Flue gas desulfurization process

A process method and flue gas technology, applied in the field of ionic liquid solution, can solve the problems of slow mass transfer and high viscosity of ionic liquid, and achieve the effects of saving water resources, improving transportation and dispersing performance, and low cost of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

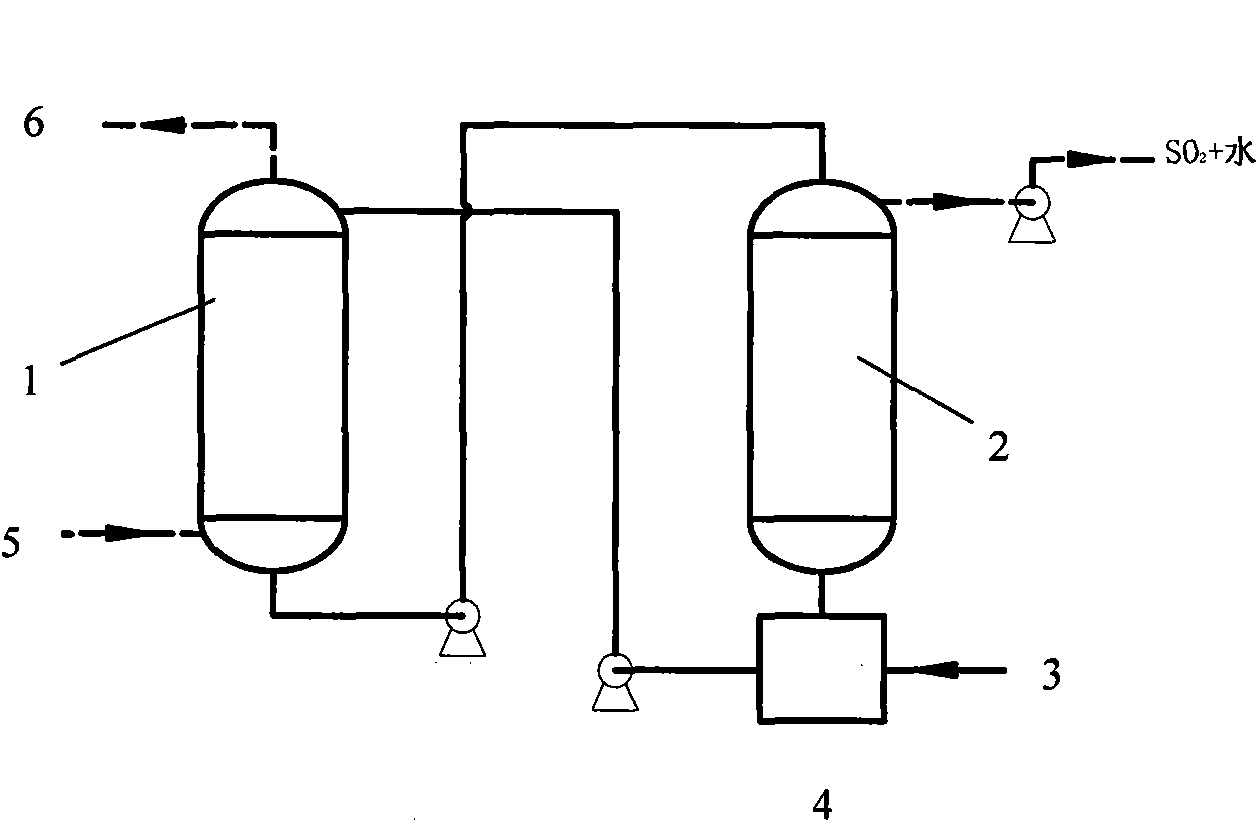

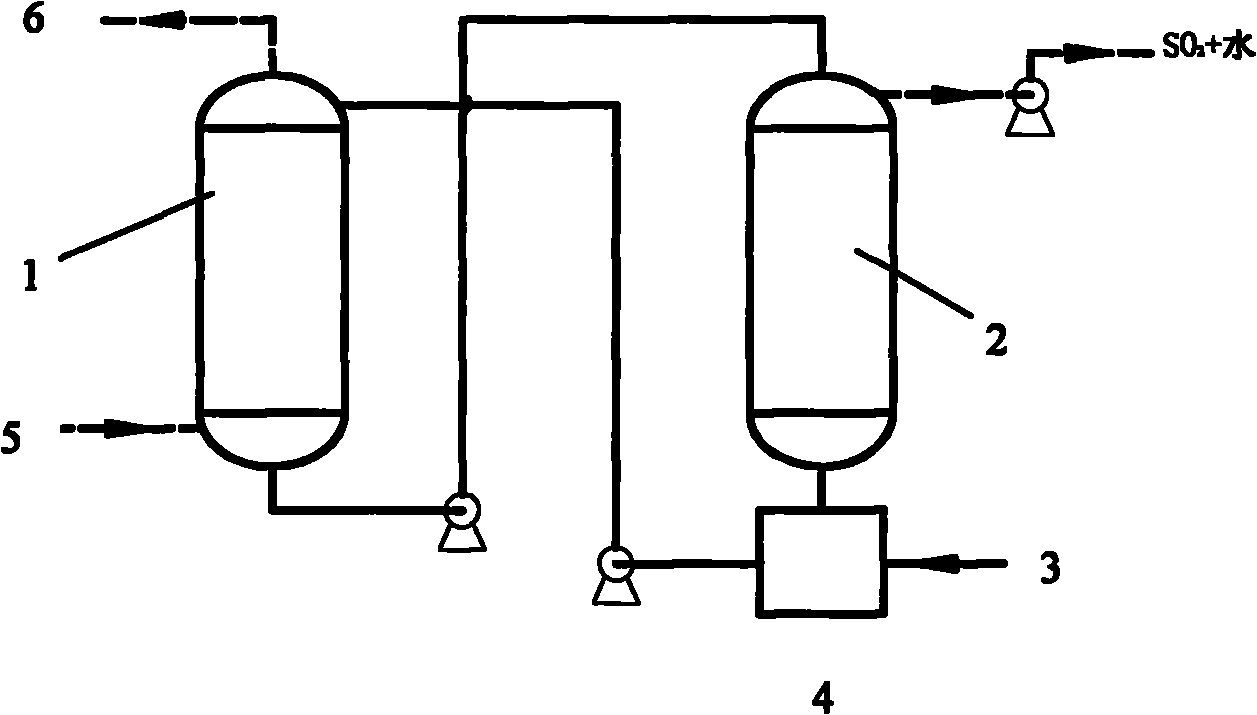

Image

Examples

Embodiment 1

[0037] This example illustrates that the tetramethylguanidine lactate ionic liquid solution is used as the absorbent, and the packed tower is used as the absorption tower to absorb SO in the flue gas at 60°C and 0.1MPa. 2 craft.

[0038] Tetramethylguanidine lactate was formulated into an aqueous solution with a mass fraction of 50%. The flue gas from the coal-fired boiler, after dust removal treatment, the flue gas temperature is 150°C, SO 2 The content is 2150mg / m 3 , cooled to 60°C, and sent to the absorption tower, the pressure in the absorption tower is 0.1MPa. The ratio of the amount of ionic liquid solution to the flue gas flow rate is 1:1000 (V / V), and the absorption tower is a packed tower with Raschig rings as fillers. The upper part of the absorption tower is a liquid inlet pipe with a liquid distribution device, and the lower part is an air inlet with a gas distribution device. Tail gas enters the absorption tower from the bottom air inlet and contacts with the...

Embodiment 2

[0040] This example shows that the ethanolamine lactate ionic liquid solution is used as the absorbent, and the conventional plate tower is used as the absorption tower to absorb SO in the flue gas at 60°C and 1.0MPa. 2 craft.

