Method for processing fly ash used for circulating fluidized bed

The technology of a circulating fluidized bed and a treatment method is applied in the field of high-value utilization of fly ash, which can solve the problems of difficulty in generating economic benefits, low resource utilization rate, low dissolution rate, etc. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

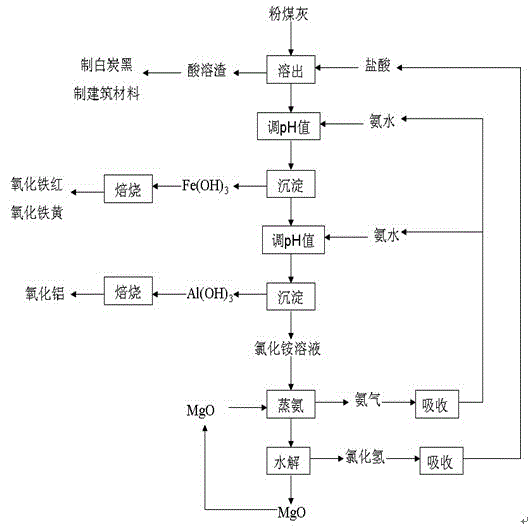

Image

Examples

Embodiment 1

[0027] (1) Grind the fly ash of a circulating fluidized bed in a certain place (see Table 1 for the chemical composition) to 200 mesh. Mix 1 kg of ground fly ash with 1.8 kg of concentrated hydrochloric acid with a mass fraction of about 35%, react for 1.5 hours, and filter to obtain filter residue and leaching solution. The filter residue was reversely washed with water, and further processed to obtain white carbon black, and the extraction rate of silicon was calculated to be 97%.

[0028] (2) Use ammonia water to adjust the pH value of the leaching solution to 3.2, precipitate at 50°C for 3 hours, and then filter with a filter to obtain the filter residue and filtrate. The filter residue is washed with water and dried at 100°C to obtain iron oxide yellow. Iron oxide yellow was burned at 260°C to obtain iron oxide red, and the extraction rate of iron was calculated to be 78%.

[0029] (3) Use ammonia water to adjust the pH value of the filtrate after iron extraction to 5.1,...

Embodiment 2

[0034] (1) Grind a circulating fluidized bed fly ash whose chemical composition is shown in Table 1 to 250 mesh. Mix 1 kg of ground fly ash with 1.5 kg of concentrated hydrochloric acid with a mass fraction of about 34%, react at 100°C for 1 hour, and filter to obtain filter residue and leaching solution. The filter residue was reversely washed with water, and further processed to obtain white carbon black, and the extraction rate of silicon was calculated to be 96%.

[0035] (2) Use ammonia water to adjust the pH value of the leaching solution to 2.2, and filter it with a filter after settling at 50°C for 3 hours to obtain the filter residue and filtrate. The filter residue is washed and dried at 100°C to obtain iron oxide yellow, which is oxidized Iron yellow was burned at 260°C to obtain iron oxide red, and the extraction rate of iron was calculated to be 55%.

[0036] (3) Use ammonia water to adjust the pH value of the filtrate after iron extraction to 4.4, and filter it ...

Embodiment 3

[0039] (1) Grind a circulating fluidized bed fly ash whose chemical composition is shown in Table 1 to 300 mesh. Mix 1 kg of ground fly ash with 2 kg of concentrated hydrochloric acid with a mass fraction of about 36%, react at 150°C for 3 hours, and filter to obtain filter residue and leaching solution. The filter residue was reversely washed with water, and further processed to obtain white carbon black, and the extraction rate of silicon was calculated to be 97%.

[0040] (2) Use ammonia water to adjust the pH value of the leaching solution to 3.5, and filter it with a filter after settling at 50°C for 3 hours to obtain the filter residue and filtrate. The filter residue is washed and dried at 100°C to obtain iron oxide yellow, which is oxidized Iron yellow was burned at 260°C to obtain iron oxide red, and the extraction rate of iron was calculated to be 81%.

[0041] (3) Use ammonia water to adjust the pH value of the filtrate to 5.1, precipitate at 50°C for 3 hours and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com