Comprehensive rubbish sorting technology and comprehensive rubbish sorting machine

A comprehensive separation and garbage technology, which is applied in the direction of solid separation, separation of solids from solids by air flow, and sieving, etc., can solve the problems of insufficient recycling of garbage, inability to sort out, and incomplete sorting. To achieve the effect of convenient recycling and utilization, compact structure, material sorting and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

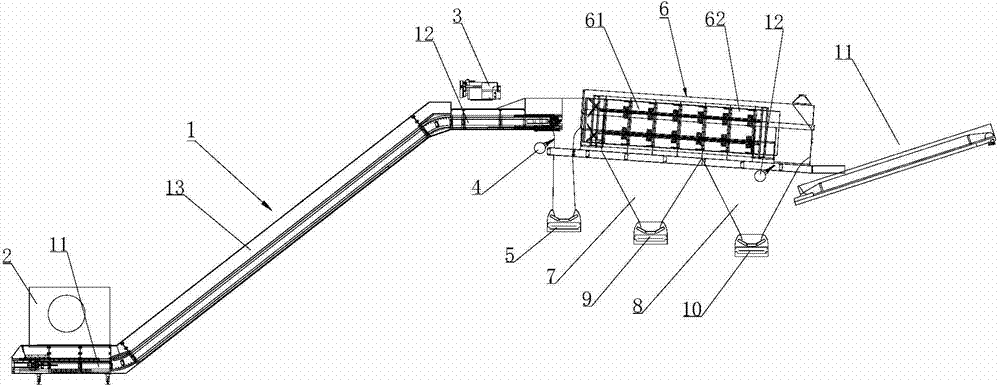

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] A garbage comprehensive sorting process is composed of the following procedures:

[0019] 1) Breaking bags with even materials: realize bagged garbage bag breaking and primary crushing of large disturbing objects;

[0020] 2) Magnetic separation: pass the garbage processed in the first step through a magnetic separator to separate the magnetic metals in the garbage;

[0021] 3) The first wind selection: the waste after the second step of magnetic separation is carried out by air separation, and the construction waste with a relatively large proportion in the waste is separated from other wastes. The common construction waste waste consists of bricks, stones, etc.

[0022] 4) Put the construction waste removed in the third step into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com