Methods and materials for evaluating and improving the production of geo-specific shale reservoirs

a technology of geo-specific shale and reservoirs, applied in the direction of fluid removal, directional drilling, borehole/well accessories, etc., can solve the problems of production and surface processing problems, inefficient recovery,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

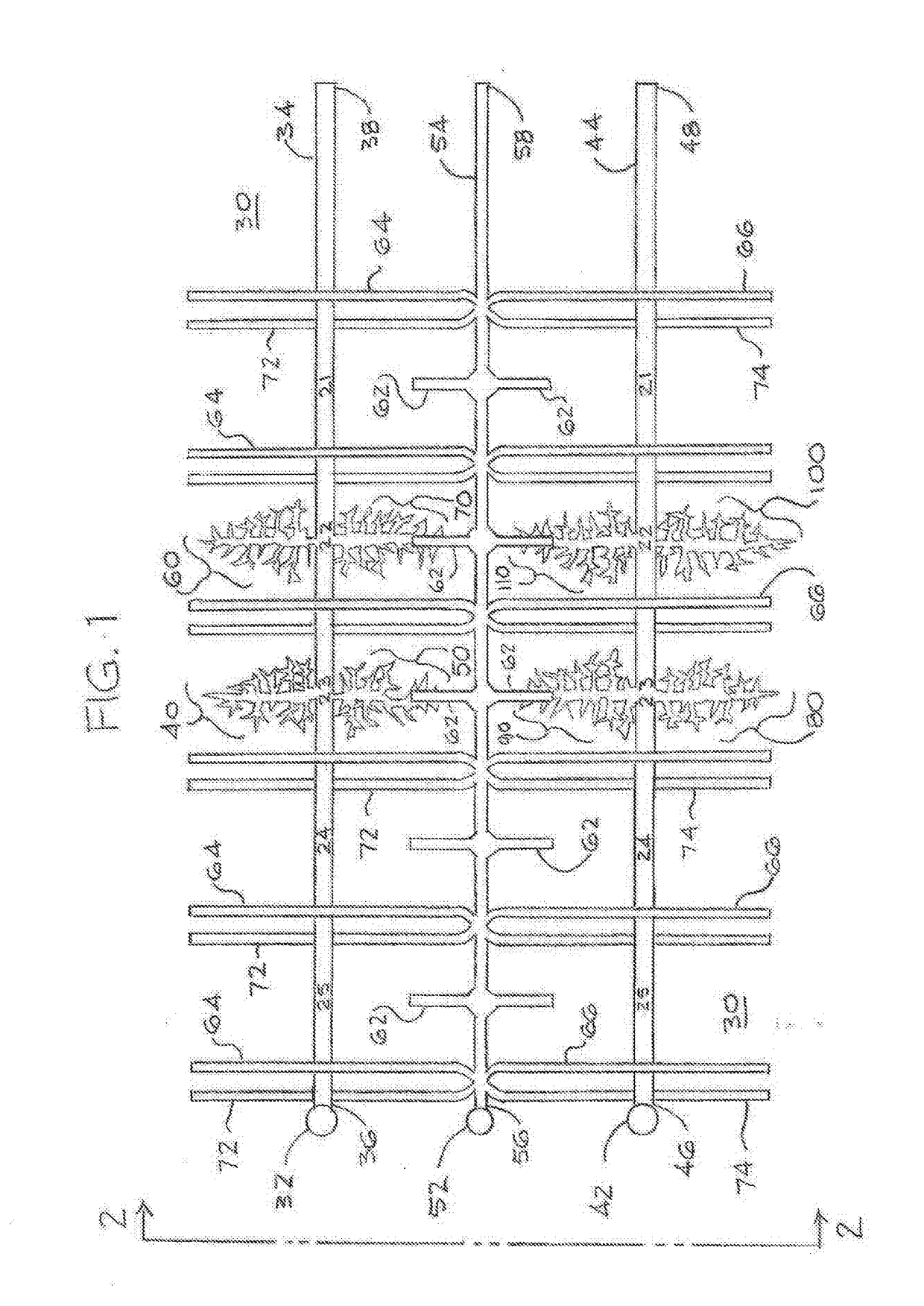

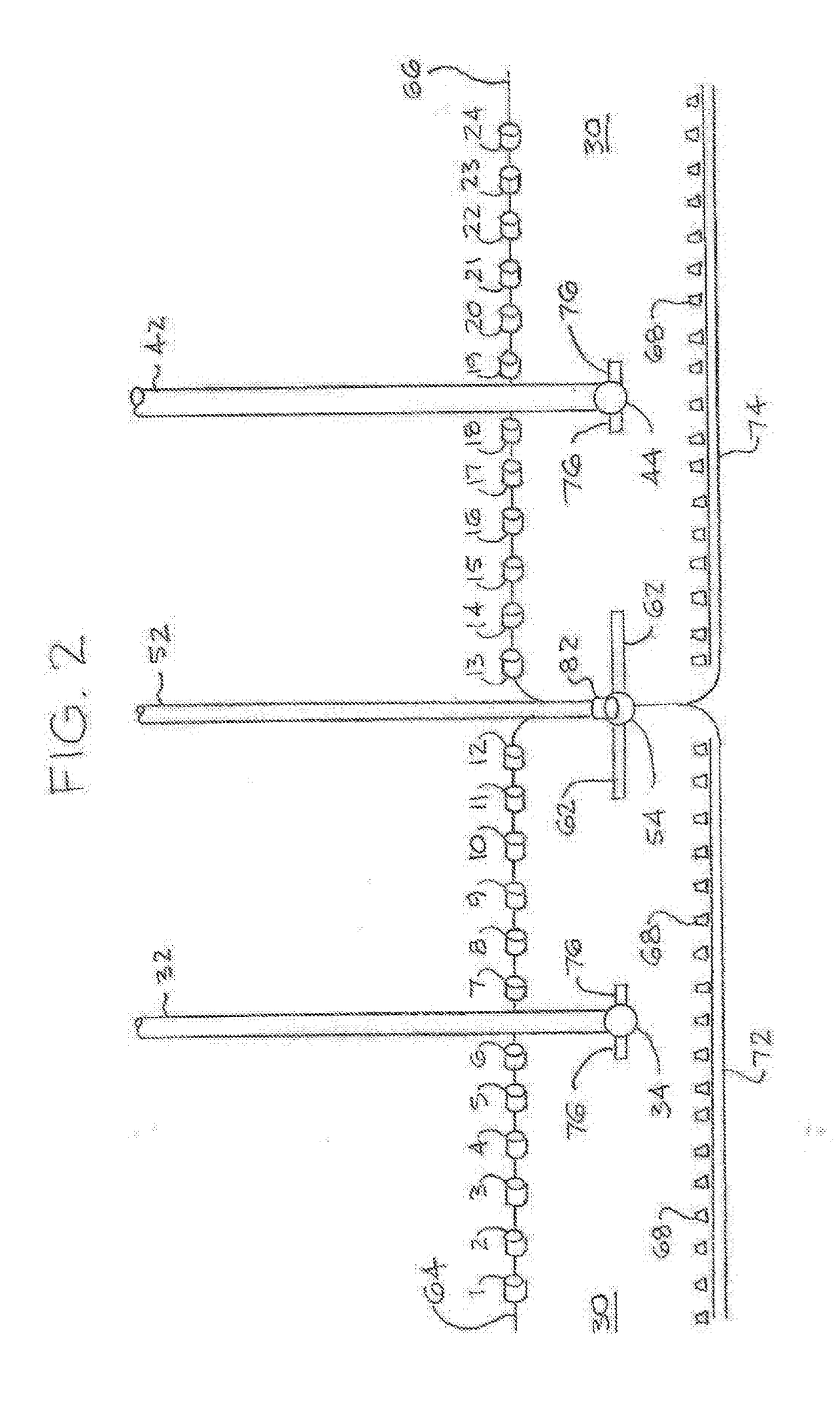

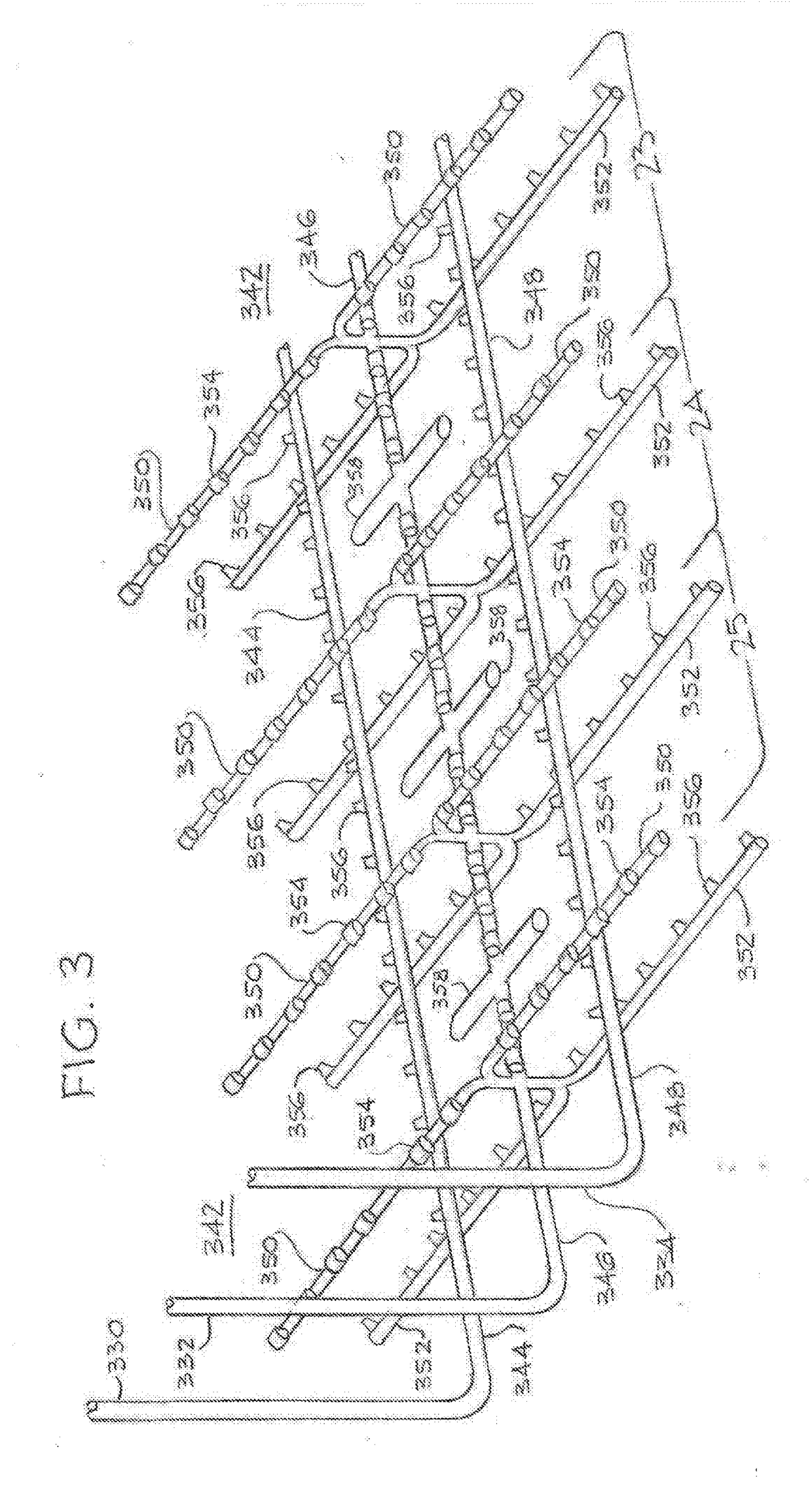

[0012]Obtaining hydrocarbon fluids from subterranean formations using a single wellbore or “mono-bore” approach, even implementing directional drilling and hydraulic fracturing, has a number of limitations, including, but not necessarily limited to, the primary method for obtaining information about the immediate environment of the single wellbore.

[0013]It has been discovered that the use of at least one diagnostic lateral wellbore adjacent or proximate to at least one primary lateral wellbore or another diagnostic lateral wellbore may provide a wealth of information, that is, empirical knowledge (defined herein as data) about the at least one primary lateral wellbore and / or diagnostic lateral wellbore and / or the subsurface volume surrounding these wellbores. As defined herein, in one non-limiting embodiment, assisting or diagnostic wellbores are lateral wellbores drilled for performing diagnostic-based treatments within one or more fracturing interval locations along the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com