Preparation and use of cation aqueous polyurethane emulsion

A water-based polyurethane, cationic technology, applied in the direction of water repellent addition, pulp raw material addition process, textiles and papermaking, etc., can solve the problems of limiting the application of cationic polymers, and achieve good sizing effect, related performance improvement, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

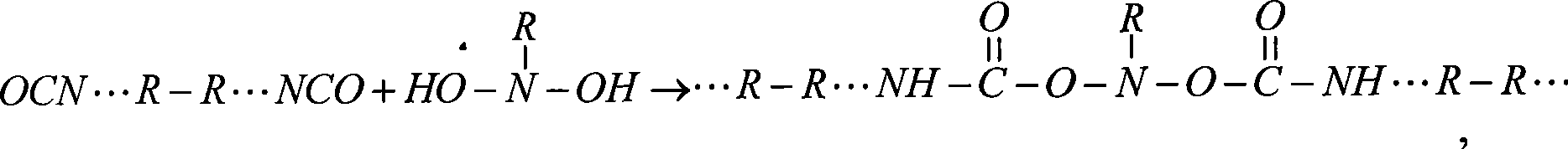

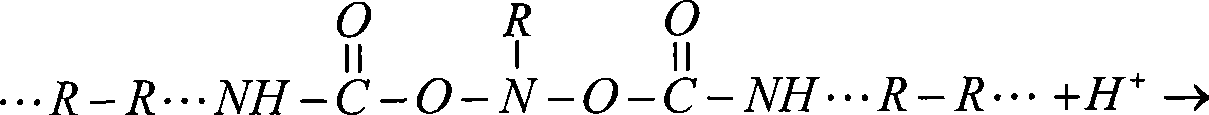

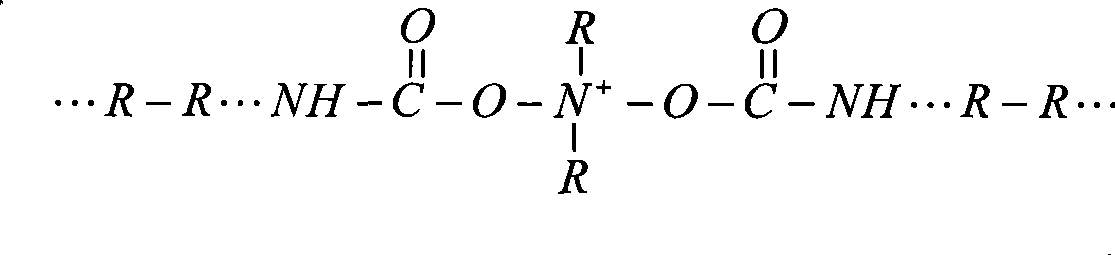

Method used

Image

Examples

Embodiment 1

[0040] Add 60% (accounting for solid mass) of polyester diol (CMA-1024), 5% (accounting for solid mass) polyethylene glycol and 35% (accounting for solid mass) toluene diisocyanate (TDI) to the belt in a certain proportion In a reactor with a stirring and reflux device, under the protection of high-purity nitrogen, a prepolymerization reaction is carried out to prepare a prepolymer. The reaction time is 0.5h, and the reaction temperature is 45°C. Raise the temperature to 60°C, add 1,4-butanediol, react for 2 hours, detect the NCO-content of the system, when the NCO-content reaches the theoretical value, cool down to 50°C, add 5% (accounting for monomer mass) amount of pro- Add the water chain extender MDEA within 1 hour, and the chain extension reaction takes 2 hours. Chain extension reaction until the NCO- content reaches the theoretical value. After cooling to 20°C, add glacial acetic acid to neutralize and dilute with acetone. After the viscosity is suitable, add water and ...

Embodiment 2

[0042] The preparation of prepolymer, chain extension reaction and neutralization and emulsification steps, are identical with embodiment 1, difference is, in prepolymer preparation, the ratio of the substance amount of polyester diol and Polyethylene Glycol is 10 : 1, prepolymerization reaction temperature is 50 ℃, and reaction time 0.5h, chain extension reaction, is identical with embodiment 1, and difference is, heating up temperature is 55 ℃, is cooled to 55 ℃, and addition consumption 8% (accounting for monomer quality ) of the hydrophilic chain extender MDEA.

Embodiment 3

[0044] Prepolymer preparation, chain extension reaction and neutralization and emulsification steps, embodiment 1 is the same, difference is, in prepolymer preparation, the ratio of the substance amount of polyester diol and polyethylene glycol is 9:1 , the prepolymerization reaction temperature is 55°C, the reaction time is 2h, the reaction is 2.5h, and the chain extension reaction is the same as in Example 1, the difference is that the heating temperature is 60°C, and the temperature is lowered to 50°C, and the addition amount is 8% (accounting for a unit body weight) of the hydrophilic chain extender MDEA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com