Nylon polymerization member water lubricating bearing for ship

A water-lubricated and marine-used technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as poor wear resistance and toughness, air bubbles in nylon castings, and high production costs, so as to improve performance and use Effects of life, enhanced hardness and toughness, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by way of examples.

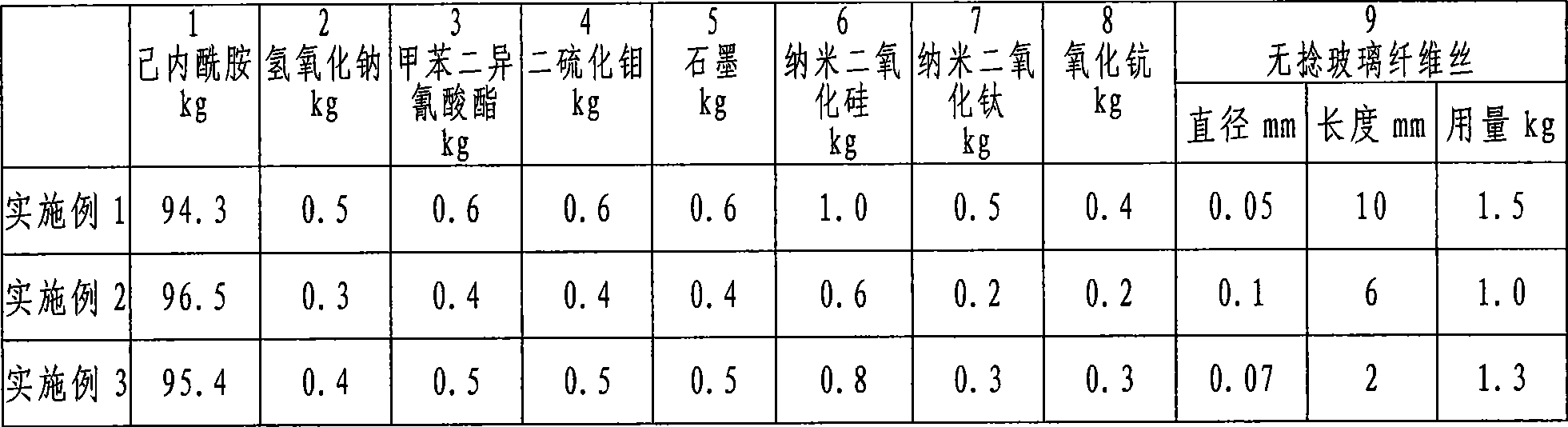

[0018] The consumption list of each component is as follows among the embodiment 1~3:

[0019]

[0020] The operation process of each embodiment is: take components 1, 4, 5, 6, 7, 8, and 9 and mix them thoroughly, put them into the head pot, heat and melt them, and when they reach 60°C, turn on the vacuum pump for suction filtration, and dehydrate under reduced pressure , stop vacuuming, open the vent hole of the second pot (the two pots are connected), when the pressure in the pot returns to atmospheric pressure, add component 2 to the first pot, continue vacuuming until the molten liquid is free of water and impurities, stop the vacuum pump and the heating furnace , open the top cover of the head pot, quickly put in component 3, after shaking, immediately pour the molten liquid into the mold preheated to 165°C, carry out centrifugal polymerization and casting, complete the polymerization in 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com