Recycling method for phosgene in tail gas generated in calorescence reaction for synthesizing normal-butyl isocyanate

A technology of n-butyl isocyanate and light reaction, which is applied in the field of resource recycling and environmental protection, can solve the problems of large pollution, large material loss, and high equipment investment, and achieve the effect of less equipment investment, less waste acid, and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

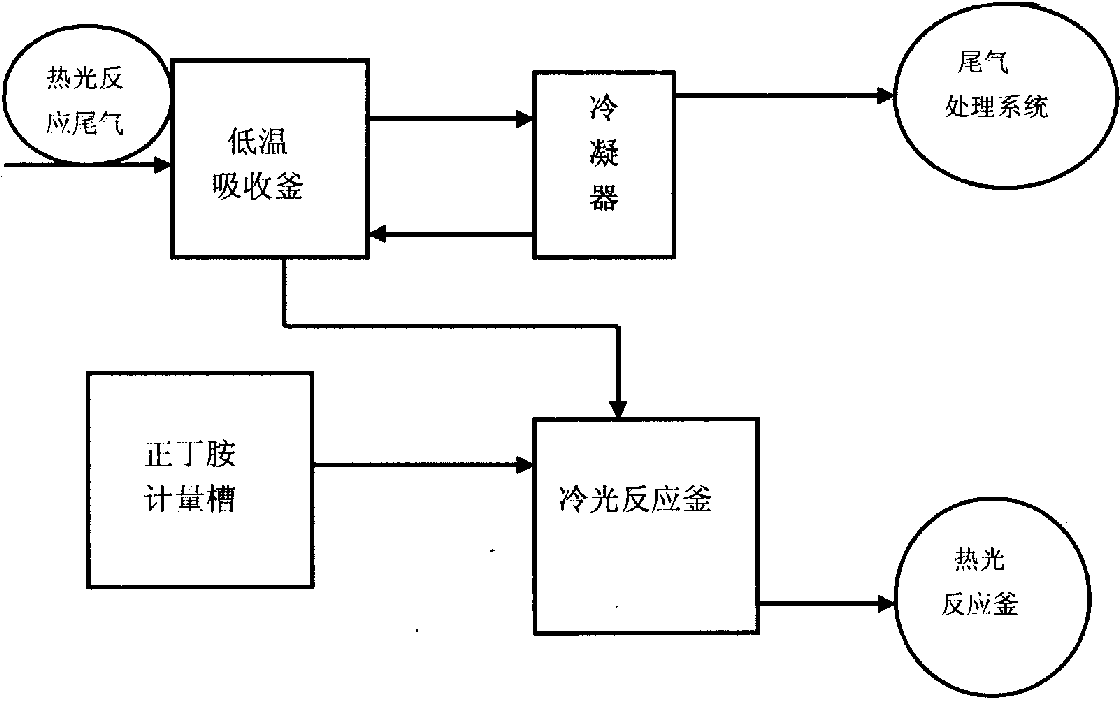

Image

Examples

Embodiment 1

[0028] The tail gas from the thermo-optic reaction of synthetic n-butyl isocyanate is continuously absorbed by a solvent at -8°C to -2°C, and then condensed by a condenser, and the uncondensed gas directly enters the tail gas treatment system. The solvent has been absorbed at low temperature for many times. When the concentration of phosgene in the solvent xylene reaches 45%, it is directly applied to the luminescence reaction. First, 3000L of the phosgene-containing solvent is transferred to the luminescence kettle, and n-butylene is added dropwise at -8°C to -2°C. Amine, when continuing to add n-butylamine dropwise, temperature drops significantly, reaches the amount of n-butylamine needed for reaction metering, stops dripping, keeps warm for 1 hour, obtains n-butylamyl chloride, and its content is 92.36% in analysis. Add n-butylamine acid chloride and solvent into thermo-optical reactor and n-butylamine hydrochloride to prepare n-butylisocyanate.

Embodiment 2

[0030] The tail gas from the thermo-optic reaction of synthetic n-butyl isocyanate is continuously absorbed by a solvent at -8°C to -2°C, and then condensed by a condenser, and the uncondensed gas directly enters the tail gas treatment system. The solvent has been absorbed at low temperature for many times. When the concentration of phosgene in the solvent xylene reaches 48%, it is directly applied to the luminescence reaction. First, 3000L of the light-containing solvent is transferred to the luminescence kettle, and n-butylamine is added dropwise at -10℃~-2℃. , when continuing to add n-butylamine dropwise, the temperature drops significantly until the amount of n-butylamine needed for reaction metering is reached, the dripping is stopped, and the insulation is kept for 1 hour to obtain n-butylamyl chloride, whose content is 93.56% in analysis. Add n-butylamine acid chloride and solvent into thermo-optical reactor and n-butylamine hydrochloride to prepare n-butylisocyanate.

Embodiment 3

[0032] The tail gas from the thermo-optic reaction of synthetic n-butyl isocyanate is continuously absorbed by a solvent at -8°C to -2°C, and then condensed by a condenser, and the uncondensed gas directly enters the tail gas treatment system. The solvent has been absorbed at low temperature for many times. When the concentration of phosgene in the solvent xylene reaches 50%, it is directly applied to the luminescence reaction. First, 3000L of the light-containing solvent is transferred to the luminescence kettle, and n-butylamine is added dropwise at -8°C to 0°C. When continuing to add n-butylamine dropwise, the temperature dropped significantly until the amount of n-butylamine needed for reaction metering was reached, then the dripping was stopped, and the temperature was kept for 1 hour to obtain n-butylamine acid chloride, whose content was analyzed to be 95.32%. Add n-butylamine acid chloride and solvent into thermo-optical reactor and n-butylamine hydrochloride to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com