A method for degrading printing and dyeing wastewater by anthraquinones

A technology for printing and dyeing wastewater and anthraquinone, which is applied in chemical instruments and methods, textile industry wastewater treatment, special compound water treatment, etc., can solve problems such as increased hydrogen peroxide concentration, high operating costs, and ozone instability, and achieves The effect of simple process flow, avoiding secondary pollution, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for degrading printing and dyeing wastewater by anthraquinones, which specifically includes the following steps:

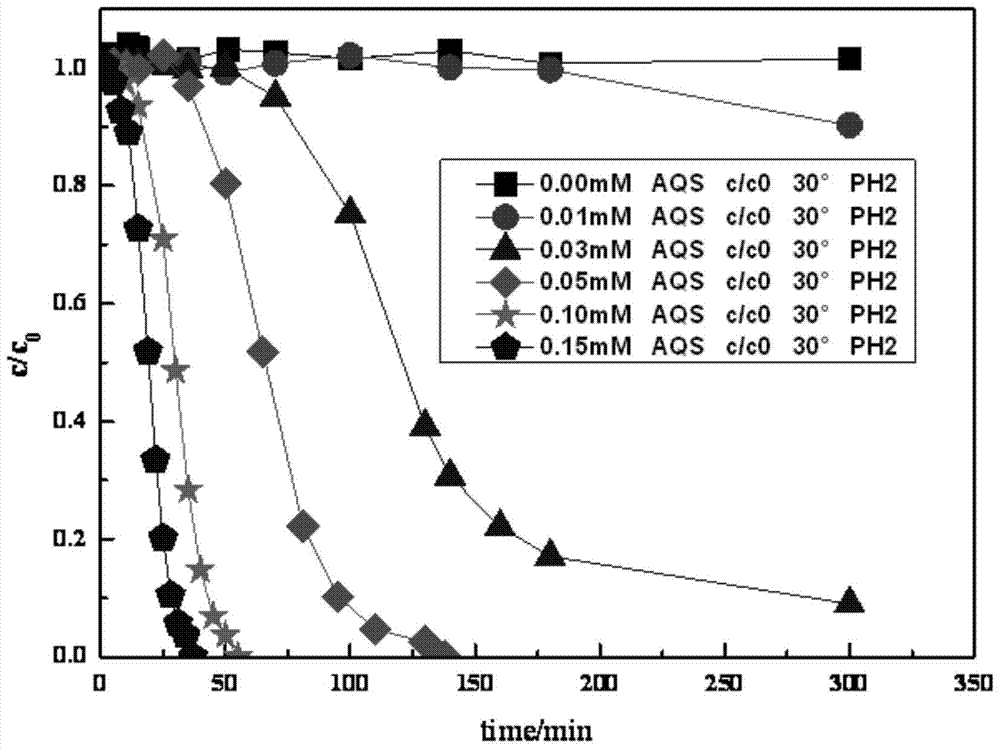

[0032] Step 1, in the rhodamine B printing and dyeing wastewater of 0.02mmol / L, add 2-sodium anthraquinone sulfonate (AQS), the concentration of 2-sodium anthraquinone sulfonate (AQS) in wastewater is respectively 0mmol / L, 0.01 mmol / L, 0.03mmol / L, 0.05mmol / L, 0.10mmol / L and 0.15mmol / L, and adjust the pH value to 2 with dilute sulfuric acid;

[0033] Step 2: Stir with a mechanical electronic stirrer, keep the rotation speed constant, the temperature is 30° C., and the reaction time is 300 min. detected figure 1 The data:

[0034] figure 1 is the degradation characteristics of Rhodamine B by AQS under different concentration conditions, from figure 1 It can be seen that when the concentration of AQS is 0mmol / L, 0.01mmol / L, 0.03mmol / L, 0.05mmol / L, 0.10mmol / L and 0.15mmol / L, the degradation rate of Rhodamine B is 0, 10 %, ...

Embodiment 2

[0036] This embodiment provides a method for degrading printing and dyeing wastewater by anthraquinones, which specifically includes the following steps:

