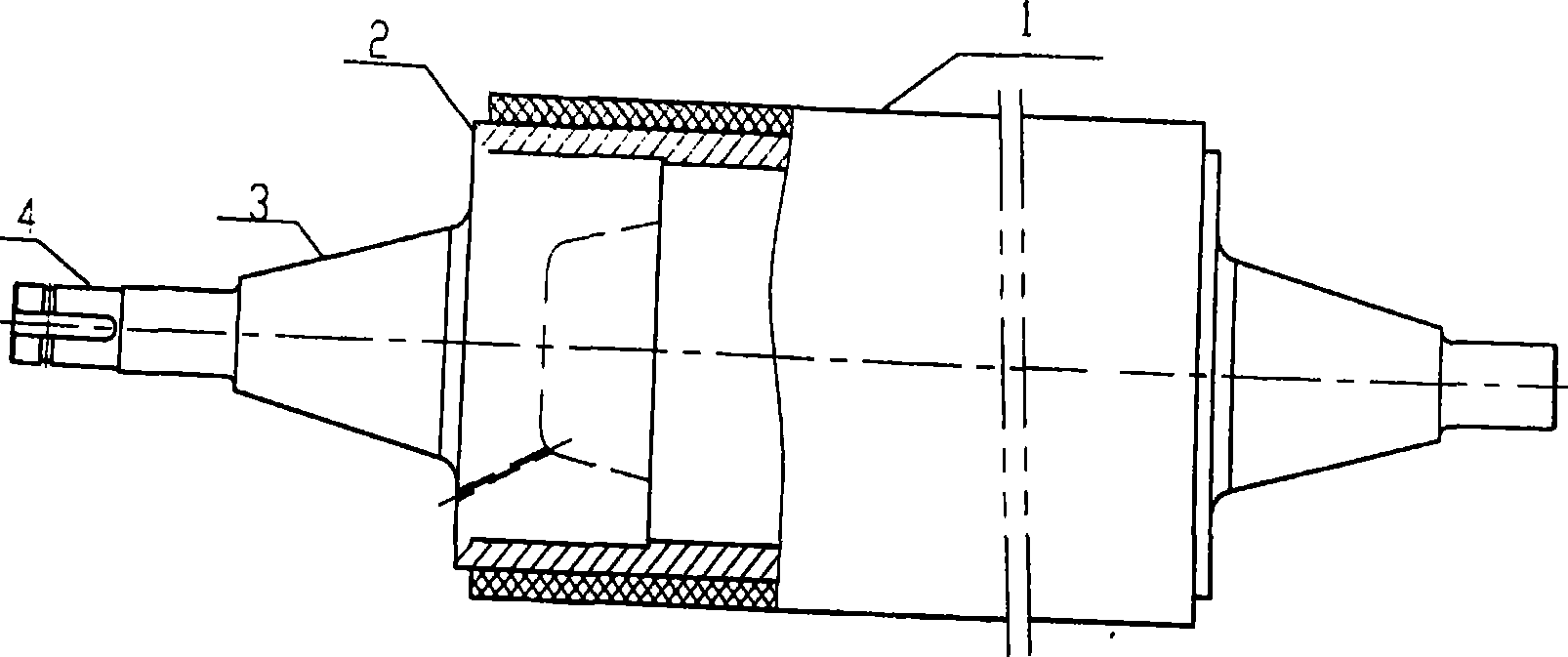

Polyurethane coating roller and manufacture method thereof

A technology of coating rollers and polyurethane, applied in the direction of household components, etc., to ensure the effect of repeated use and grinding, uniform mixing, and guaranteed pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

