Low-hardness polyurethane rubber roll material and preparation method thereof

A technology of polyurethane glue and low hardness, which is applied in the field of organic polymer materials, can solve the problems of quality reduction, shortened life, poor wear resistance, etc., and achieve the effect of reducing carbon residue, long service life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

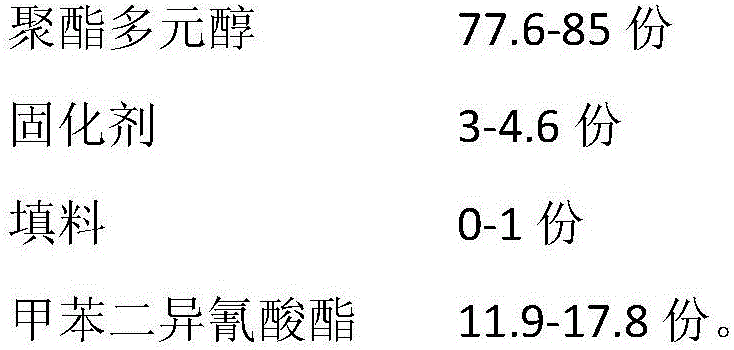

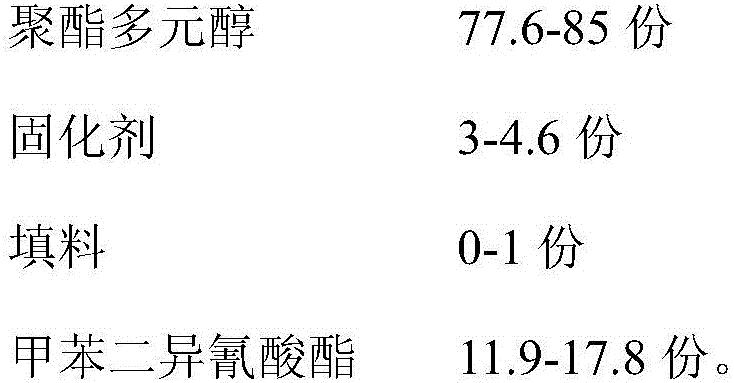

[0022] 85 parts of polyester polyol (adipic acid-ethylene glycol-1,4-butanediol system, hydroxyl value 45mgKOH / g, acid value 0.6mgKOH / g, molecular weight 2500), 3.1 parts of curing agent ( Triisopropanolamine: 1,4-butanediol = 6:4) was added into a reactor with a vacuum degassing device, stirred evenly, and dehydrated at 100°C for 2 hours until the moisture content was lower than 0.05%. Then lower the temperature to 70°C, add 11.9 parts of toluene diisocyanate, stir rapidly within 30 minutes, and de-foam at -0.09MPa under vacuum, inject into the pre-treated mold, and mature at 110°C for 48h.

[0023] The resulting elastomer had a hardness of 45A.

Embodiment 2

[0025] 82.5 parts of polyester polyol (adipic acid-ethylene glycol-1,2-propylene glycol system, hydroxyl value 56mg KOH / g, acid value 0.9mgKOH / g, molecular weight 2000), 3.0 parts of curing agent (trihydroxy Methyl propane: 1,4-butanediol = 6:4), 1 part of fumed silica was added to a reactor with a vacuum degassing device, stirred evenly, and dehydrated at 100°C for 2 hours until moisture Less than 0.05%. Then lower the temperature to 65°C, add 14.5 parts of toluene diisocyanate, stir rapidly within 20 minutes, and de-bubble at -0.1MPa under vacuum, inject it into the pre-treated mold, and mature at 100°C for 48h. The resulting elastomer had a hardness of 50A.

Embodiment 3

[0027] 80 parts of polyester polyol (adipic acid-ethylene glycol-1,2-propylene glycol system, hydroxyl value 62mgKOH / g, acid value 1.1mgKOH / g, molecular weight 1800), 4.0 parts of curing agent (three different Propanolamine: diisopropanolamine: trimethylolpropane = 1:1:1) into the reactor with a vacuum degassing device, stir evenly, and dehydrate at 110°C for 1 hour until the moisture content is low at 0.05%. Then lower the temperature to 60°C, add 16 parts of toluene diisocyanate, stir rapidly within 15 minutes, and de-foam at -0.1MPa under vacuum, inject it into the pre-treated mold, and mature at 120°C for 24 hours. The resulting elastomer had a hardness of 55A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com