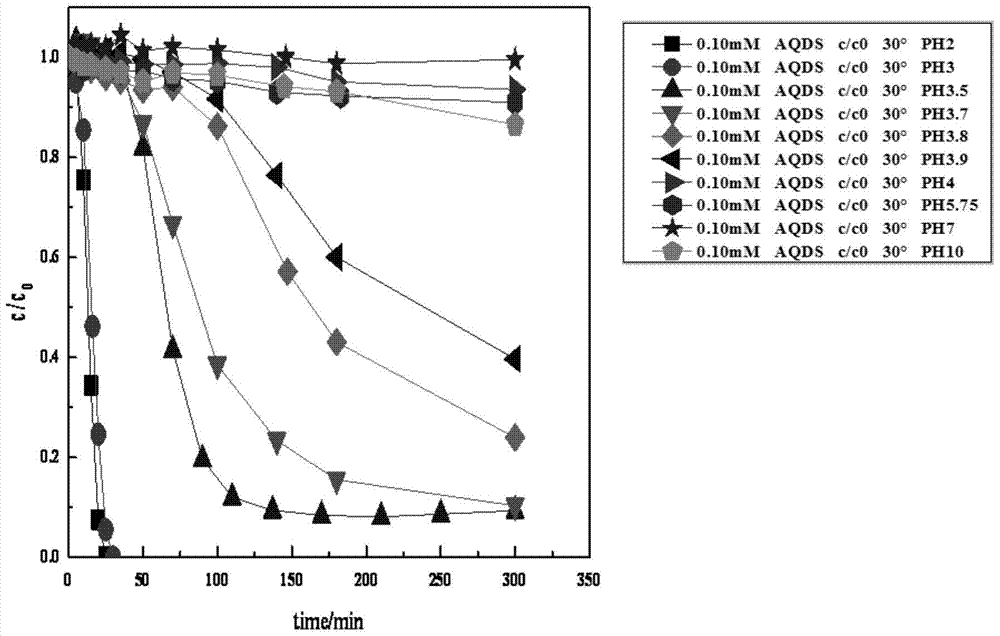

[0037] Step 1, in the rhodamine B waste water of 0.02mmol / L, add 2-sodium anthraquinone sulfonate (AQS), the concentration of 2-sodium anthraquinone sulfonate (AQS) in waste water is 0.10mmol / L, then use dilute H 2 SO 4 and NaOH to adjust the pH of each system to be 2, 3, 3.5, 3.7, 3.8, 3.9, 4, 5.75 (no pH adjustment), 7 and 10;

[0038] Step 2: Stir with a mechanical electronic stirrer, keep the rotation speed constant, the temperature is 30° C., and the reaction time is 300 min.

[0039] detected figure 2 The data, figure 2 is the degradation characteristics of Rhodamine B by AQS under different pH conditions, from figure 2 It can be known in the figure that when the concentration of AQS is a fixed value of 0.10mmol / L, and the pH is respectively 2, 3, 3.5, 3.7, 3.8, 3.9, 4, 5.75 (do not adjust the pH), 7 and 10, t...

Embodiment 3

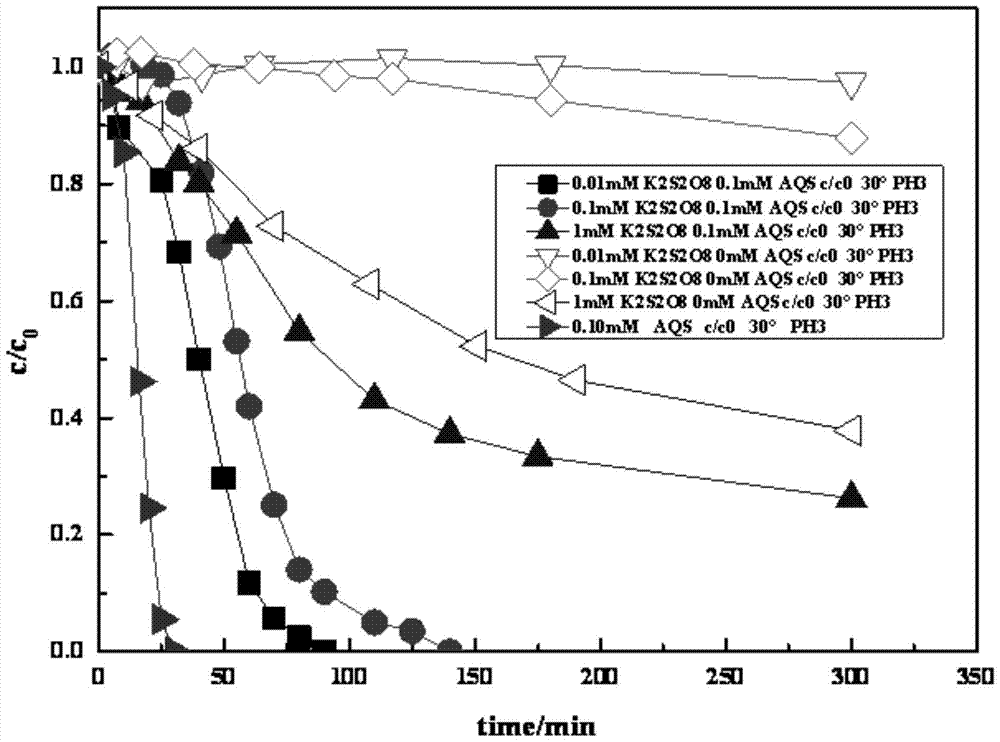

[0053] This embodiment provides a method for degrading printing and dyeing wastewater by anthraquinones, which specifically includes the following steps:

[0054] Step 1, in the rhodamine B waste water of 0.02mmol / L, add 2,6-sodium anthraquinone disulfonate (AQDS), the concentration of 2,6-sodium anthraquinone disulfonate (AQDS) in waste water is respectively 0mmol / L, 0.01mmol / L, 0.03mmol / L, 0.05mmol / L, 0.10mmol / L and 0.15mmol / L, and adjust the pH to 2 with dilute sulfuric acid;

[0055] Step 2: Stir with a mechanical electronic stirrer, keep the rotation speed constant, the temperature is 30° C., and the reaction time is 300 min.

[0056] detected Figure 4 The data, Figure 4 is the degradation characteristic of AQDS to rhodamine B under different concentration conditions, from Figure 4 It can be seen that when the concentration of AQS is 0mmol / L, 0.01mmol / L, 0.03mmol / L, 0.05mmol / L, 0.10mmol / L and 0.15mmol / L, the degradation rates of Rhodamine B are 0, 86 %, 96%, 97%, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com