Device for treating chlorophenol wastewater by ultrasonic-assisted active membrane electrode and treatment method

An ultrasonic-assisted, active membrane technology, applied in the direction of special treatment targets, water/sewage treatment, chemical instruments and methods, etc., to reduce osmotic resistance, accelerate electrochemical reaction rate, and restore the effect of electrode membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

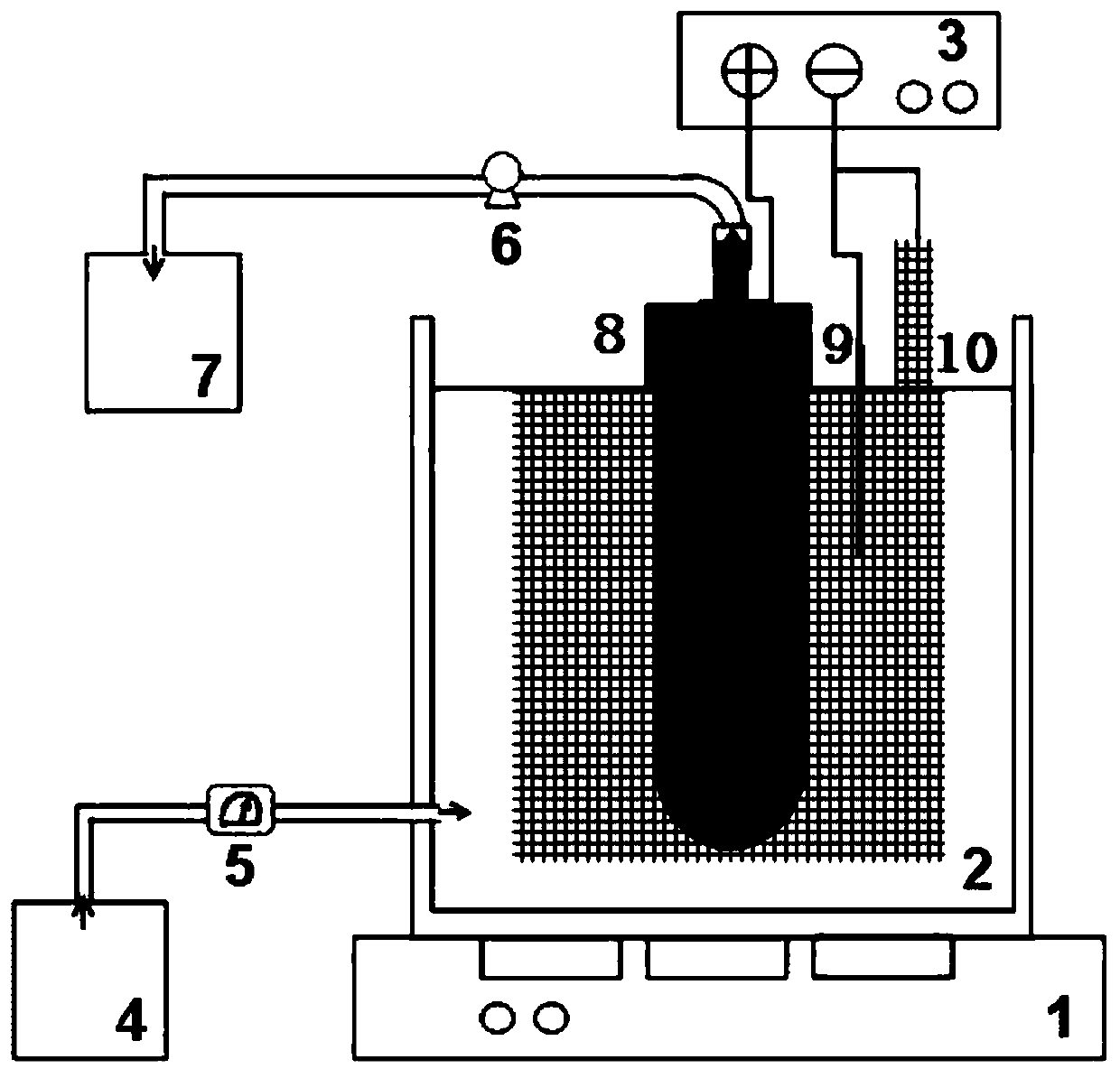

Method used

Image

Examples

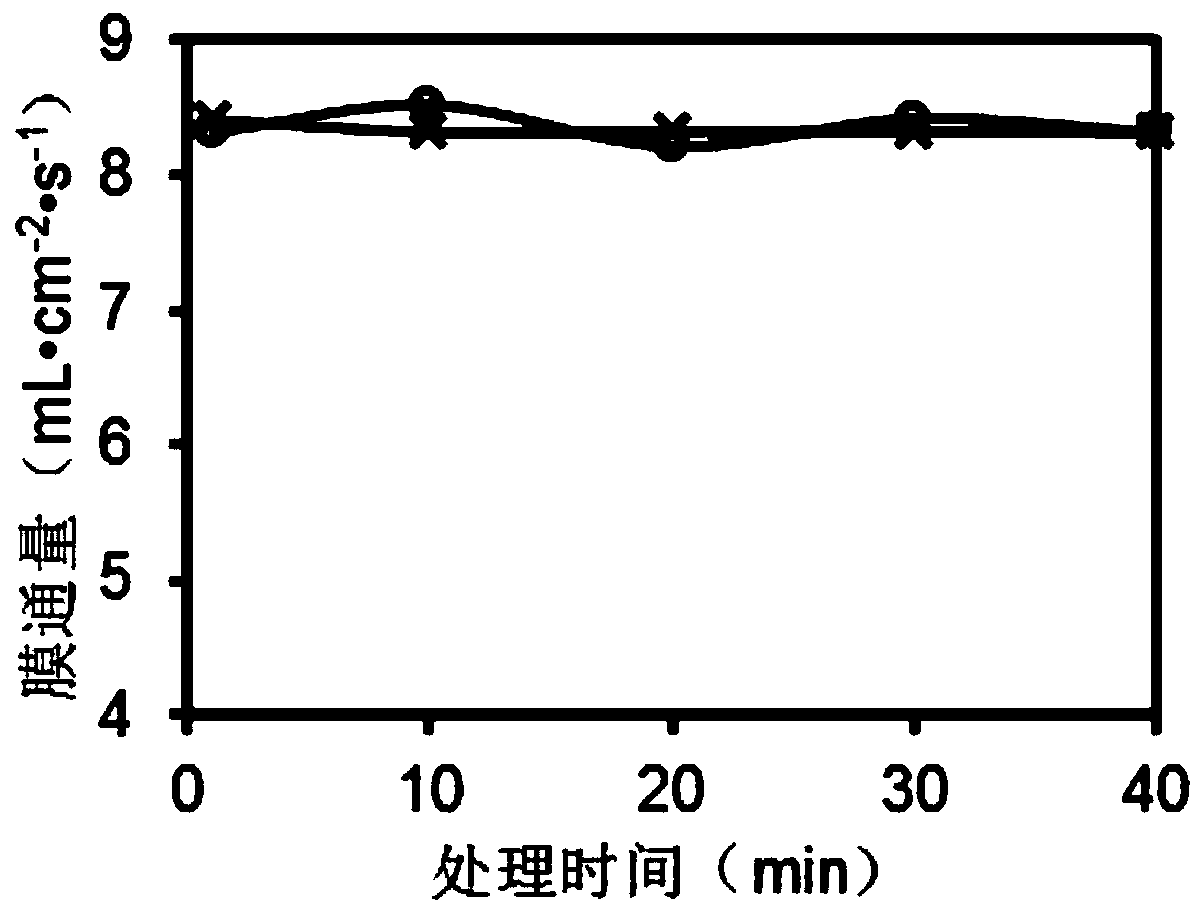

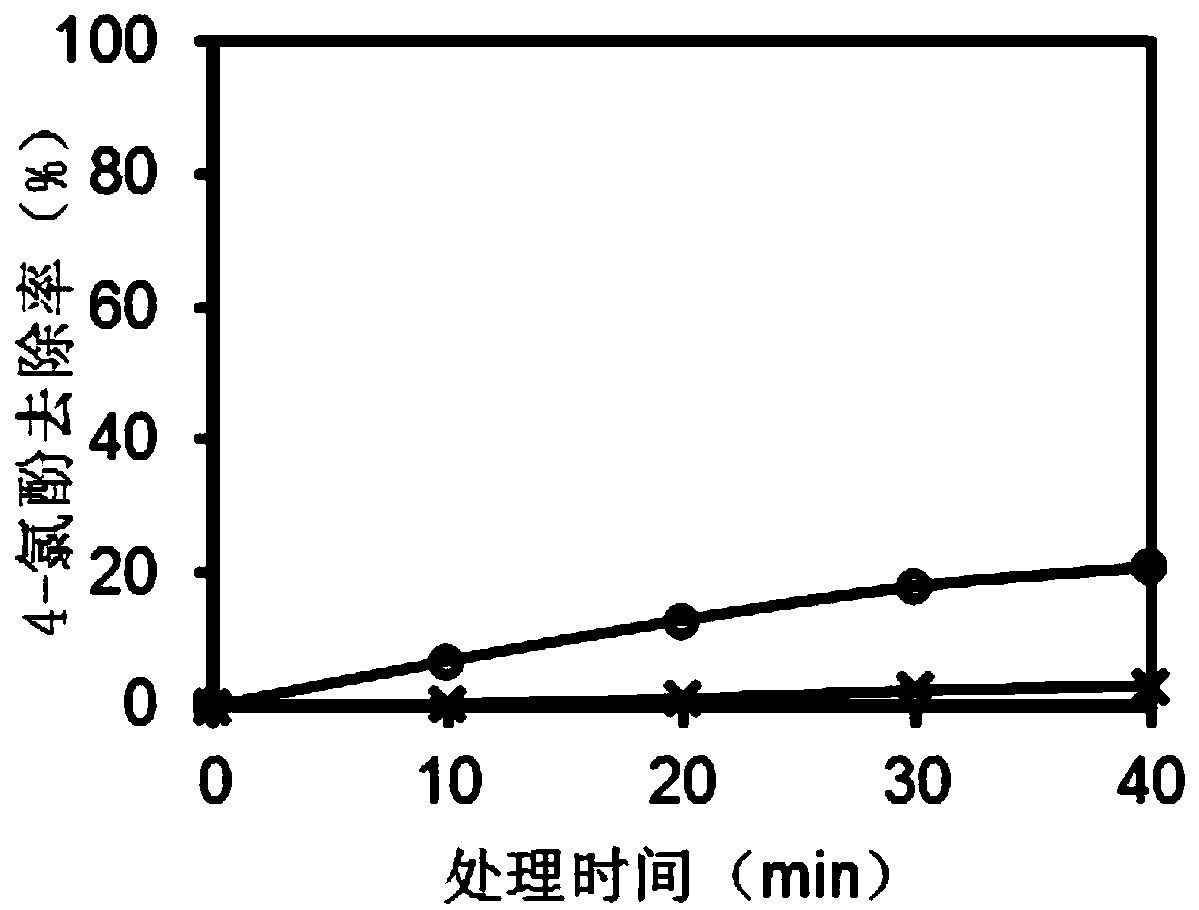

Embodiment 1

[0039] Experimental group: configuration containing 4-chlorophenol concentration of 50mg L -1 Simulated waste water was treated in the device of the present invention for 40 minutes. The specific operating parameters and processing effects are as follows: the ultrasonic input power is 80W, and the ultrasonic frequency is 25kHz. The operating voltage of the regulated power supply is 1V, and the current density is 0.85mA cm -2 . In order to improve the conductivity, the sewage treatment tank contains an inert electrolyte Na 2 SO 4 , whose concentration is 0.05mol L -1 . The anode material