Method for degrading organic wastewater by hydroxylamine hydrochloride reinforced iron oxide activated persulfate

A technology for activating persulfate and iron oxides, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. and other problems, to achieve the effect of reducing cost, low cost and improving degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for hydroxylamine hydrochloride to strengthen iron oxides to activate persulfate to degrade organic waste water, comprising the following steps:

[0033] Put 1L of simulated wastewater containing 0.1mmol / L Orange G (sodium 1-phenylazo-2-naphthol-6,8-disulfonate) into the reactor, add 0.5mmol hydroxylamine hydrochloride, and adjust the pH to 3. Add 0.5g ferric oxide and 1mmol potassium persulfate to it, and react at room temperature for 30min.

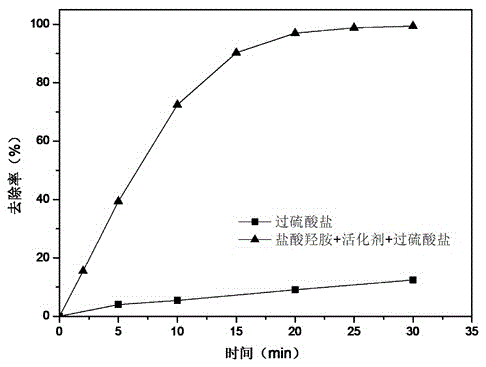

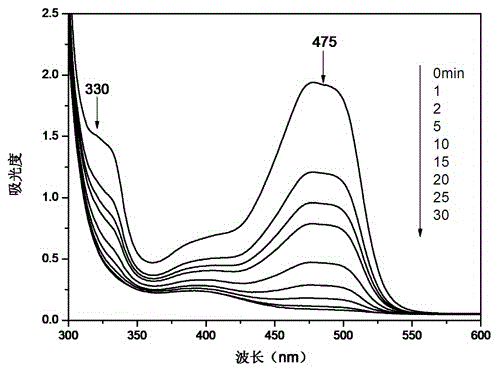

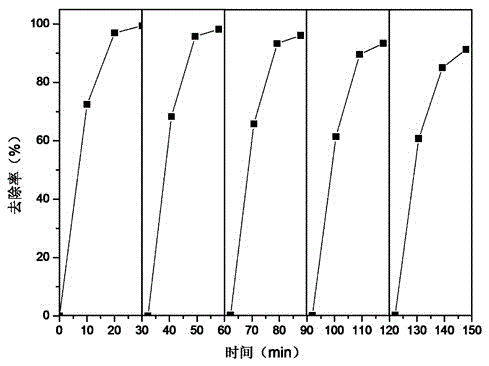

[0034] figure 1 Represented in is the time-removal rate curve graph that only adds persulfate to degrade organic wastewater and utilizes the hydroxylamine hydrochloride of embodiment 1, activator ferric oxide and persulfate to degrade organic wastewater. Depend on figure 1 It can be seen that the removal rate of only adding persulfate oxidation is only about 10% at 30 min, while the removal rate of hydroxylamine hydrochloride-enhanced iron oxide activated persulfate oxidation can be as high as 99%. It shows that the h...

Embodiment 2

[0038] A method for hydroxylamine hydrochloride to strengthen iron oxides to activate persulfate to degrade organic waste water, comprising the following steps:

[0039] Put 1L of simulated wastewater containing orange G (the initial concentration of orange G is 0.1mmol / L) in the reactor, add 0.5mmol of hydroxylamine hydrochloride, adjust the pH to 3, and then add 0.5g of iron sludge and 1mmol of persulfate Potassium hydrogen, reacted at room temperature for 30min.

[0040] Depend on Figure 4 It can be seen that the oxidation rate of hydroxylamine hydrochloride-enhanced iron oxide-activated persulfate system is much higher than that of only iron oxide-activated persulfate system. The degradation rate of orange G activated by iron oxide persulfate oxidation is only about 37% in 30 minutes, but the present invention can reach more than 99% in 10 minutes after strengthening with hydroxylamine hydrochloride.

Embodiment 3

[0042] A method for hydroxylamine hydrochloride to strengthen iron oxides to activate persulfate to degrade organic waste water, comprising the following steps:

[0043] Put 1L of simulated wastewater containing orange G (the initial concentration of orange G is 0.1mmol / L) in the reactor, add 0.5mmol of hydroxylamine hydrochloride, adjust the pH to 3, and then add 0.5g of ferric oxide and 1mmol Potassium hydrogen persulfate was reacted at room temperature for 30 minutes. It is measured that the removal rate of orange G of the present invention can reach 71% in 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com