High-efficiency and energy-saving potassium titanate whisker preparation method

A potassium titanate whisker, high-efficiency and energy-saving technology, applied in the field of material chemistry, can solve problems such as waste of energy, low production efficiency, harsh preparation conditions, etc., to achieve improved energy utilization, excellent thermal insulation performance, and complete crystal structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

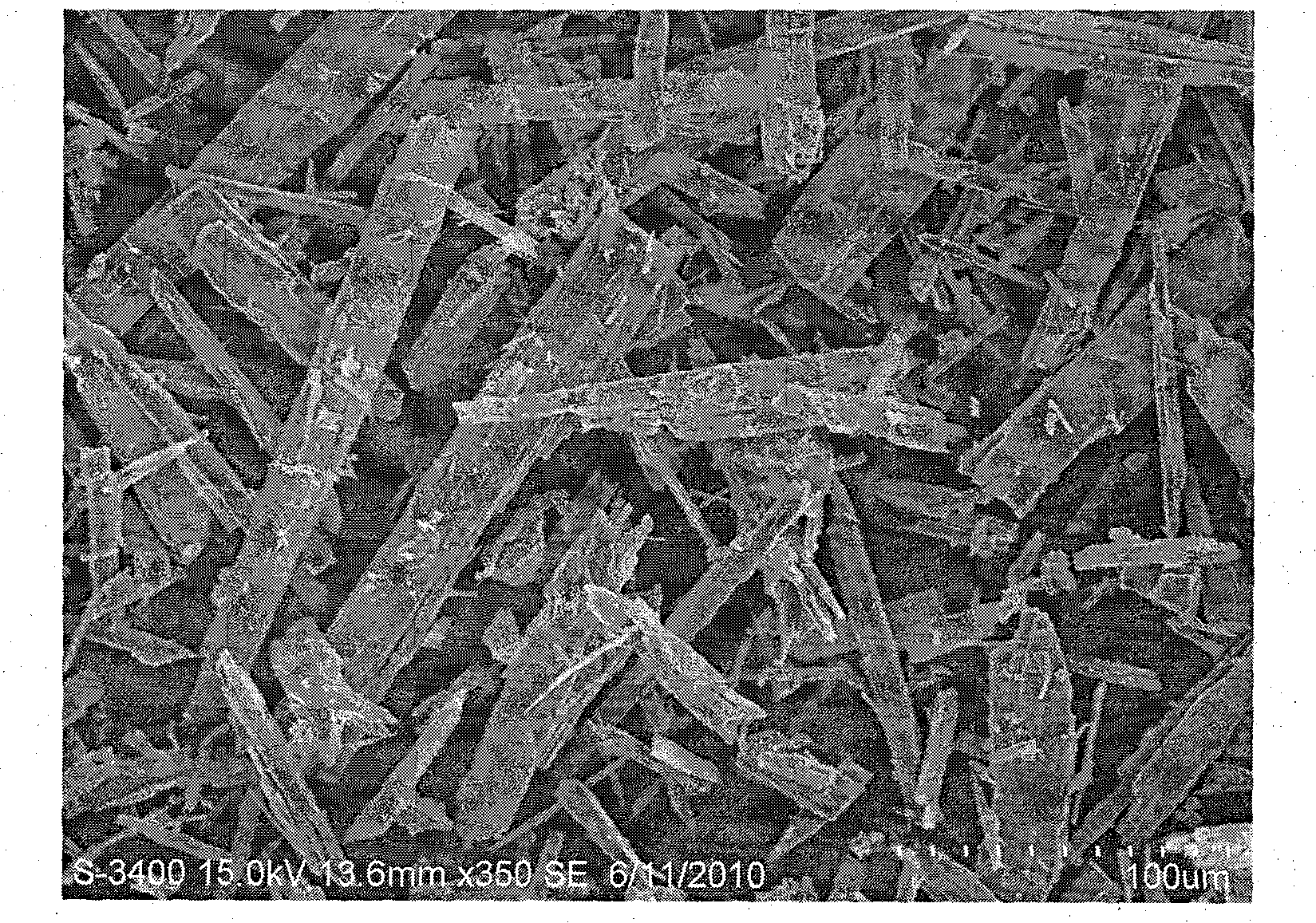

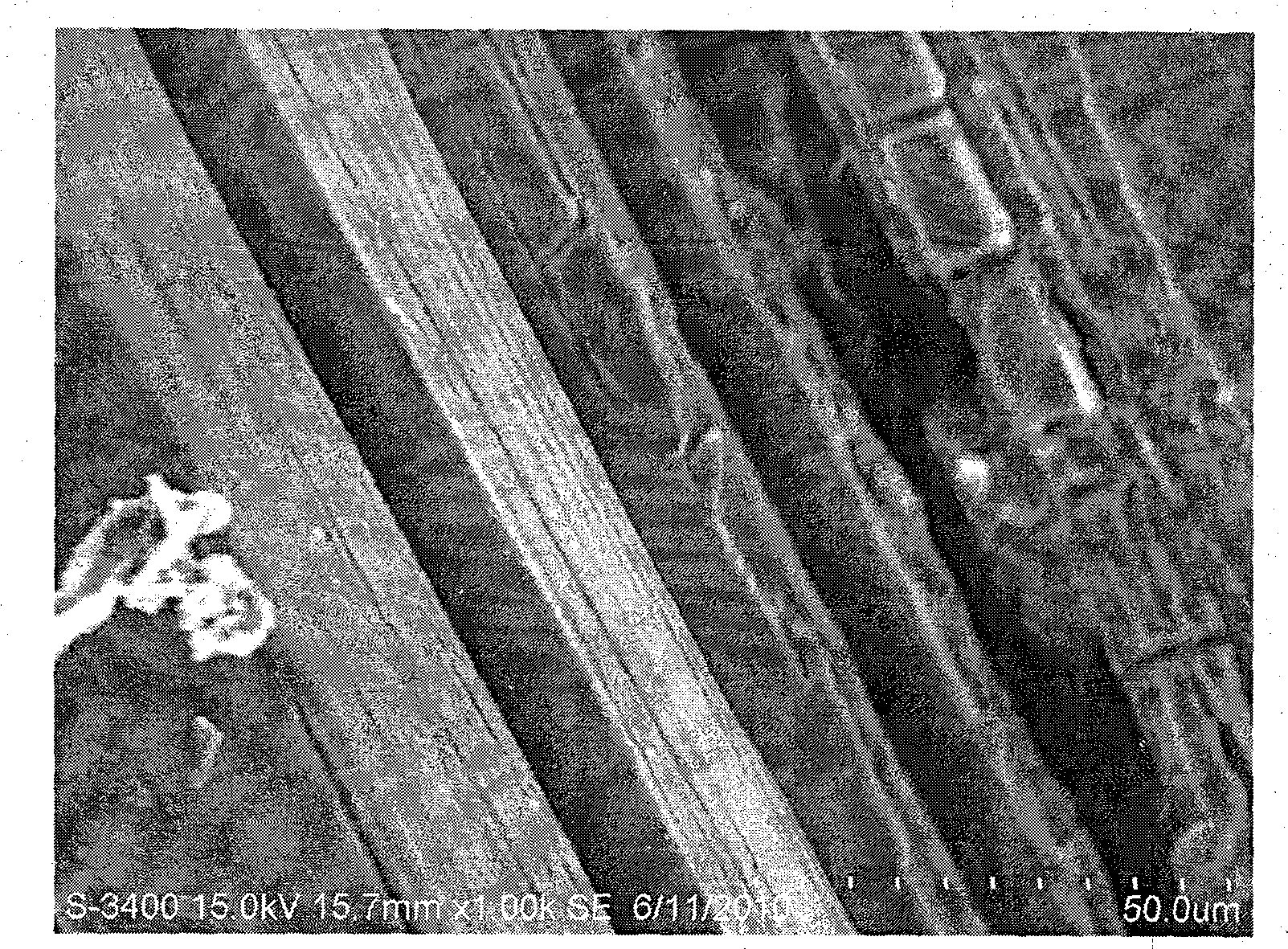

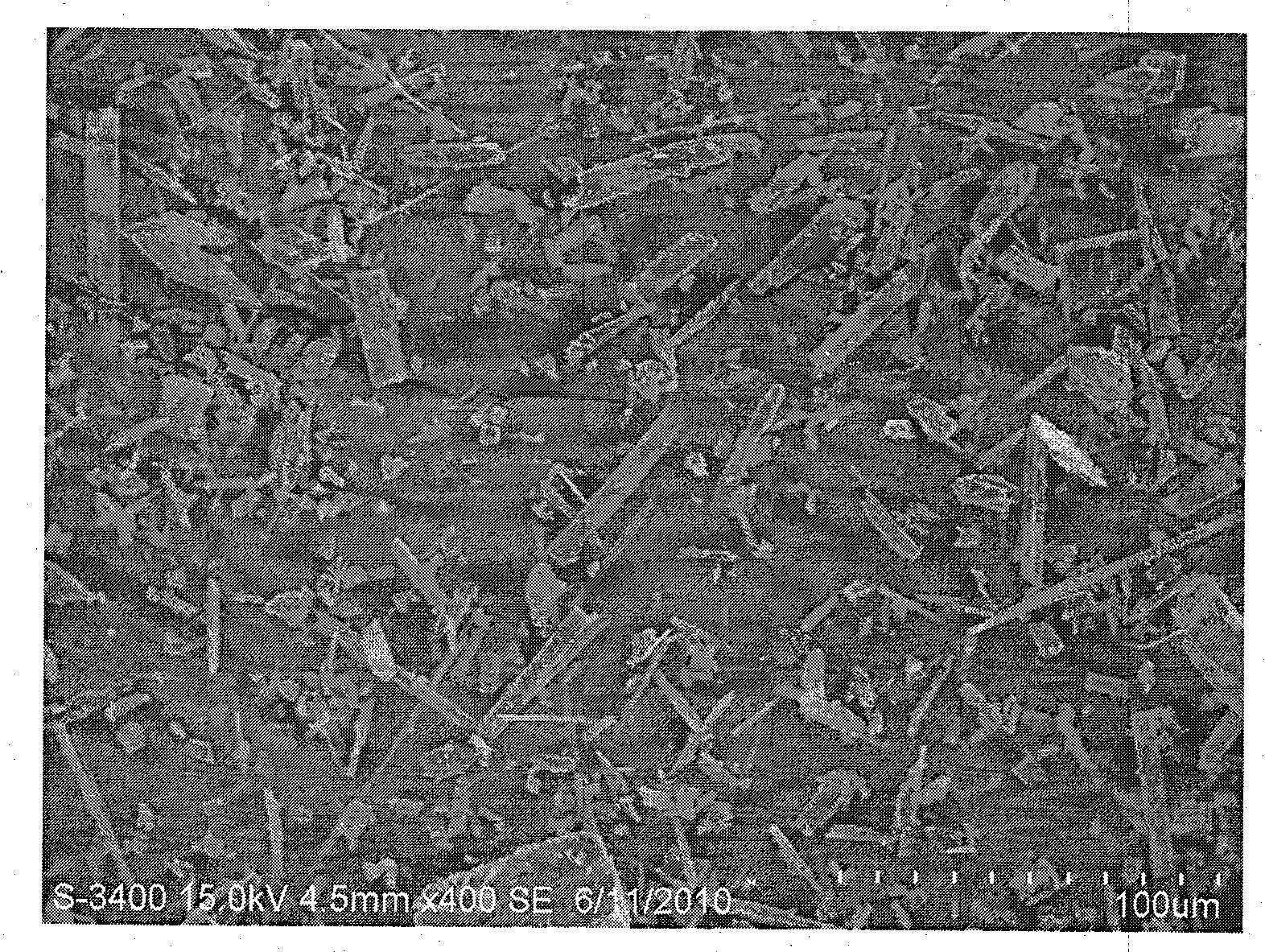

Image

Examples

Embodiment 1

[0028] Weigh titanium source titanium dioxide and potassium source potassium oxide in a molar ratio of 1:1, mechanically grind the system until the system is uniform, and obtain the precursor required for the preparation of whiskers; place the above precursor in a crucible at 35°C, preheat The time is 5 hours; the preheated precursor is put into a continuous rotary calcination kiln for calcination, the temperature is 800°C, and the calcination time is 5 hours; The potassium dititanate is obtained by moisture absorption and deweaving in the kiln for 24 hours; the potassium dititanate is neutralized