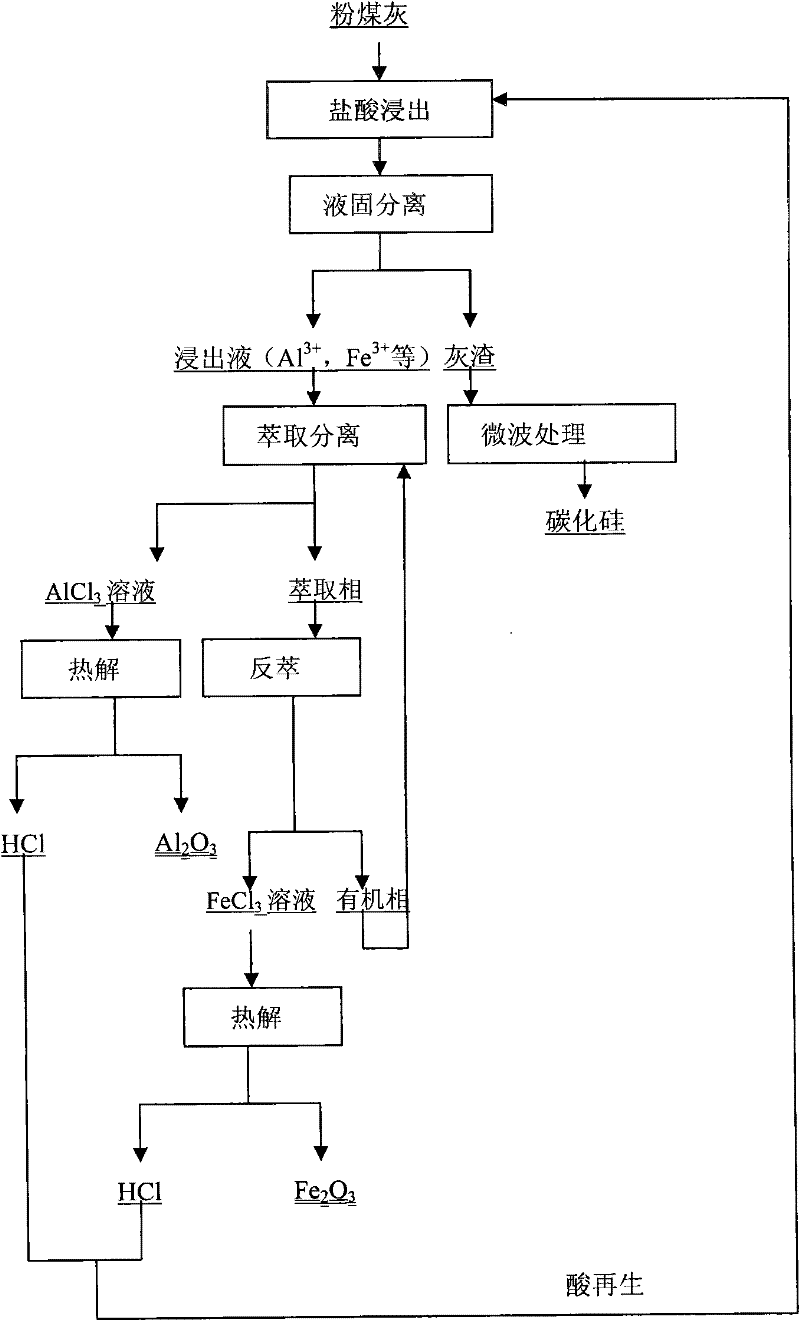

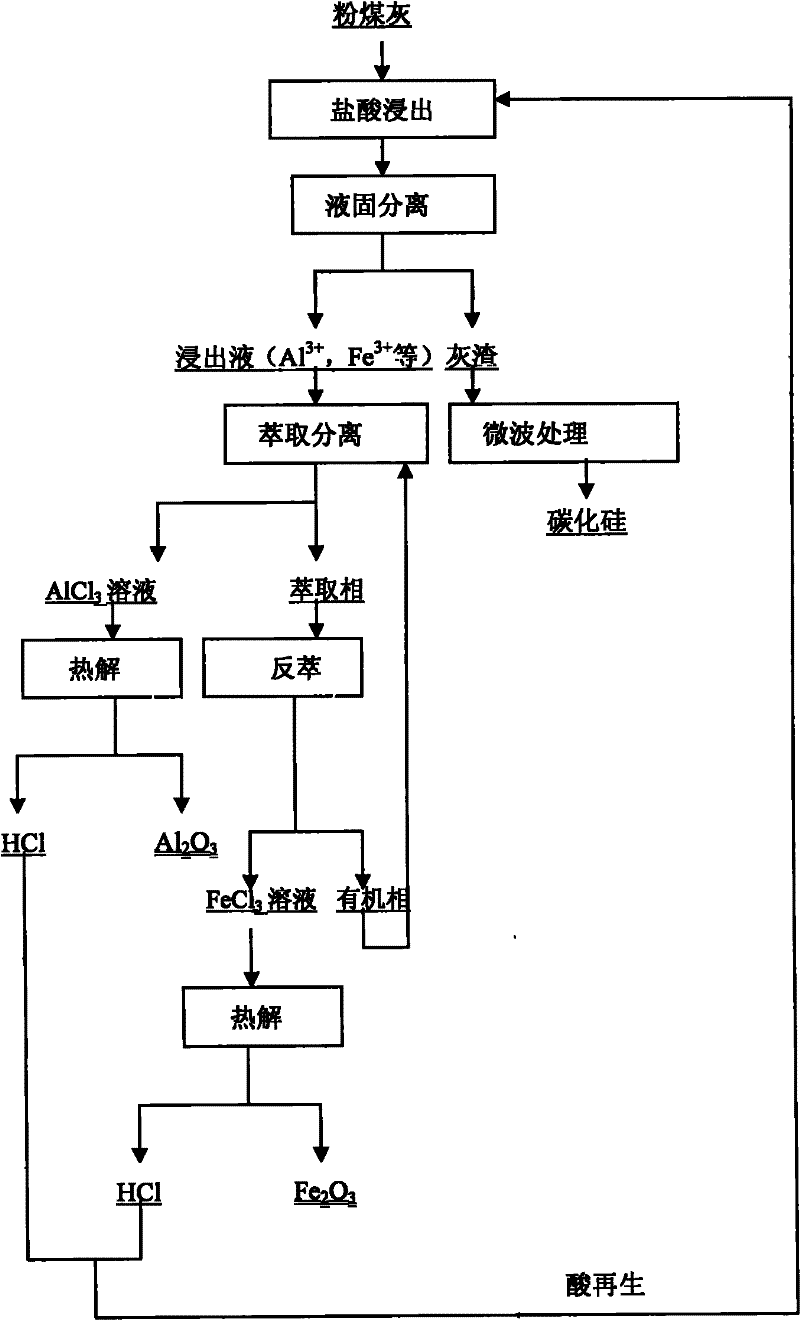

Ecological synthetic utilization method of fly ash

A fly ash, ecological technology, applied in the field of fly ash ecological comprehensive utilization, can solve the problems of complex process flow, high equipment requirements, large pollution by fluoride solubilization method, etc., and achieves a short process flow and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The main component of fly ash is Al by weight percentage 2 o 3 20%, Fe 2 o 3 25%, SiO 2 50%; the fly ash is ground to below 200 mesh, mixed with a 5% hydrochloric acid solution at a liquid-solid ratio of 40:1L / kg, and then leached at a leaching temperature of 100°C for 120 minutes. Under this condition, the pulverized coal The leaching rate of aluminum element in the ash is 90.35%, and the leaching rate of iron element is 93.2%. 2 The mass content is 92.08%.

[0029] Use tributyl phosphate as extractant, sulfonated kerosene as diluent to separate iron and aluminum elements in the leachate, the volume ratio of organic phase (extractant and diluent) to water is 1:1, diluent in extractant The volume fraction is 70%, extract at normal temperature for 1min, obtain the extract phase and the raffinate phase after extraction, aluminum enters the raffinate extract phase to form an aluminum chloride solution, and iron enters the extract phase; the aluminum chloride soluti...

Embodiment 2

[0036] The main component of fly ash is Al by weight percentage 2 o 3 25%, Fe 2 o 3 40%, SiO 2 30%, the fly ash is ground to below 200 mesh, mixed with 30% hydrochloric acid solution at a liquid-solid ratio of 3:1L / kg, and then leached at a leaching temperature of 180°C for 30 minutes. The leaching rate of aluminum element in coal ash is 97.17%, and the leaching rate of iron element is 96.26%. 2 The mass content is 95.31%.

