Method for separating and recovering chlorine and oxygen of hydrogen chloride oxidation gas mixture by use of PSA (Pressure Swing Adsorption) technology

A separation and recovery, pressure swing adsorption technology, applied in the field of separation of chlorine and oxygen, selective separation and recovery of chlorine and oxygen, can solve the problems of difficult reactor design, restricting industrialization, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

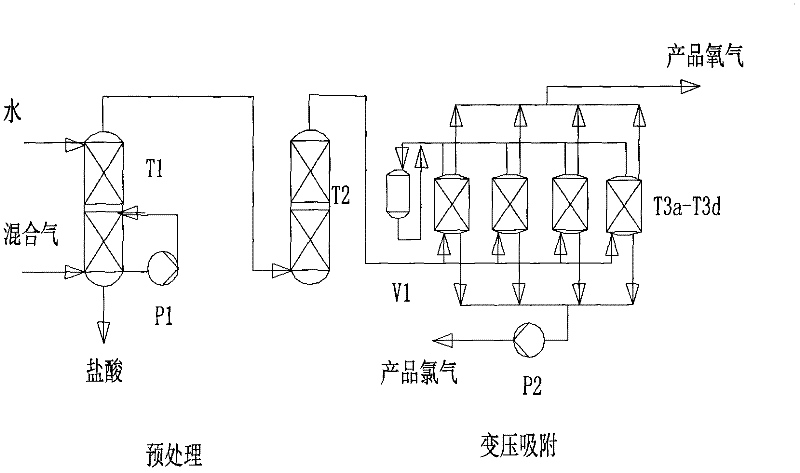

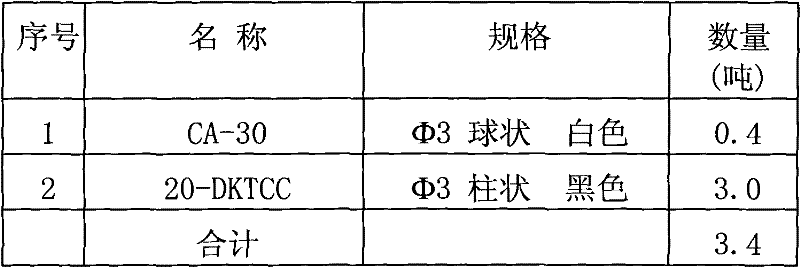

[0071] This example is a four-tower pressure swing adsorption method for hydrogen chloride oxidation mixed gas separation and recovery of chlorine and oxygen. The raw material gas composition (treated by hydrogen chloride removal device and drying device) and flow rate are shown in Table 2.

[0072] Table 2 Composition and flow rate of hydrogen chloride oxidation mixed gas after pretreatment

[0073]

[0074]

[0075] The pressure swing adsorption system in this example consists of 4 adsorption towers, 1 vacuum pump and corresponding program-controlled valves and pipelines. One of the adsorption towers is in the state of adsorption, one is in the state of vacuum regeneration, and the other two are in the state of equalizing pressure. The process of this example adopts one time of equalizing pressure. The adsorption pressure is 0.3MPa gauge pressure, and the adsorption temperature is normal temperature.

[0076] After pretreatment, the raw material mixed gas (basically c...

Embodiment 2

[0080] This example is a four-tower pressure swing adsorption method for hydrogen chloride oxidation mixed gas separation and recovery of chlorine and oxygen. The raw material gas composition (treated by hydrogen chloride removal device and drying device) and flow rate are shown in Table 4.

[0081] Table 4 Composition and flow rate of hydrogen chloride oxidation mixed gas after pretreatment

[0082]

[0083] The pressure swing adsorption system of this example is the same as that of Example 1. One of the adsorption towers is in the adsorption state, one is in the vacuum regeneration state, and the other two are in the pressure equalization state. The process of this example uses two pressure equalizations. The adsorption pressure is 0.5MPa gauge pressure, and the adsorption temperature is normal temperature.

[0084] The pressure swing adsorption process in this example is basically the same as Example 1 except for the number of pressure equalizations. The resulting prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com