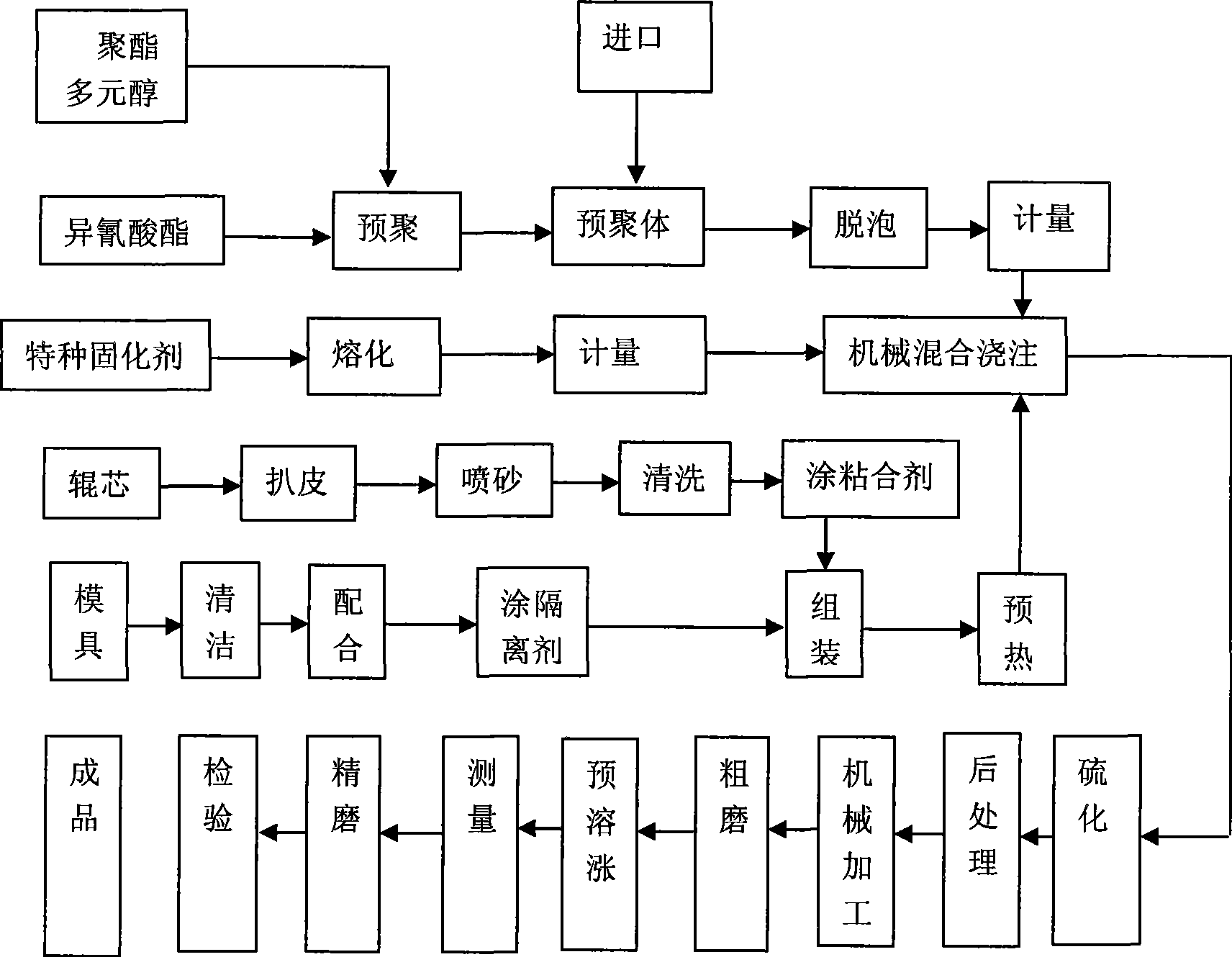

Method used

Image

Examples

Embodiment Construction

[0055] The following describes the present invention in more detail through the embodiments and in conjunction with the accompanying drawings.

[0056] 1. Main raw and auxiliary materials

[0058] Scientific name: polyethylene adipate propylene glycol ester

[0059] Appearance: white waxy solid or colorless transparent viscous liquid

[0060] Molecular weight: 1400~2000 (number average)

[0061] Moisture content: ≤0.02%

[0062] Hydroxyl value: 60~80(mgKOH / g)

[0063] Acid value: 1~3(mgKOH / g)

[0064] Addition amount is 60~60%.

[0065] B. Toluene diisocyanate (TDI) (Mitsui, Japan or BASF, USA)

[0066]Appearance: Colorless to light yellow transparent liquid

[0067] Purity: ≥98%

[0068] Hydrolyzed chlorine: 0.01~0.06%

[0069] Adding amount is 20-30%

[0070] C. Prepolymer: the model 218 product produced by Takeda Corporation of Japan, the addition amount is 7-10%.

[0071] D. Curing agent: Type II curing agent produced by Japan Takeda ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com