Dye-sensitized solar cell and dye-sensitized solar cell module

A solar cell and dye-sensitized technology, which is applied in the field of dye-sensitized solar cells and dye-sensitized solar cell modules, can solve problems such as increased internal resistance, reduced short-circuit current, and reduced photoelectric conversion efficiency, and achieves high conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1-1

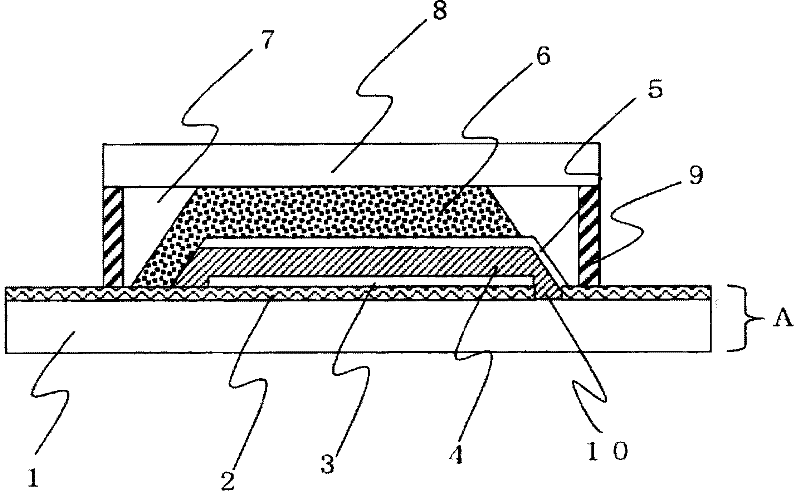

[0039] By laminating at least a catalyst layer, a porous insulating layer containing an electrolyte therein, and a porous semiconductor layer having adsorbed a sensitizing dye and containing an electrolyte therein on the first conductive layer in this order, and laminating the second conductive layer on the a structure formed between the porous insulating layer and the porous semiconductor layer (Embodiment 1-1 to be described below); and

[0040]By laminating at least a catalyst layer, a porous insulating layer containing an electrolyte therein, and a porous semiconductor layer adsorbed with a sensitizing dye and containing an electrolyte therein on the first conductive layer in this order, and further laminating the second conductive layer on the The structure formed on the above-mentioned porous semiconductor layer (Embodiment 2-1 to be described below).

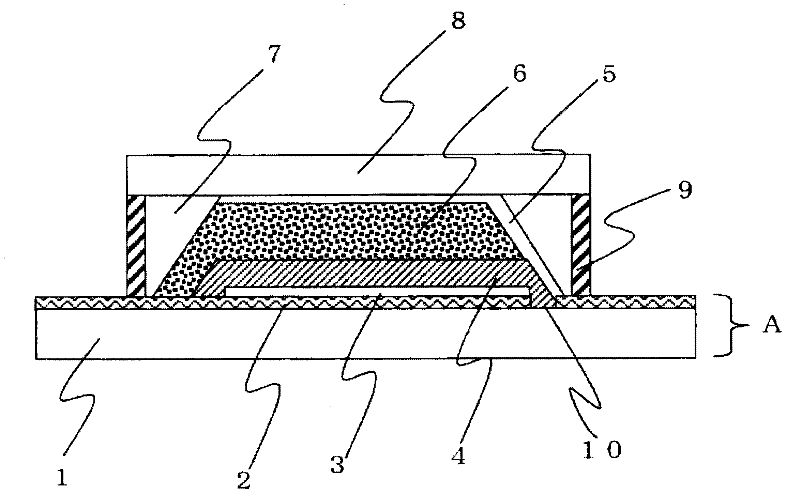

[0041] In addition, the solar cell of the present invention is characterized in that at least a porous semiconductor la...

Embodiment approach 3-1

[0043] By laminating a porous semiconductor layer having adsorbed at least a sensitizing dye and containing an electrolyte therein, a porous insulating layer containing an electrolyte therein, a second conductive layer, and a catalyst layer on a first conductive layer, and forming the porous insulating layer, a structure in which the second conductive layer and the catalyst layer are laminated in this order (Embodiment 3-1 to be described below); and

[0044] By laminating a porous semiconductor layer having adsorbed at least a sensitizing dye and containing an electrolyte therein, a porous insulating layer containing an electrolyte therein, a second conductive layer, and a catalyst layer on a first conductive layer, and forming the porous insulating layer, A structure in which the catalyst layer and the second conductive layer are stacked in this order (Embodiment 4-1 to be described below).

[0045] In the following, refer to Figure 1-4 and 6-9, embodiment 1-2 obtained by ...

Embodiment approach 1-2

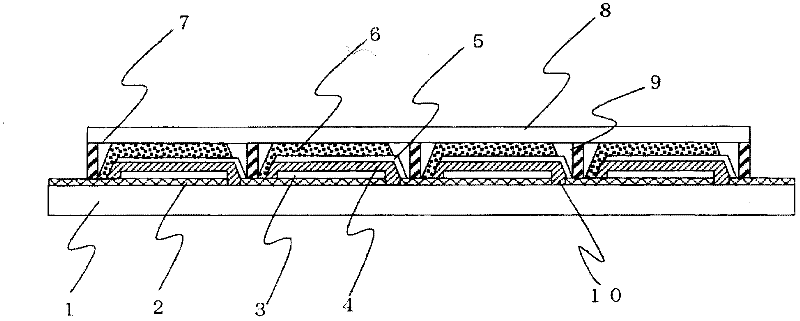

[0152] figure 2 is a schematic cross-sectional view showing the layer structure of main components of a solar cell module (Embodiment 1-2) obtained by electrically connecting a plurality of solar cells of the present invention (Embodiment 1-1) in series.

[0153] This solar cell module can be manufactured as follows.

[0154] First, the first conductive layer formed on the substrate 1 is patterned at prescribed intervals by a laser scribing method to form a plurality of scribe lines in which the conductive layer is removed. Accordingly, a plurality of first conductive layers 2 electrically isolated from each other are formed, and a solar cell formation region is provided on each first conductive layer 2 .

[0155] Among the plurality of first conductive layers 2, the first conductive layer 2 at one end in the direction perpendicular to the scribe line 10 is formed to have a smaller width, and no solar cell is formed on the first conductive layer 2 with the smaller width. on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com