Method for recycling phosgene in continuous production process of toluene di-isocyanate

A technology for the production process of toluene diisocyanate, which is applied in the field of phosgene recovery in the continuous production process of toluene diisocyanate, can solve the problems of high cost, high risk, and high toxicity of phosgene in the phosgene recovery process, and achieve reduced operation and Maintenance costs, investment reduction, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

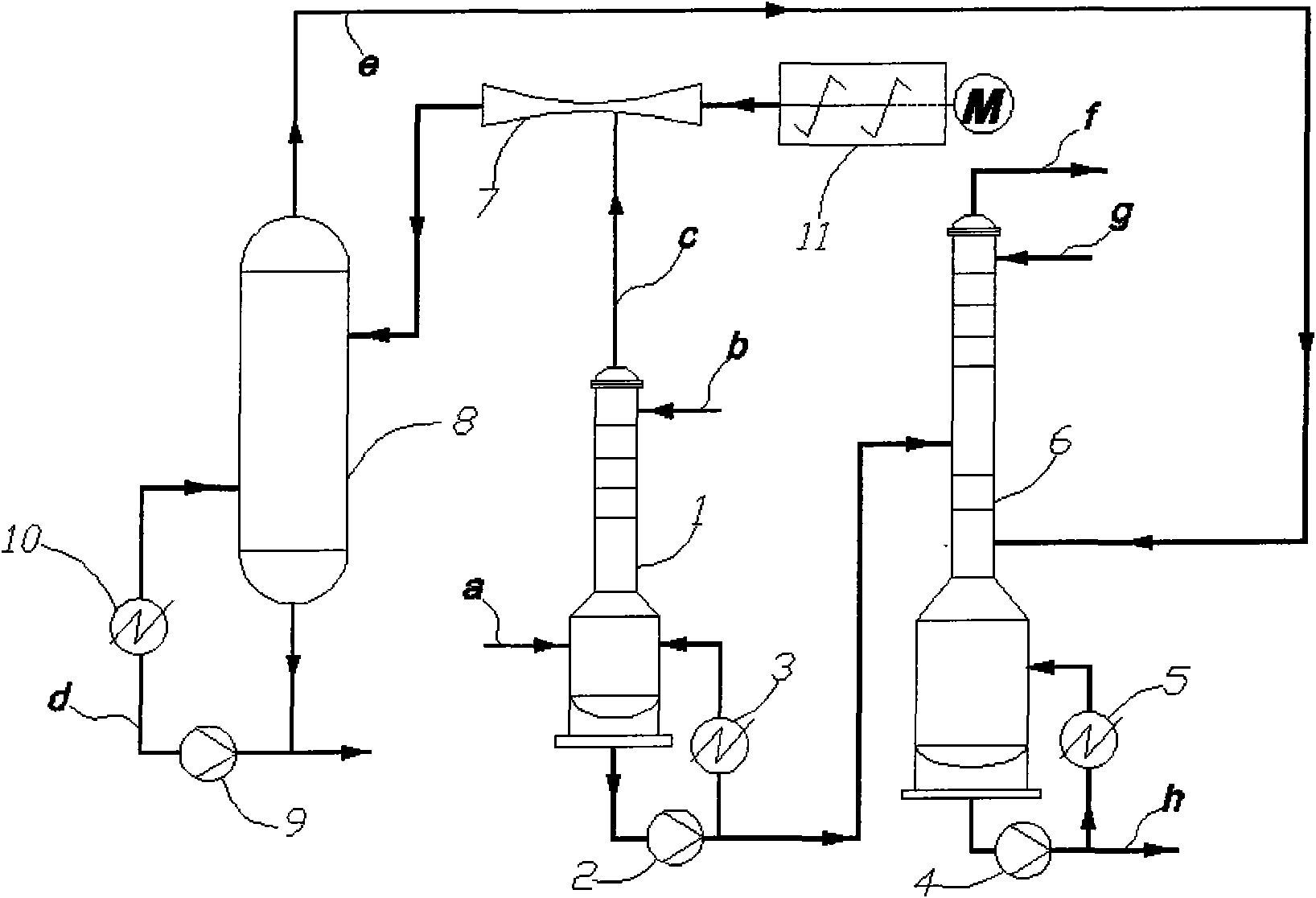

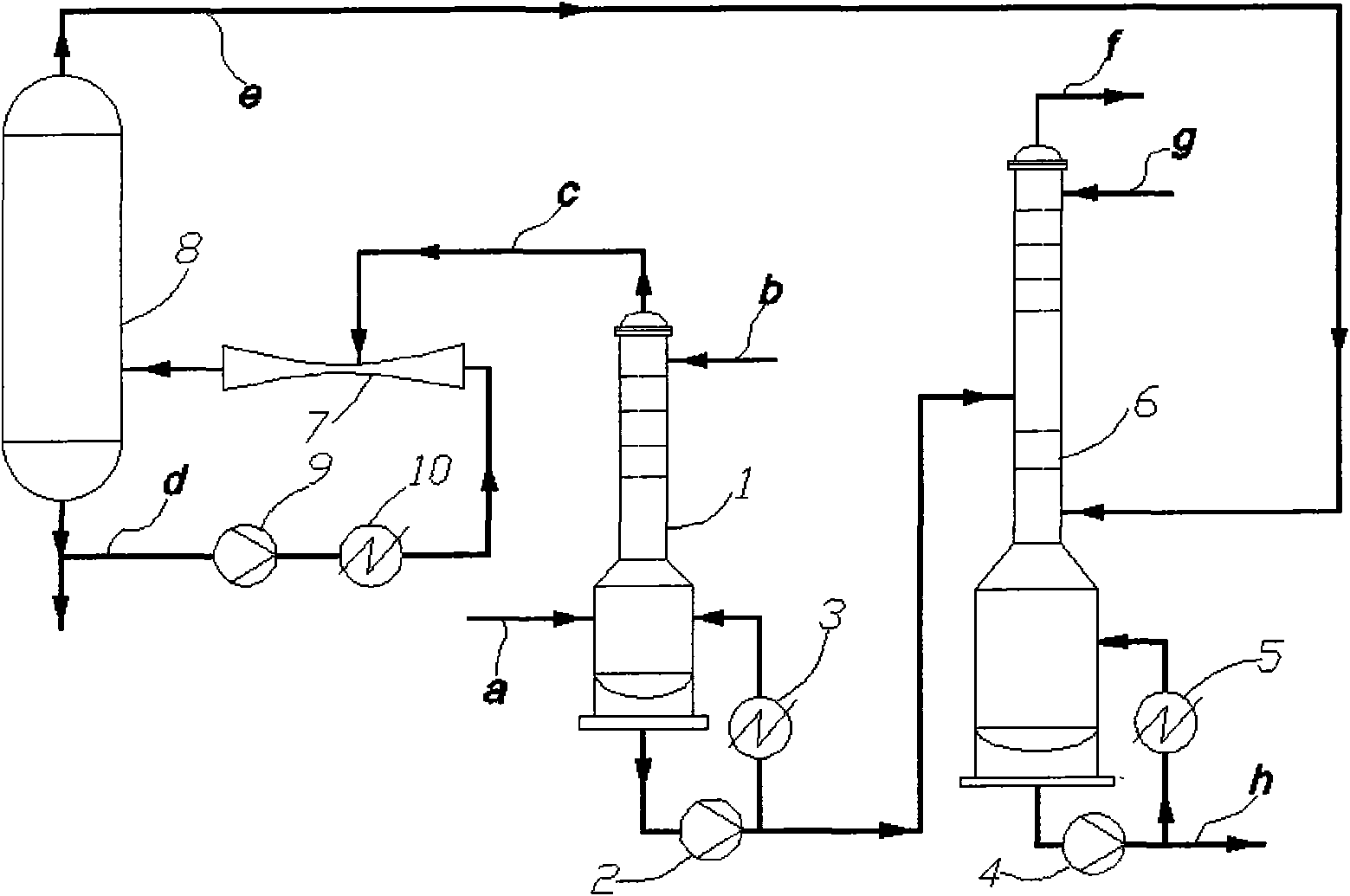

[0031] Embodiment 1 (this embodiment only illustrates a kind of concrete situation that the present invention implements and does not limit the present invention.)

