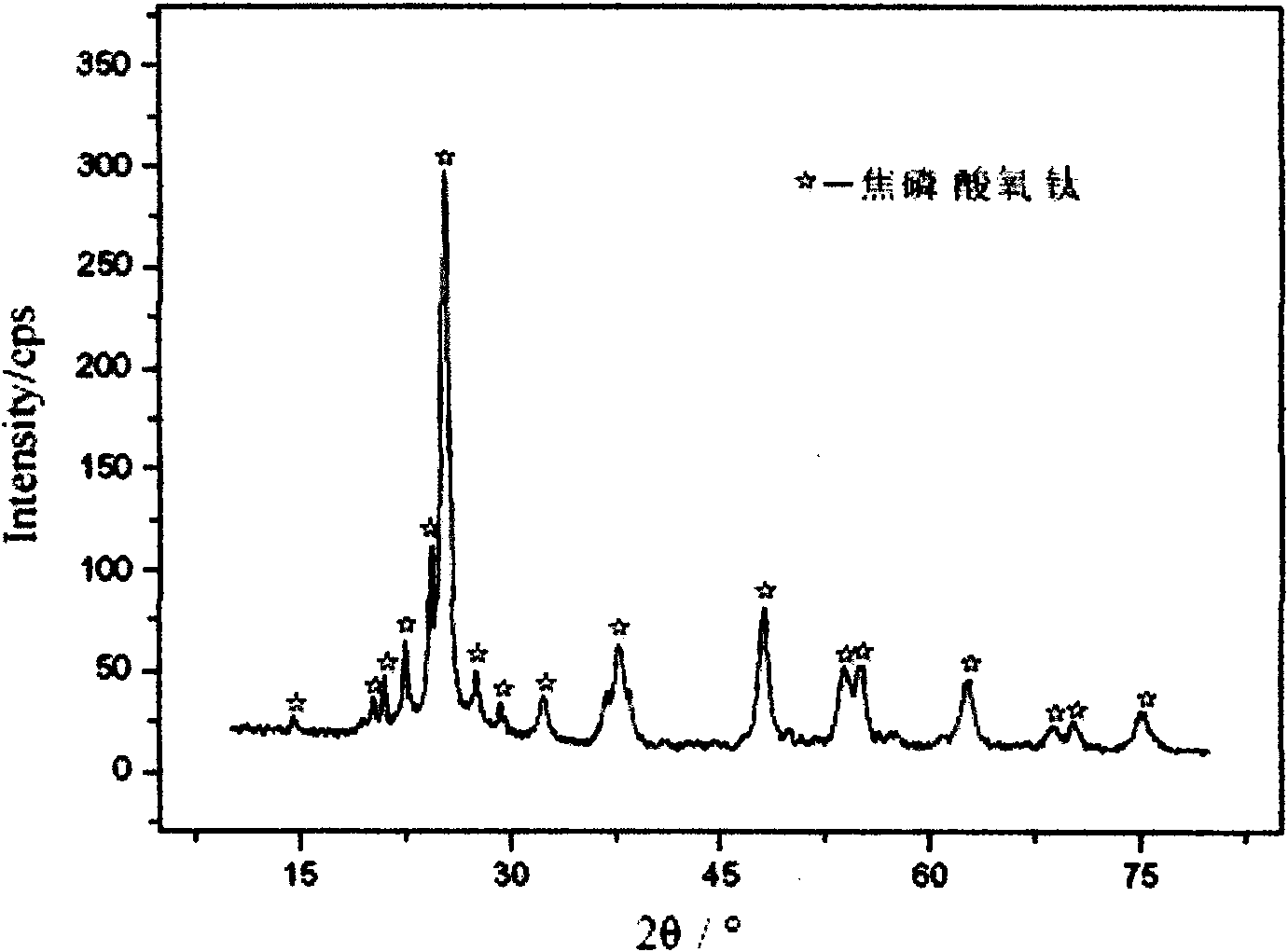

Nano titanyl pyrophosphate photocatalyst and preparation method thereof

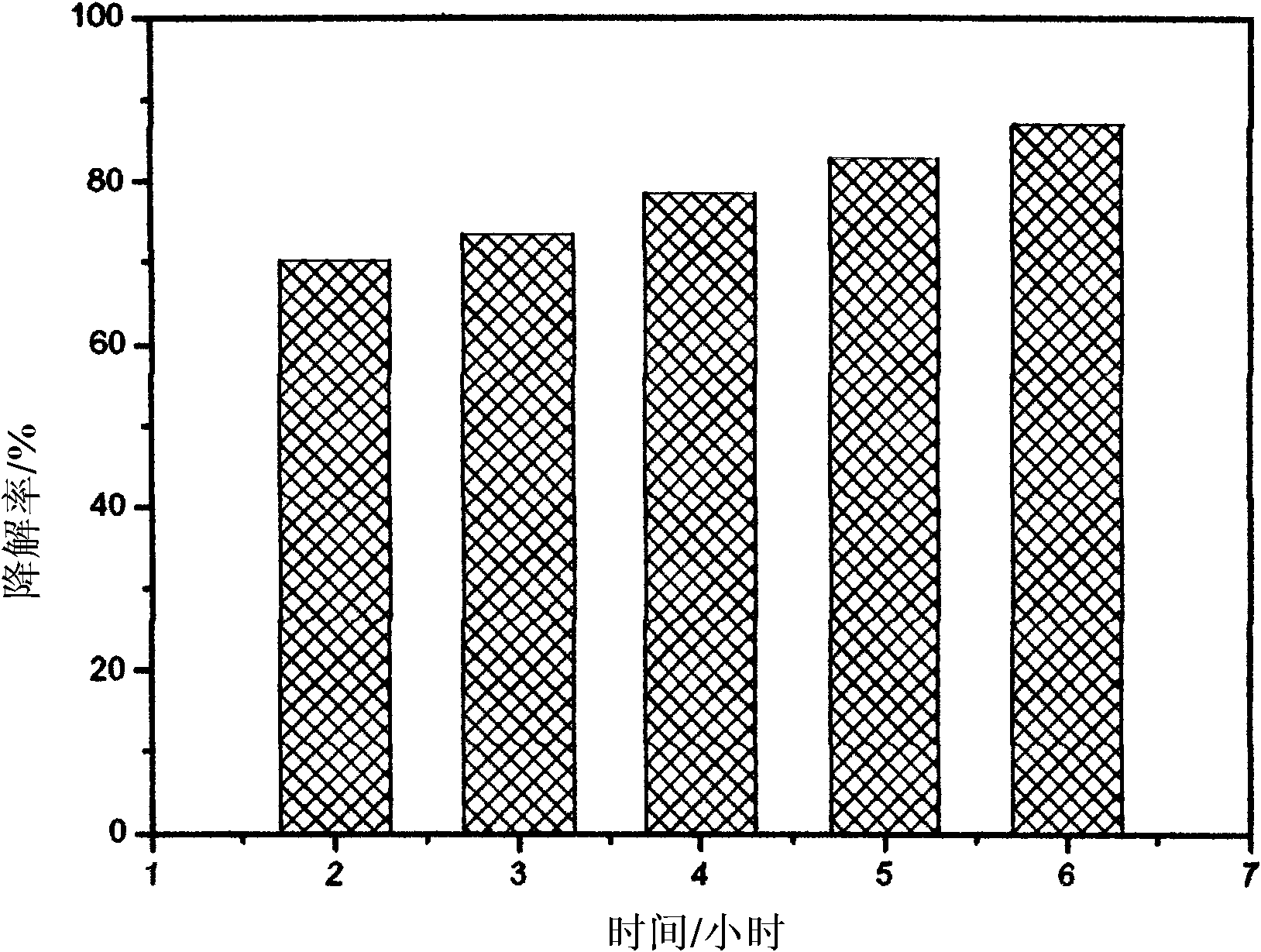

A technology of titanyl pyrophosphate and titanyl phosphate, applied in the field of photocatalyst, can solve the problems of photocatalytic performance and application that have not been reported, and achieve the effects of excellent photocatalytic degradation performance, stable physical and chemical properties, and significant application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 2.0 grams of PVP into deionized water, stir until completely dissolved at room temperature, then dissolve 77.25 grams of 20% titanium trichloride in deionized water containing PVP, add deionized water to make the solution volume reach 1 liter and obtain a titanium concentration of 0.1 mol / liter solution A, then add 800 milliliters of sodium hydroxide aqueous solution with a concentration of 0.5 mol / liter to the prepared solution A under stirring, and continue stirring for 5 minutes after adding all the sodium hydroxide solution to obtain a yellow oily suspension Liquid B; then add 100 milliliters of aqueous hydrogen peroxide solution with a concentration of 1 mol / liter to the suspension B under stirring, and continue stirring for 10 minutes after all the hydrogen peroxide is added to obtain a light yellow oily suspension C; Add 1000.0 ml of phosphoric acid with a concentration of 0.1 mol / L to the suspension C under stirring, continue to stir for 10 minutes after all ...

Embodiment 2