[0037] Use tributyl phosphate as extractant and sulfonated kerosene as diluent to separate iron and aluminum elements in leachate, the volume ratio of organic phase to water phase is 4:1, and the volume fraction of diluent in extractant is 50% , extract at room temperature for 15 minutes, obtain the extract phase and the raffinate phase after extraction, aluminum enters the raffinate phase to form an aluminum chloride solution, and iron enters the extract phase; the aluminum chloride solution and the extract phase are separated.

[0038] The extra...

Embodiment 3

[0044] The main component of fly ash is Al by weight percentage 2 o 3 30%, Fe 2 o 3 15%, SiO 2 50%, the fly ash is ground to below 200 mesh, mixed with 20% hydrochloric acid solution at a liquid-solid ratio of 10:1L / kg, and then leached for 360min at a leaching temperature of 150°C. Under this condition, the powder The leaching rate of aluminum element in coal ash was 96.44%, and the leaching rate of iron element was 95.19%. After leaching, the leach solution is separated from the leaching residue by filtering, and the SiO in the leaching residue 2 The mass content is 94.17%.

[0045] Use tributyl phosphate as extractant and sulfonated kerosene as diluent to separate iron and aluminum elements in leachate, the volume ratio of organic phase to water phase is 2:1, and the volume fraction of diluent in extractant is 70% , extract at room temperature for 5 minutes, obtain the extract phase and the raffinate phase after extraction, aluminum enters the raffinate phase to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com