Method for continuously preparing toluene diisocynate

A technology of toluene diisocyanate and toluene diamine, applied in the field of continuous preparation of toluene diisocyanate, can solve the problems of increasing production cost, increasing TDI production cost, burden of slag removal system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

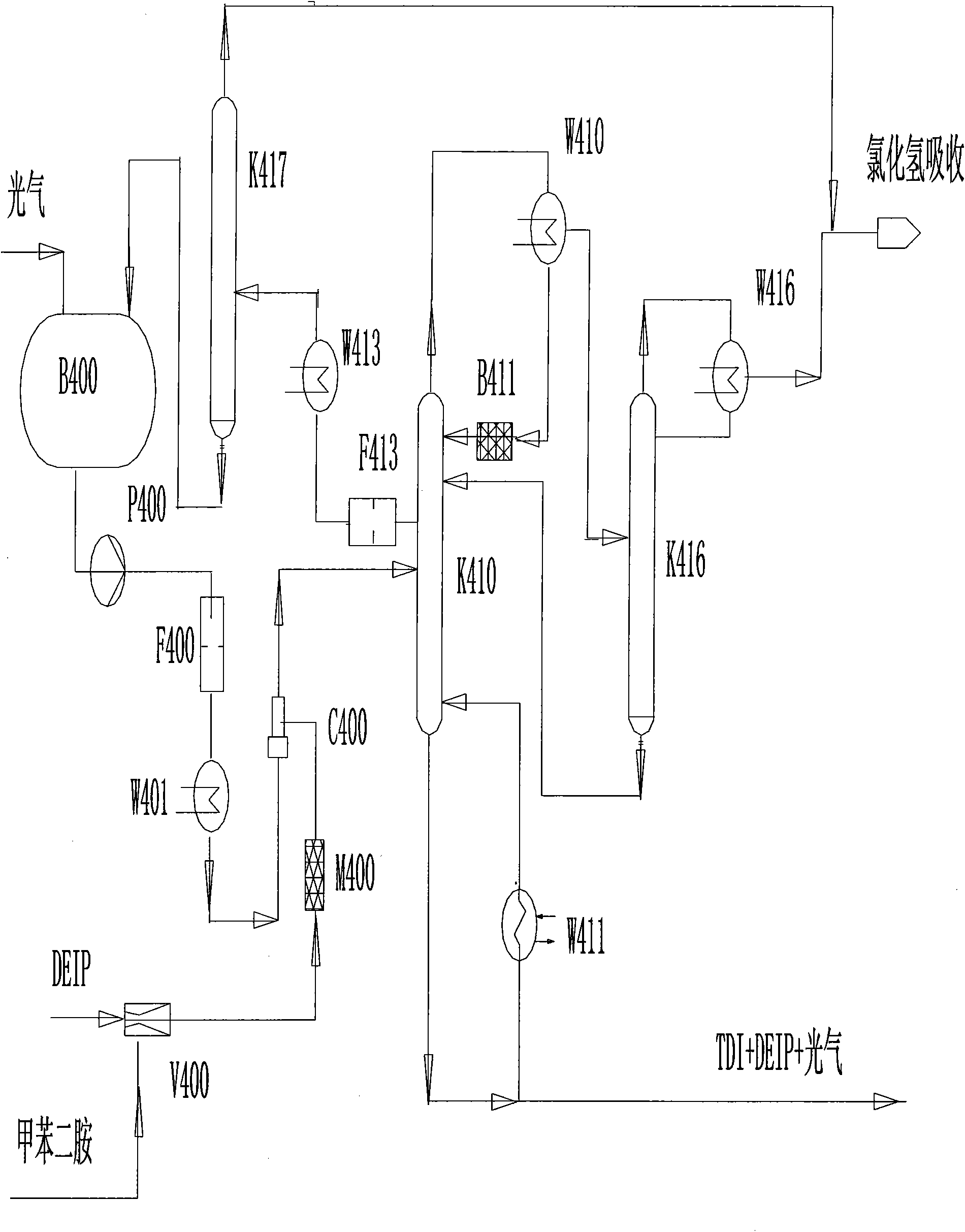

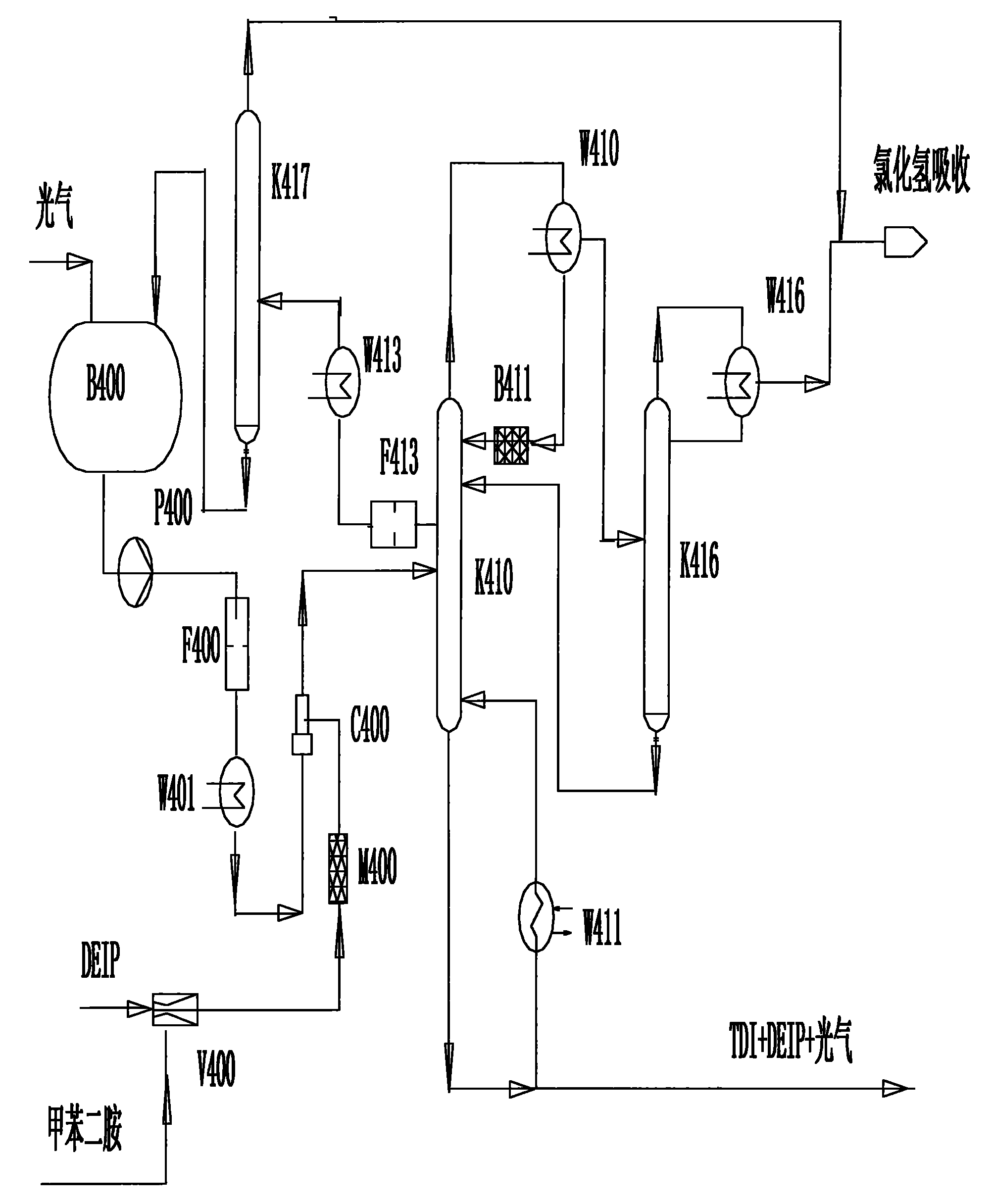

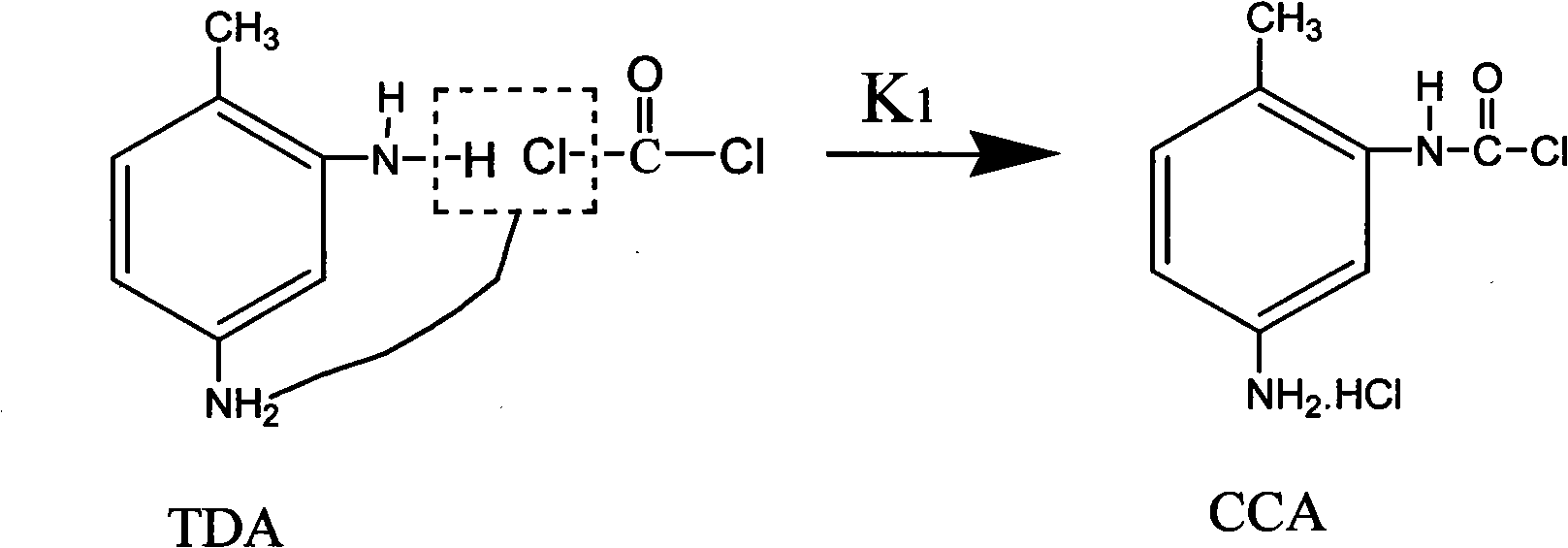

[0040] According to the ratio of phosgene and toluenediamine 4: 1 (molar ratio), use phosgene pump P400 to add -5 ℃ liquid phosgene into the jet reactor C400, and enter the reaction zone of the jet reactor by rotary atomization from the outlet end of the nozzle; 120 The DEIP solution of 21% toluene diamine at °C is input