Preparation method of blocky hybrid aerogel

A hybrid gas and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., to achieve the effects of low energy consumption, lower production costs, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of bulk hybrid airgel

[0034] (1) Measure 4.5mL tetraethyl orthosilicate, 2mL deionized water, 8mL acetonitrile in a beaker,

[0035] 0.4mL (0.008mol / L) oxalic acid, stir evenly and place in a water bath at 50°C for 10min. Take out the beaker and wait until it returns to room temperature, pipette 1mL of 3-aminopropyltriethoxysilane into the beaker, and add it dropwise while stirring. After a few minutes, it will gel, add 20mL of acetonitrile, and age for 2 hours.

[0036] (2) Soak the aged gel in 30 mL of acetonitrile solution with a mass fraction of 5% diisocyanate, and place it in a water bath at 40°C for 36 hours.

[0037] (3) Take out the cross-linked gel, add 20mL of acetonitrile, let it stand at room temperature for 24h, seal it with a plastic wrap with pinholes, and dry it in an oven at 60°C for 36h to obtain silica block airgel .

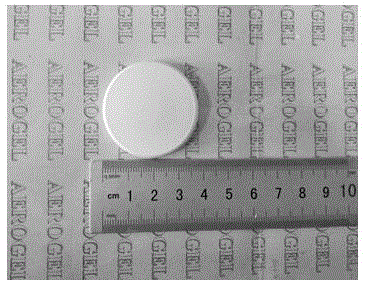

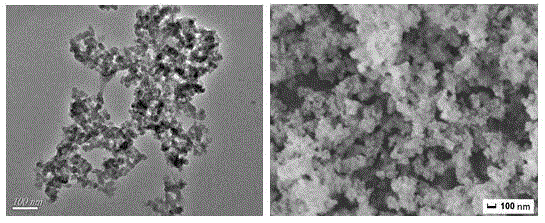

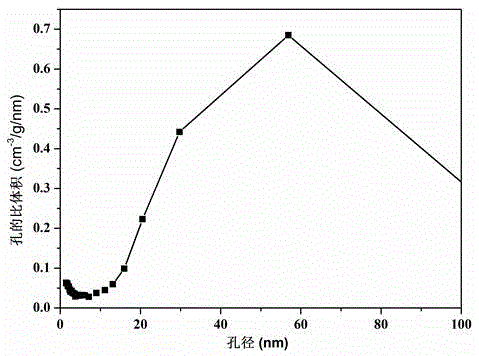

[0038] figure 1 It is a massive hybrid airgel prepared under normal pressure. As can be seen in the fig...

Embodiment 2

[0042] (1) Measure 4.5mL tetraethyl orthosilicate, 2mL deionized water, 8mL acetonitrile in a beaker,

[0043] 0.4mL (0.008mol / L) oxalic acid, stir evenly and place in a water bath at 30°C for 15min. Take out the beaker and wait for it to return to room temperature, pipette 0.8 mL of 3-aminopropyltriethoxysilane into the beaker with a pipette gun, and add it dropwise while stirring. After a few minutes, it will gel, add 30mL of acetonitrile, and age for 3 hours.

[0044] (2) Soak the aged gel in 20 mL of acetonitrile solution with a mass fraction of 5% diisocyanate, and place it in a water bath at 30°C for 28 hours.

[0045](3) Take out the cross-linked gel, add 30mL of acetonitrile, let it stand at room temperature for 18h, seal it with a plastic wrap with pinholes, and dry it in an oven at 50°C for 48h to obtain silica block airgel .

Embodiment 3

[0047] (1) Measure 4.5mL tetraethyl orthosilicate, 2mL deionized water, 8mL acetonitrile in a beaker,

[0048] 0.4mL (0.008mol / L) oxalic acid, stir evenly and place in a water bath at 60°C for 8 minutes. Take out the beaker and wait for it to return to room temperature, pipette 1.2mL of 3-aminopropyltriethoxysilane into the beaker with a pipette gun, and add it dropwise while stirring. After a few minutes, it will gel, add 40mL of acetonitrile, and age for 5 hours.

[0049] (2) Soak the aged gel in 40 mL of acetonitrile solution with a mass fraction of 5% diisocyanate, and place it in a water bath at 60°C for 24 hours.

[0050] (3) Take out the cross-linked gel, add 40mL of acetonitrile, let it stand at room temperature for 12h, seal it with a plastic wrap with pinholes, and dry it in an oven at 100°C for 30h to obtain silica block airgel .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com