[0035] Add 4.6 grams of sodium polyacrylate into deionized water, stir at room temperature until completely dissolved, then dissolve 475 grams of 20% titanium tetrachloride in deionized water containing sodium polyacrylate, add deionized water to make the solution volume reach 1 liter Promptly obtain a solution A with a titanium concentration of 0.5 mol / liter, then add 2000 milliliters of aqueous ammonia with a concentration of 1.0 mol / liter to the prepared solution A under stirring, and continue stirring for 10 minutes after all the ammonia is added to obtain a white oily suspension B; then add 250 milliliters of aqueous hydrogen peroxide solution with a concentration of 2 mol / liter to the suspension B under stirring, and continue to stir for 15 minutes after all the hydrogen peroxide is added to obtain a white oily suspension C; then add 500.0 milliliters Add sodium hydrogen pyrophosphate with a concentration of 0.5 mol / liter into the suspension C under stirring, continue sti...

Embodiment 3

[0038] Add 1.0 g of P123 into deionized water, stir at room temperature until completely dissolved, then dissolve 950 g of 20% titanium tetrachloride in deionized water containing P123, add deionized water to make the solution volume reach 1 liter to obtain the titanium concentration 1.0 mol / liter solution A, then add 1000 milliliters of potassium hydroxide aqueous solution with a concentration of 4.0 mol / liter to the prepared solution A under stirring, and continue stirring for 15 minutes after adding all the potassium hydroxide solution to obtain a white oil Suspension B; then add 250 milliliters of aqueous hydrogen peroxide solutions with a concentration of 4 mol / liter to the suspension B under stirring, and continue stirring for 15 minutes after hydrogen peroxide has been added to obtain a white oily suspension C; then Add 1250.0 ml of ammonium phosphate with a concentration of 0.8 mol / L to the suspension C under stirring, continue to stir for 20 minutes after all the ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com