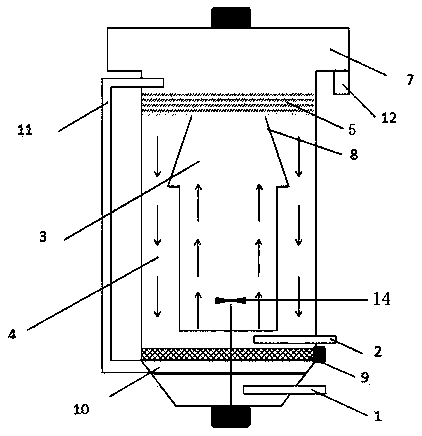

Defluorination method of fluorine-containing wastewater, and fluidized bed crystallization separator for defluorination

A technology of crystallization separation and fluidized bed, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as complex operating conditions, difficult separation, and difficult water discharge standards, and achieve good settling properties, fluorine Low ion concentration and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings, embodiments and comparative examples. It should be understood that these embodiments are only used to illustrate and explain the present invention and not to limit the scope of the present invention; after reading the content of the present invention, those skilled in the art make various changes or modifications to the present invention, and these equivalent forms are the same. It falls within the scope defined by the appended claims of this application.

[0027] The raw materials in the technical scheme of the present invention can be commercially available products, or self-made by conventional means.

[0028] In the present invention, if there is no explanation to the contrary, the directional words used such as "up, down, top, bottom" are usually for the directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com