into the injector C400, and the mixed reaction is carried out at the reaction zone of the jet reactor, the reaction temperature is about 100 °C, and the pressure at the feeding port is 2.05MPa. The mixed solution of toluene dicarbamoyl chloride, solvent DEIP and excess phosgene obtained after the reaction in the jet reactor enters the thermal photochemical reaction tower K410 at the fifth tray, and the bottom of the tower is heated. The liquid level of the K410 tower tank is 50%, and the operation The temperature at the top of the tower is 80°C, the pressure is 1.5MPa, the bottom of the tower is 160°C, and the temperature in the middle of the tower is 85°C. To...

Embodiment 2

[0044] The mixed solution of 15% toluenediamine and DEIP at 110°C and the liquid phosgene at -10°C were respectively introduced into the ejector reactor, the molar ratio of the reactants toluenediamine to phosgene was 1:1.5, and the reaction temperature was controlled at 90°C. The operating pressure is 1.5MPa, the reaction solution is transferred from the outlet of the jet reactor C400 to the bottom of the tower reactor K410, the temperature at the bottom of the tower is 148°C, the temperature at the top of the tower is 80°C, and the top product is a mixture of phosgene and hydrogen chloride gas. The temperature in the middle is 95°C, and the pressure inside the tower is 2MPa. More than 90% of high-purity phosgene can be separated and recovered in the tower.

[0045] The process conditions of reactor and tower are controlled in the following table:

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com