chooses conductive ceramic material titanium suboxide active film electrode (length 7.7cm, inner diameter 2.3cm, length 2.8cm), the cathode material chooses stainless steel mesh (length 55cm, height 7.5cm, wire diameter 1mm, aperture 2.63mm), and the reference Electrode selection Ag / AgCl electrode (0.195V vs SHE). The wire material is copper wire. The anode is located in the center of t...

Embodiment 2

[0042] Experimental group: configuration containing 4-chlorophenol concentration of 50mg L -1 Simulated waste water was treated in the device of the present invention for 40 minutes. The specific operating parameters and processing effects are as follows: the ultrasonic input power is 80W, and the ultrasonic frequency is 25kHz. The operating voltage of the regulated power supply is 3V, and the current density is 0.85mA cm -2 . In order to improve the conductivity, the sewage treatment tank contains an inert electrolyte Na 2 SO 4 , whose concentration is 0.05mol L -1 . The anode material chooses conductive ceramic material titanium suboxide active film electrode (length 7.7cm, inner diameter 2.3cm, length 2.8cm), the cathode material chooses stainless steel mesh (length 55cm, height 7.5cm, wire diameter 1mm, aperture 2.63mm), and the reference Electrode selection Ag / AgCl electrode (0.195V vs SHE). The wire material is copper wire. The anode is located in the center of t...

Embodiment 3

[0045] Experimental group: configuration containing 4-chlorophenol concentration of 50mg L -1 Simulated waste water was treated in the device of the present invention for 40 minutes. The specific operating parameters and processing effects are as follows: the ultrasonic input power is 80W, and the ultrasonic frequency is 25kHz. The operating voltage of the regulated power supply is 6V, and the current density is 0.85mA cm -2 . In order to improve the conductivity, the sewage treatment tank contains an inert electrolyte Na 2 SO 4 , whose concentration is 0.05mol L -1 . The anode material chooses conductive ceramic material titanium suboxide active film electrode (length 7.7cm, inner diameter 2.3cm, length 2.8cm), the cathode material chooses stainless steel mesh (length 55cm, height 7.5cm, wire diameter 1mm, aperture 2.63mm), and the reference Electrode selection Ag / AgCl electrode (0.195V vs SHE). The wire material is copper wire. The anode is located in the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com