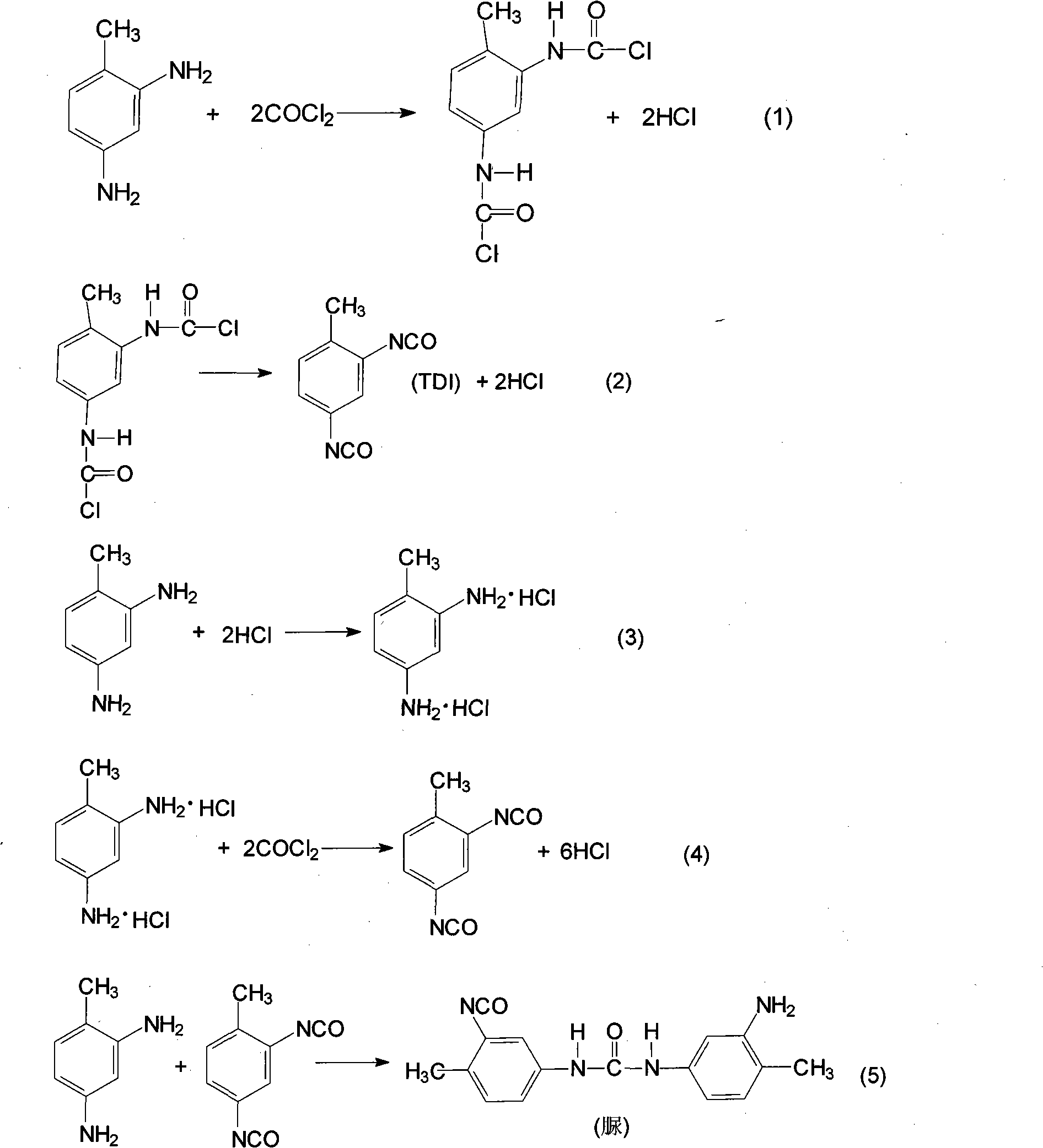

[0032] This example is the recovery of phosgene during the liquid-phase phosgenation of toluene diamine in o-dichlorobenzene (ODCB) to continuously prepare toluene diisocyanate (TDI). The percentage composition in each stream refers to the mass percentage.

[0033]The first phosgene absorption tower is a spray tower, and the top of the tower is provided with a wire mesh demister to remove the liquid droplets in the tower gas; the gas stream a (from toluene) rich in phosgene, hydrogen chloride and a small amount of impurities The degassing tower and the hydrogen chloride stripping tower in the diisocyanate continuous production process) are 5 ℃, absolute pressure 0.12MPa, its mass flow rate is 5000kg / hr, containing 81.9% phosgene, 17.4% hydrogen chloride, 0.6% carbon tetrachloride and A small amount of ODCB and car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com