Preparation method of super-hydrophobic super-oleophylic sponge

A super-lipophilic and super-hydrophobic technology is applied in the field of preparation of super-hydrophobic and super-oleophilic sponges, which can solve the problems of unpublished research on the lipophilic properties of coating materials and the inability to recycle them, achieve excellent separation ability, and reduce processing time. Process, the effect of good compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

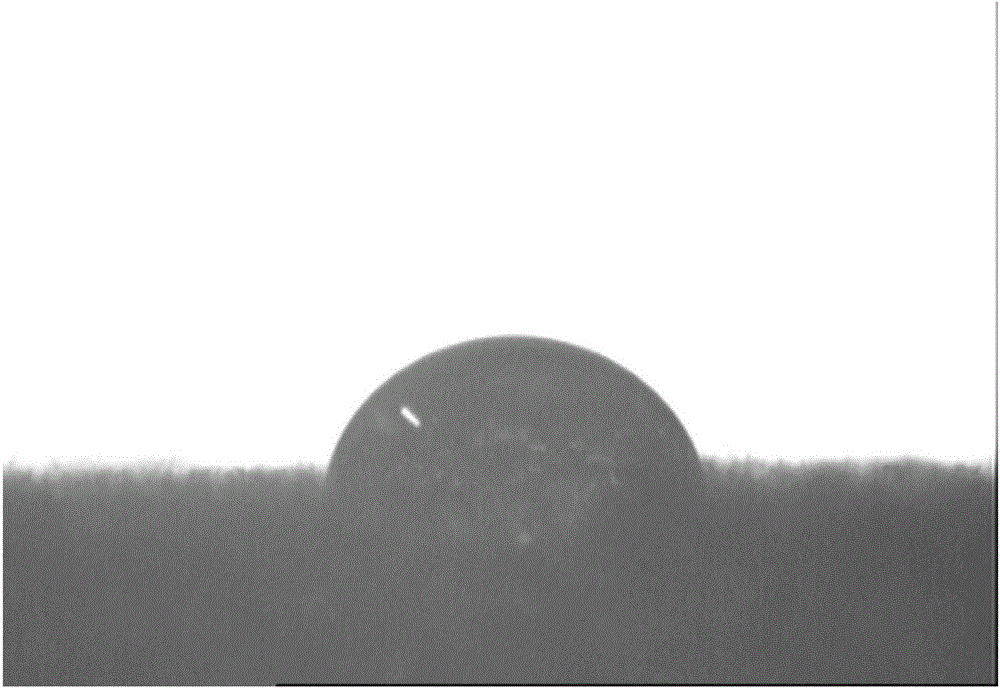

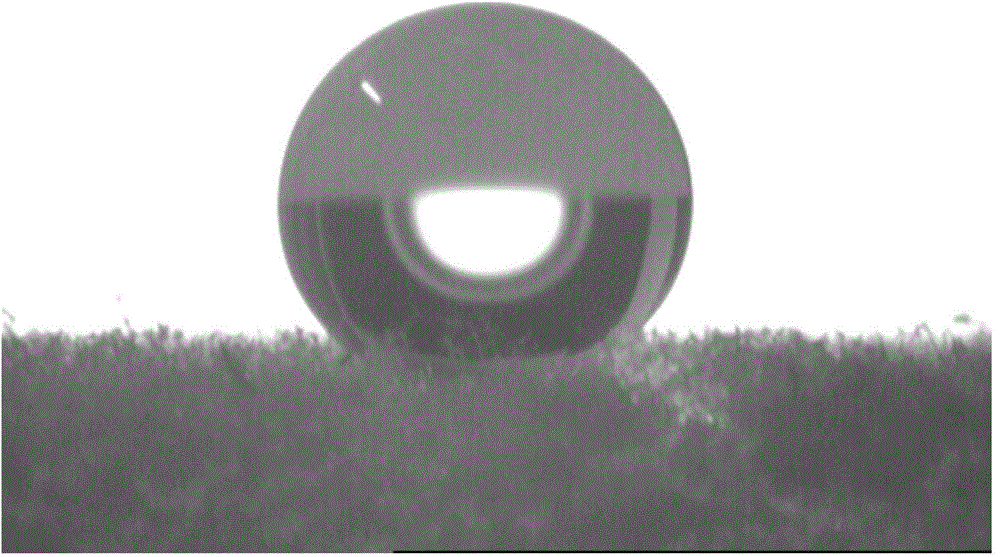

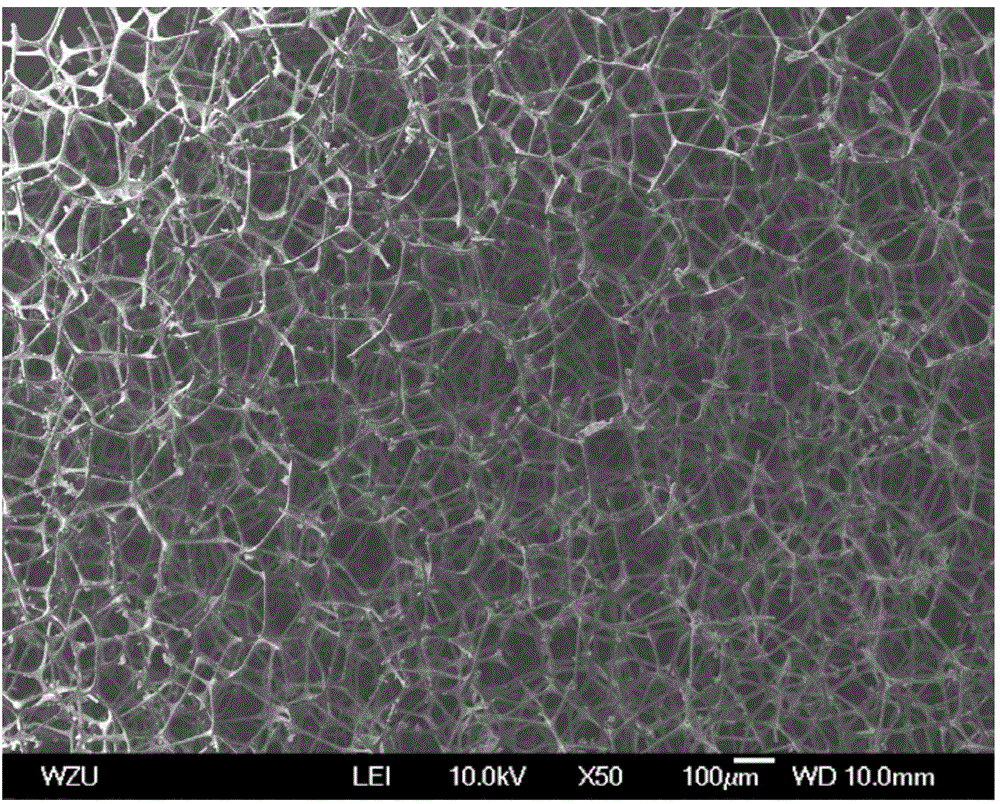

[0043] Add 0.5 g of 50 nanometer silicon dioxide to 50 ml of an ethanol solution of octaalkyltrichlorosilane (silane: ethanol = 1:100, mass ratio), ultrasonically disperse for 15 min, place in the refrigerator for 2 days, take it out and centrifuge, and use Rinse and wash with ethanol 3 times, obtain modified silica after drying, and place in a desiccator for later use. Set the density to 0.1kg / m 3 Put the polyester sponge into ethanol, ultrasonically clean it for 10 minutes, and place it in a 45-degree oven for heat treatment for 24 hours. Using ethanol as a solvent, configure 1 mg / mL modified silica solution A obtained above, and configure 2 wt% octadecyltriethoxysilane solution B. After immersing the polyester sponge in solution A for 3 seconds, take it out of a 45-degree oven and heat-treat it for 3 minutes, immerse it in solution B for 3 seconds, leave it at room temperature for 12 hours, and heat-treat it in a 45-degree oven for 24 hours. The water contact angle of the ...

Embodiment 2

