Bamboo charcoal polyurethane foam composite material and production method thereof

A technology of polyurethane foam and composite materials, which is applied in the field of polyurethane foam composite materials, can solve the problems of high proportion, easy breeding of germs, and affecting the original characteristics of sponges, etc., to achieve the effect of clean air and promote blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

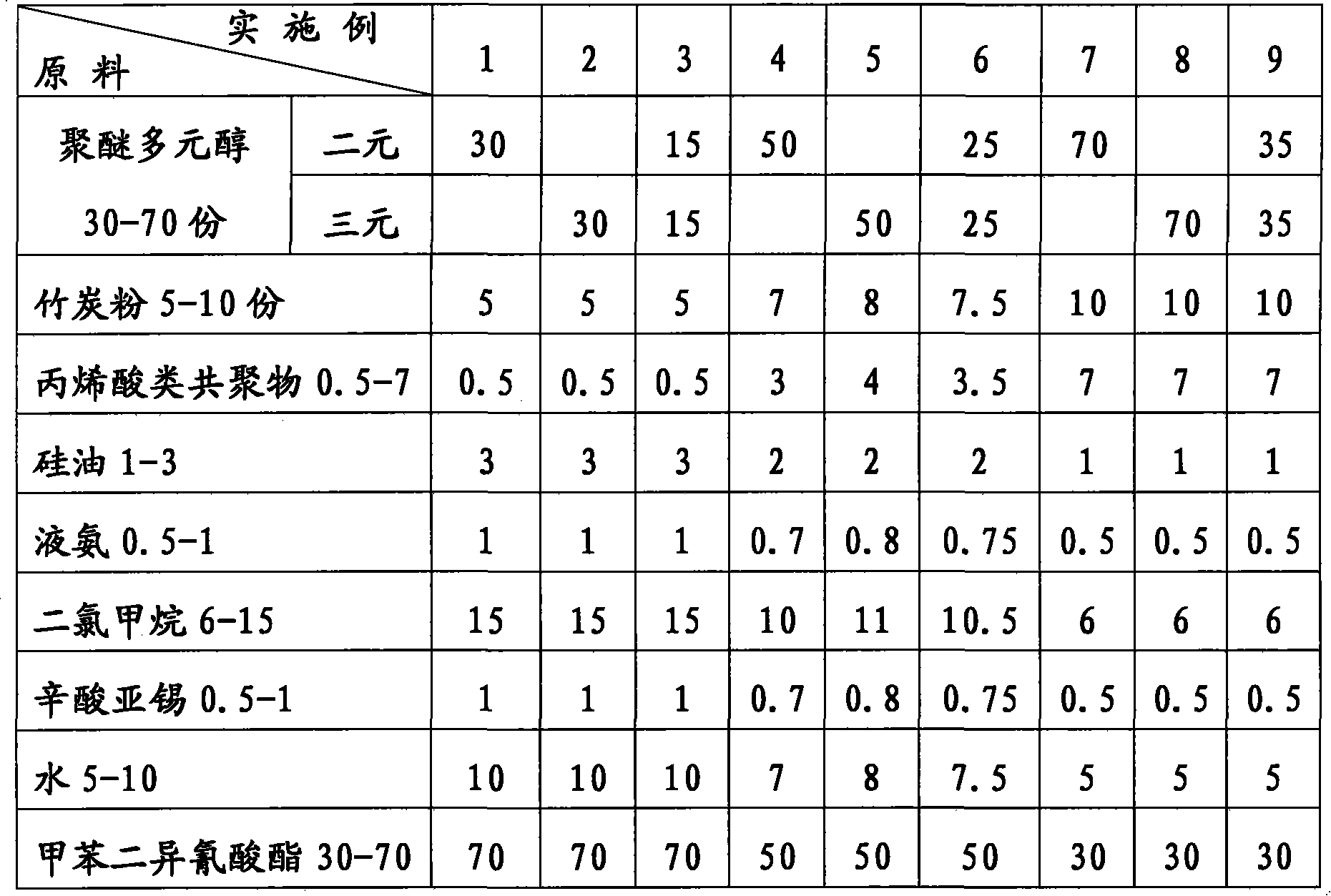

[0013] The present invention is further described the present invention with several representative examples below: in the raw material of application and weight portion proportioning thereof, amount is maximum be polyether polyol and toluene diisocyanate, each accounts for 30-70 weight portion (below the same) ), which is determined according to the density requirements of the foam composite material. If the density is high, the proportion of polyether polyol should be increased, and the proportion of toluene diisocyanate and other foaming aids should be reduced. If the density is low, the opposite is true.

[0014]

[0015] (Note: The binary and ternary in the table are the abbreviations of polyether diol and polyether triol respectively)

[0016] The production steps of this foam composite material are: (1) the production of bamboo charcoal powder: the bamboo is split into fragments less than 30cm in length or with bamboo processing waste except sawdust, placed in a carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com