Antibacterial polyurethane wood floor paint

A wooden floor and polyurethane technology, applied in the paint manufacturing industry, can solve the problems of unfavorable home environment health, no antibacterial function of the paint film, and easy regeneration of bacteria, etc., to achieve a healthy living room environment, good fullness, and harmful substance content low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

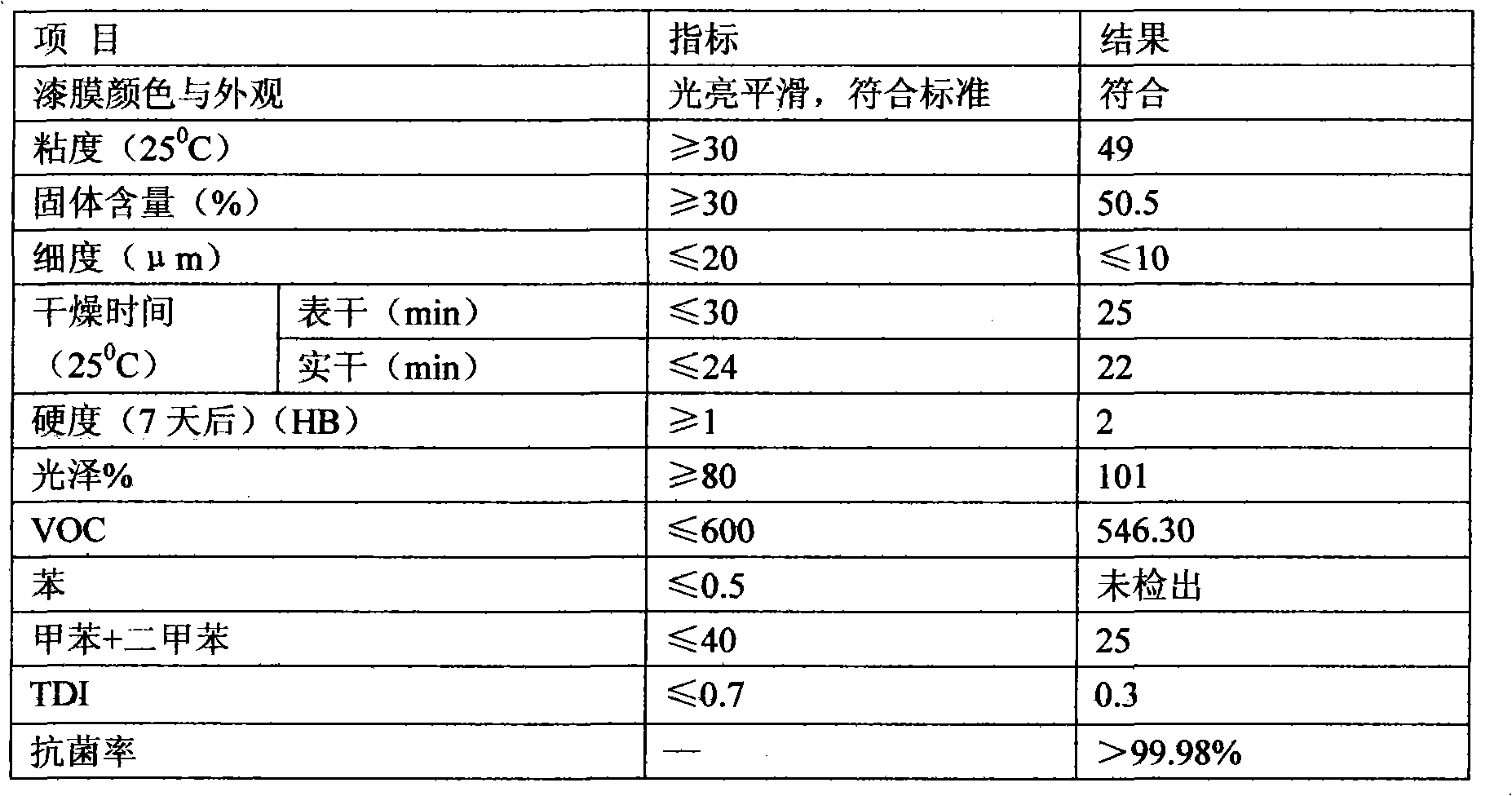

Examples

Embodiment 1

[0030] A kind of antibacterial polyurethane wood floor paint of the present invention, it is made up of A, hydroxyl component and B, NCO component two parts, wherein: A, the manufacture method of hydroxyl component are with 40kg coconut oil alkyd resin, 30kg castor Add sesame oil alkyd resin, 5kg cyclohexanone, 10kg n-butyl acetate, 11.95kg xylene, 2kg antibacterial agent, 0.5kg defoamer, 0.5kg leveling agent and 0.05kg drier into the high-speed disperser, and use 1000 Mix and disperse for about 15 minutes at a speed of ~1200 rev / min until the viscosity is 28±2S / ℃;

[0031] B. The NCO component is obtained by mixing and stirring 10kg xylene, 20kg n-butyl acetate, 20kg toluene diisocyanate and 50kg trimethylolpropane copolymer solution and then insulated for 1 hour;

[0032] The product of the present invention is obtained by mixing the above-mentioned components A and B uniformly at a weight ratio of 1:0.8 and then filtering.

Embodiment 2

[0034] A kind of antibacterial polyurethane wood floor paint of the present invention, it is made up of two parts of A, hydroxyl component and B, NCO component, wherein: the manufacture method of A, hydroxyl component is with 50kg coconut oil alkyd resin, 20kg castor Add sesame oil alkyd resin, 7kg cyclohexanone, 13kg n-butyl acetate, 9.19kg xylene, 0.5kg antibacterial agent, 0.1kg defoamer, 0.2kg leveling agent and 0.01kg drier into the high-speed disperser, and Mix and disperse at a speed of 1000-1200 rpm for about 15 minutes until the viscosity is 28±2S / ℃;

[0035] B. The NCO component is obtained by mixing and stirring 10kg xylene, 10kg n-butyl acetate, 60kg toluene diisocyanate and 20kg trimethylolpropane copolymer solution and then insulated for 1 hour;

[0036] The product of the present invention is obtained by mixing the above two components A and B uniformly in a weight ratio of 1:1 and then filtering.

Embodiment 3

[0038] A kind of antibacterial polyurethane wood floor paint of the present invention, it is made up of two parts of A, hydroxyl component and B, NCO component, wherein: the manufacture method of A, hydroxyl component is with 45kg coconut oil alkyd resin, 25kg castor Add sesame oil alkyd resin, 6kg cyclohexanone, 12kg n-butyl acetate, 11.48kg xylene, 1kg antibacterial agent, 0.2kg defoamer, 0.3kg leveling agent and 0.02kg drier into the high-speed disperser, and use 1000 Mix and disperse for about 15 minutes at a speed of ~1200 rev / min until the viscosity is 28±2S / ℃;

[0039] B. The NCO component is obtained by mixing and stirring 30kg xylene, 30kg n-butyl acetate, 20kg toluene diisocyanate and 20kg trimethylolpropane copolymer solution and then insulated for 1 hour;

[0040] The product of the present invention is obtained by mixing the above-mentioned components A and B uniformly in a weight ratio of 1:1.2 and then filtering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com