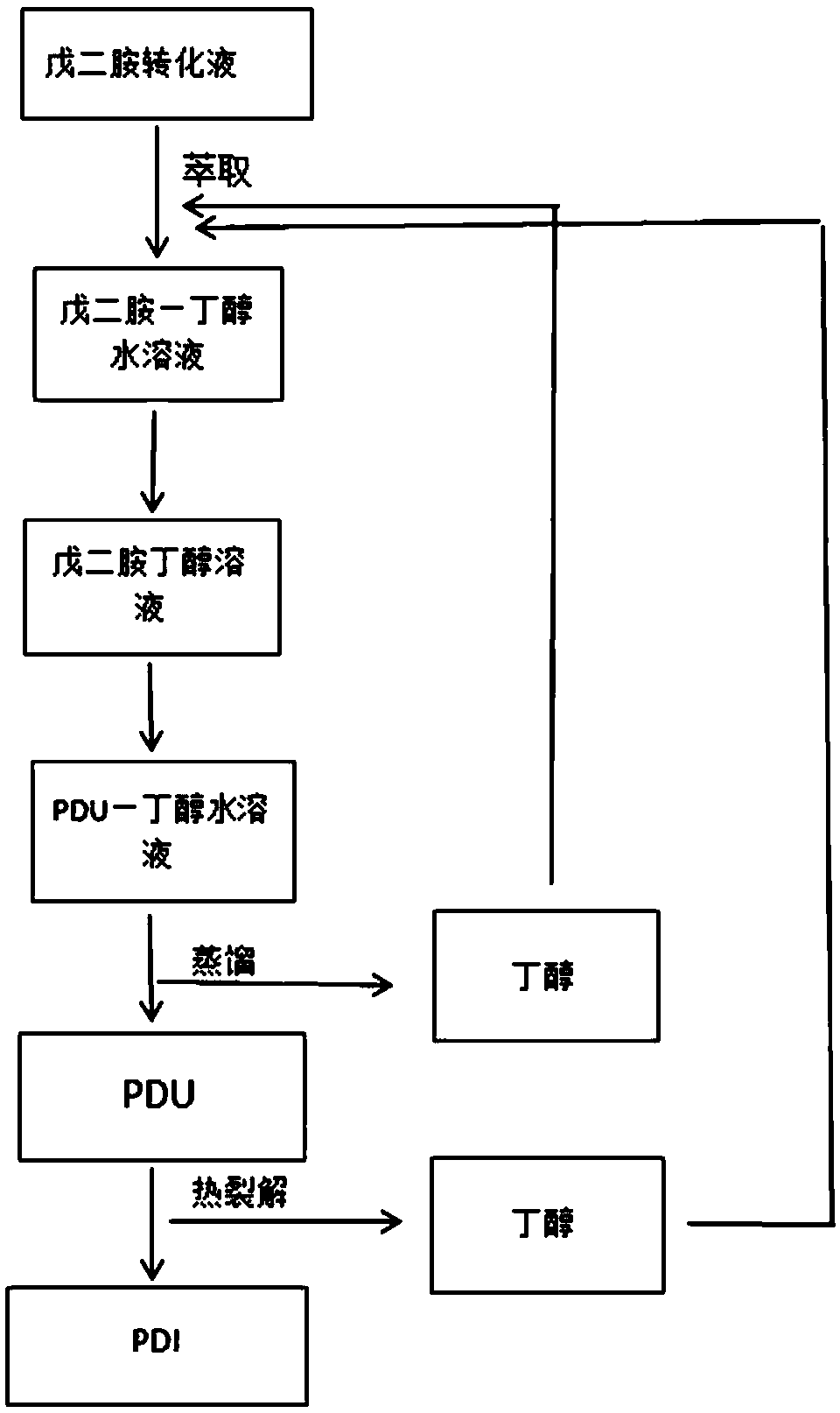

1, 5-pentyl diisocyanate preparation method

A technology of pentamethylene diisocyanate and butyl pentamethylene dicarbamate, which is applied in the field of preparation of 1,5-pentane diisocyanate to achieve the effects of reduced loss, high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

