Porous carbon coated ZnO nanometer composite material and preparing method thereof

A nanocomposite material, porous carbon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of rapid combination of photogenerated electrons and holes, hindering photocatalytic efficiency, etc. Achieve the effects of excellent photodegradation catalytic performance, uniform particle size, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

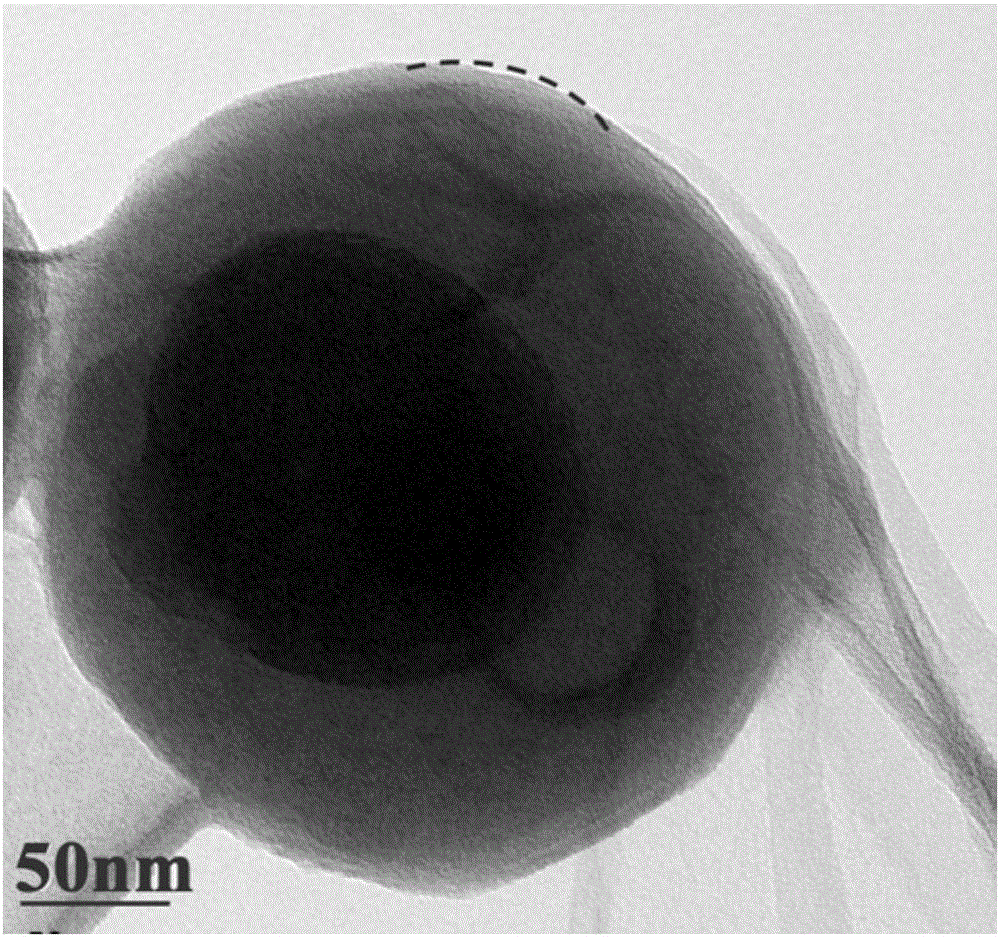

[0025] Weigh ZnO nanoparticles (0.325g, 4mmol), 2-methylimidazole (0.328g, 4mmol) was added to the autoclave with polytetrafluoroethylene liner, then add 32mL mixed solvent (mixed by DMF and water, V DMF :V 水 =3:1), after ultrasonication for 30min, place it in a constant temperature oven at 90°C for 48h of heat preservation reaction, after the reaction is completed, naturally cool to room temperature, take out the reaction kettle, separate the precipitate by centrifugation, and separate the precipitate with absolute ethanol and deionized Washed with water several times and dried to obtain a solid product, labeled as ZIF-8@ZnO, the above ZIF-8@ZnO was heated in a tube furnace under N 2 Calcined under the atmosphere, during the calcination process, the heating rate was increased to 500°C at a rate of 5°C / min, and the reaction was kept at this temperature for 3 hours. After calcination, a black solid powder was obtained, which was washed with deionized water, centrifuged, and dr...

Embodiment 2

[0027] Weighed ZnO nanoparticles (0.325g, 4mmol), 2-methylimidazole (0.492g, 6mmol) was added to an autoclave with a polytetrafluoroethylene liner, followed by adding 40mL of DMF and water mixed solvent (V DMF :V 水 =1:1)), after ultrasonication for 20min, put it in a constant temperature oven at 150°C for 10h of heat preservation reaction, after the end of the reaction, naturally cool to room temperature, take out the reaction kettle, separate the precipitate by centrifugation, and use absolute ethanol and deionized water respectively After repeated washing and drying, a solid product was obtained, which was labeled as ZIF-8@ZnO. The above ZIF-8@ZnO was heated in a tube furnace under N 2 Calcined under the atmosphere, during the calcination process, the heating rate was raised to 700 ℃ at a rate of 5 ℃ / min, and the reaction was kept at this temperature for 2 hours. After calcination, a black solid powder was obtained, which was washed with deionized water, centrifuged, and dri...

Embodiment 3

[0029] Weigh ZnO nanoparticles (0.325g, 4mmol), and 2-methylimidazole (0.984g, 12mmol) is added to an autoclave with a polytetrafluoroethylene liner; then add 60mL of DMF and water mixed solvent (V DMF :V 水 =2:1), after ultrasonication for 30min, placed in a constant temperature oven at 130°C for 24h heat preservation reaction; after the reaction, it was naturally cooled to room temperature to take out the reactor, centrifuged to separate the precipitate, and washed with absolute ethanol and deionized water for several times Washed and dried to obtain a solid product, labeled as ZIF-8@ZnO, the above ZIF-8@ZnO was heated in a tube furnace under N 2 Calcined under the atmosphere, during the calcination process, the heating rate was raised to 900 °C at a rate of 5 °C / min, and the reaction was kept at this temperature for 1 hour. After calcination, a black solid powder was obtained, which was washed with deionized water, centrifuged, and dried to obtain the obtained product. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com