[0041] The ethanolamine lactate was formulated into an aqueous solution with a mass fraction of 90%. The tail gas from the boiler, after dust removal treatment, SO 2 The content is 2150mg / m 3 , cooling down to 60°C. In order to improve the absorption effect, the flue gas is boosted to 1.0MPa and sent into the absorption tower, and the pressure inside the absorption tower is 1.0MPa. The ratio of the amount of ionic liquid to the volume of flue gas flow is 1:60, and the absorption tower is a plate tower. The upper part of the absorption tower is a liquid inlet pipe with a liquid distribution device, and the lower part is an air inlet with a gas distribution device. The tail gas enters the absorption tower from the air inlet and contacts with the ion...

Embodiment 3

[0043] This example illustrates the use of 1-(1-aminopropyl)-3-methylimidazolium hexafluorophosphate ionic liquid solution as the absorbent, and the spray tower as the absorption tower to absorb flue gas at 70°C and 5.0MPa Medium SO 2 craft.

[0044] 1-(1-aminopropyl)-3-methylimidazolium hexafluorophosphate was formulated into an aqueous solution with a mass fraction of 95%. The tail gas from the boiler, after dust removal treatment, has a flue gas temperature of 150°C, SO 2 The content is 2150mg / m 3 , cooled to 70°C, pressurized and sent into the absorption tower, the pressure inside the absorption tower is 5.0MPa. The ratio of the amount of ionic liquid to the volume of the flue gas flow is 1:10. The absorption tower is a spray tower. The upper part of the absorption tower is a liquid inlet pipe, and the lower part is an air inlet with a gas distribution device. The tail gas enters the absorption tower from the air inlet and contacts with the ionic liquid solution for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com