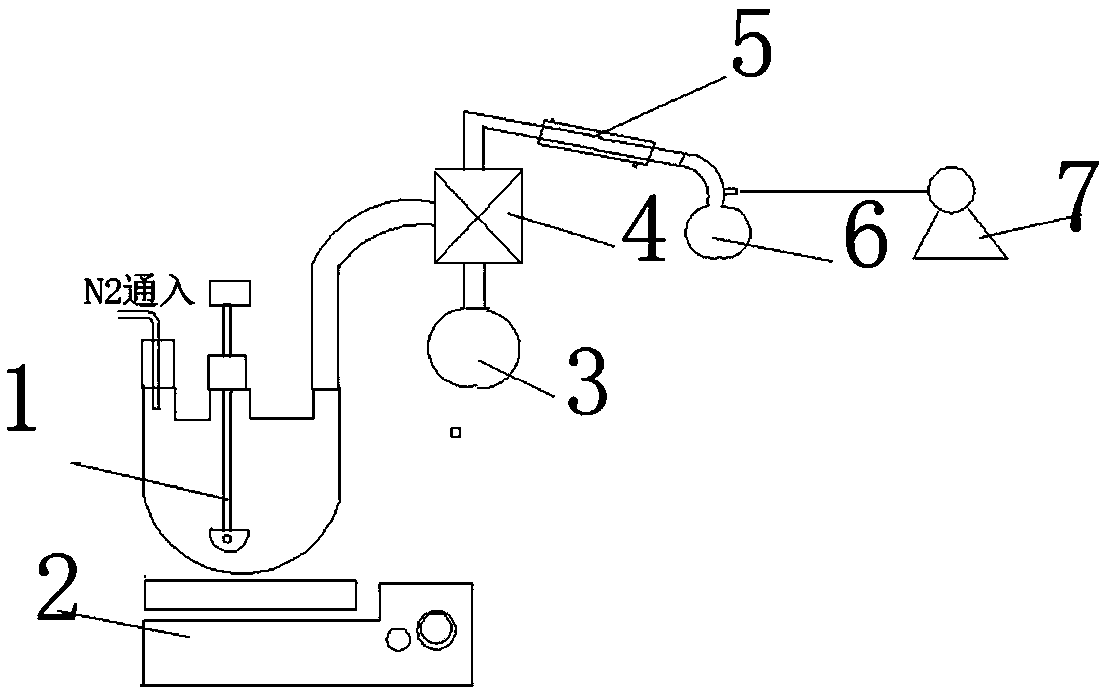

Method used

Image

Examples

Embodiment 1

[0022] (1) Lysine fermentation: firstly, transfer the lysine producing strain KA30 glycerol tube to the centrifuge tube for activation culture, then dilute the bacterial solution in the centrifuge tube and smear the plate (peptone 10g / L, yeast powder 5g / L L, sodium chloride 5g / L, agar powder 25g / L, sodium pyruvate 0.5g / L), select single bacterium colony, single bacterium colony is carried out shake flask fermentation verification. After verification, the lysine production strain was inserted into the shake flask for fermentation for 12h (sucrose 20g / L, magnesium sulfate 0.6g / L, potassium dihydrogen phosphate 0.6g / L, ammonium chloride 8.5g / L, yeast powder 6g / L , threonine 0.55g / L, methionine 0.1g / L, monosodium glutamate 7g / L, sodium pyruvate 0.55g / L), sodium hydroxide to adjust the pH to 7.0. Then insert the primary seed medium (consistent with the shake flask medium), control dissolved oxygen 30%-50%, cultivate for about 10h, stop cultivating when the total sugar content drops...

Embodiment 2

[0029] The preparation method is the same as in Example 1, except that the 1,5-pentanediamine n-butanol mixture (the molar ratio of 1,5-pentanediamine and n-butanol is 1:6) does not add n-butanol, urea and The molar ratio of 1,5-pentanediamine is 3:1, the molar ratio of catalyst to 1,5-pentanediamine is 0.5:100, the reaction temperature of carbamateization is 220°C, and the reaction time is 3h, to obtain Butyl pentamethylene dicarbamate (PDU) was 25.37g, the purity was 91.9%, the molar yield was 82.17%, and the molar recovery of n-butanol after vacuum distillation was 69%. The heat carrier selects naphthenic oil, weighs an appropriate amount of naphthenic oil and zinc acetate to make W (heat carrier): W (PDU)=20:1, W (catalyst): W (PDU)=1:100 (mass ratio), The thermal cracking reaction temperature is 270° C., the vacuum degree is set at 0.094 MPa, and the reaction time is 1 h. Finally, 7.98 g of the target product pentamethylene diisocyanate (PDI) was obtained, and the total ...

Embodiment 3

[0031] The preparation method is the same as in Example 1, except that an appropriate amount of n-butanol is added to make the molar ratio of 1,5-pentanediamine and n-butanol reach 1:7, and the molar ratio of urea and 1,5-pentanediamine is 5:1, the consumption and reaction conditions of other substances in the carbamate reaction system are the same as in Example 1, and 25.27g of pentamethylene dicarbamate (PDU) is obtained, the purity is 92.2%, and the molar yield is 82.11 %, n-butanol recovery rate is 73.1%. Heat carrier selects dibutyl phthalate, catalyzer selects zinc powder and zinc oxide, takes by weighing an amount of dioctyl phthalate and zinc powder, zinc oxide, makes W (heat carrier): W (PDU)=15: 1, W (catalyst): W (PDU)=5:100 (wherein the quality of zinc powder and zinc oxide respectively accounts for 50%), thermal cracking reaction reaction condition is the same as embodiment 1, and thermal cracking reaction finishes and finally obtains the target product Wuya Meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com