by a quantitative pickling device to complete the quantitative conversion of potassium ions and filtered to obtain titanium with different compositions. Potassium titanate whiskers; the obtained potassium titanate whiskers are subjected to high-temperature shaping treatment in a shaping kiln, the temperature of the shaping kiln is 500° C., and the shaping time is 5 hours. The pure wh...

Embodiment 2

[0030] Titanium source metatitanic acid and potassium source potassium hydroxide are weighed according to the ratio of the molar ratio of titanium to potassium atoms of 1:6, mechanically ground until the system is uniform, and the precursor required for preparing whiskers is obtained; the above precursor is placed in In the crucible at 500°C, the preheating time is 0.1 hour; put the preheated precursor into a continuous rotary calciner for calcination at a temperature of 1300°C, and the calcination time is 0.5 hour; The time for hygroscopic deweaving is 2 hours, the humidity is 70%, and the temperature is 400°C. After the calcined product is crushed by machine, it is placed in a constant temperature and constant humidity moisture absorption hydrolysis kiln for hygroscopic hydrolysis treatment to obtain potassium dititanate; the potassium dititanate is neutralized by a quantitative pickling device to complete the quantitative determination of potassium ions Transform, filter an...

Embodiment 3

[0032] Weigh titanium source titanium dioxide and potassium source potassium carbonate in a molar ratio of 1:4, mechanically grind until the system is uniform, and obtain the precursor required for the preparation of whiskers; place the above precursor in a crucible at 300°C, preheat The time is 3 hours; the preheated precursor is put into a continuous rotary calcination kiln for calcination, the temperature is 800°C, and the calcination time is 5 hours; after high-temperature sintering, after high-temperature calcination, machine crushing, moisture absorption and dewoven The time is 4 hours, the humidity is 90%, and the temperature is 300°C. After the calcined product is crushed by machine, it is placed in a constant temperature and constant humidity moisture absorption hydrolysis kiln for hygroscopic hydrolysis treatment to obtain potassium dititanate; the potassium dititanate is neutralized by a quantitative pickling device to complete the quantitative determination of potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com