[0045] Add 0.5 g of 50 nanometer silicon dioxide to 50 ml of an ethanol solution of octaalkyltrichlorosilane (silane: ethanol = 1:300, mass ratio), ultrasonically disperse for 15 min, place in the refrigerator for 2 days, take it out and centrifuge, and use Rinse and wash with ethanol 3 times, obtain modified silica after drying, and place in a desiccator for later use. Set the density to 0.3kg / m 3 Put the polyester sponge into ethanol, ultrasonically clean it for 10 minutes, and place it in a 45-degree oven for heat treatment for 24 hours. Using ethanol as a solvent, configure 1 mg / mL modified silica solution A obtained above, and configure 2 wt% octadecyltriethoxysilane solution B. After immersing the above sponge in solution A for 3 seconds, take it out of a 45-degree oven for heat treatment for 10 minutes, immerse it in solution B for 3 seconds, take it out, leave it at room temperature for 12 hours, and heat it in a 45-degree oven for 24 hours. The water contact angle of...

Embodiment 3

[0047] Add 0.5 g of 50 nanometer silicon dioxide to 50 ml of an ethanol solution of octaalkyltrichlorosilane (silane: ethanol = 1:500, mass ratio), ultrasonically disperse for 15 min, place in the refrigerator for 2 days, take it out and centrifuge, and use Rinse and wash with ethanol 3 times, obtain modified silica after drying, and place in a desiccator for later use. Set the density to 0.8kg / m 3 Put the polyester sponge into ethanol, ultrasonically clean it for 10 minutes, and place it in a 45-degree oven for heat treatment for 24 hours. Using ethanol as a solvent, configure 1 mg / mL L modified silica solution A, and configure 2 wt% octadecyltriethoxysilane solution B. After immersing the above-mentioned polyester sponge in solution A for 3 seconds, take it out of a 45-degree oven and heat-treat it for 5 minutes, immerse it in solution B for 3 seconds, take it out, leave it at room temperature for 12 hours, and heat-treat it in a 45-degree oven for 24 hours. About 92 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com