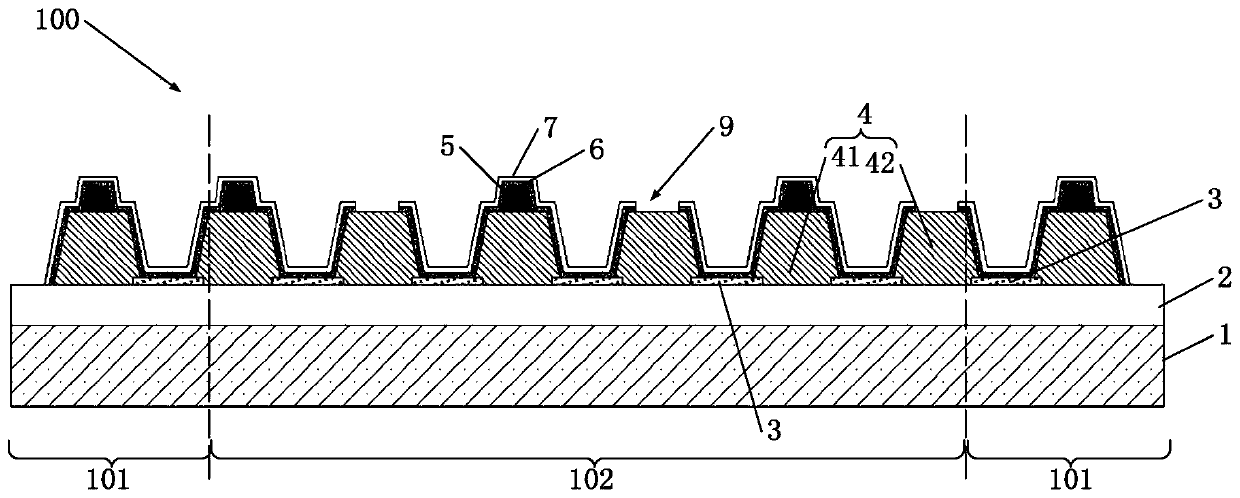

[0054] Such as figure 2 As shown, the OLED display device 100 shown therein comprises: a substrate 1 , a functional layer 2 , an anode 3 , a pixel definition layer 4 , a first isolation column 5 , a light emitting layer 6 and a cathode 7 . The functional layer 2 is disposed on the substrate 1 ; the anodes 3 are disposed on the functional layer 2 at intervals; the pixel definition layer 4 is disposed on the functional layer 2 between adjacent anodes 3 .

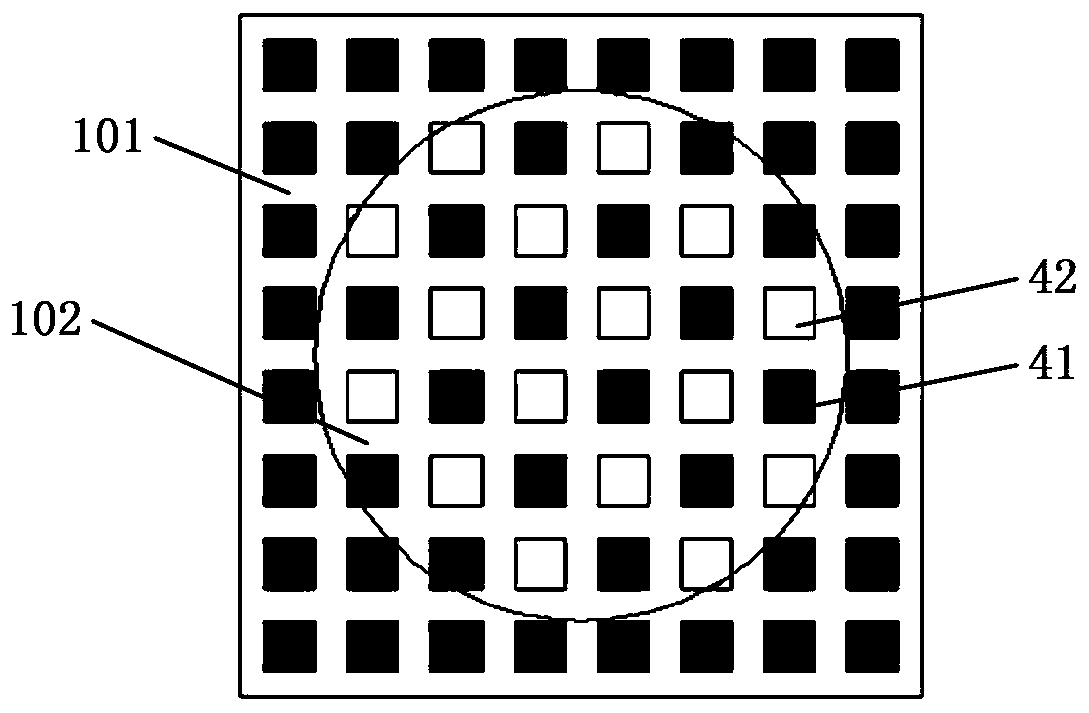

[0055] Such as figure 2 , image 3 As shown, the pixel definition layer 4 of the first display region 101 is provided with first isolation columns 5 . Wherein the pixel definition layer 4 located in the second display area 102 includes a first pixel definition layer 41 and a second pixel definition layer 42; the first isolation column 5 is arranged on the first pixel definition layer 41;...

Embodiment 2

[0059] In the following, only the differences between the present embodiment and the first embodiment will be described, and the similarities will not be repeated here.

[0060] Such as Figure 5 , Figure 6 As shown, there are two second pixel definition layers 42 arranged between the two adjacent first pixel definition layers 41. Thus, the shaded area of the cathode 7 can be reduced, the transmittance of the cathode 7 can be increased, and finally the lighting effect of the camera under the screen can be improved, and the imaging effect thereof can be improved.

Embodiment 3

[0062] In the following, only the differences between the present embodiment and the first embodiment will be described, and the similarities will not be repeated here.

[0063] Such as Figure 7 , Figure 8 As shown, there are three or more second pixel definition layers arranged between two adjacent first pixel definition layers. Thus, the shaded area of the cathode 7 can be reduced, the transmittance of the cathode 7 can be increased, and finally the lighting effect of the camera under the screen can be improved, and the imaging effect thereof can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com