Automatic loading device

An automatic, vertical technology used in conveyor controls, loading/unloading, transportation and packaging to reduce space requirements, improve loading and stacking efficiency, and reduce stacking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

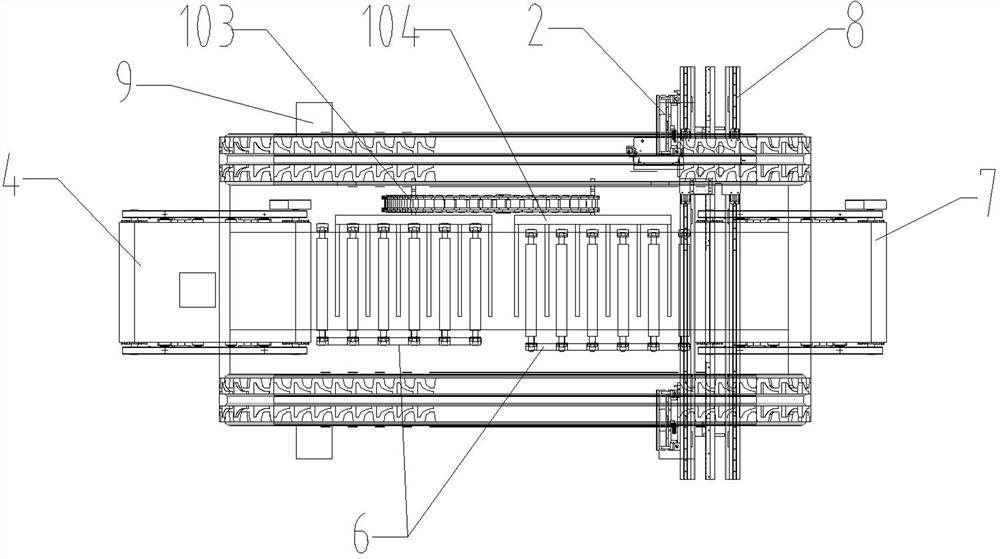

[0050] In embodiment 1 such as figure 2 As shown in , the front, rear, left, and right sides of the self-moving car 4 are provided with a laser range finder 9, and the laser range finder 9 measures the distance between the self-moving car 4 and the surrounding compartments.

Embodiment 2

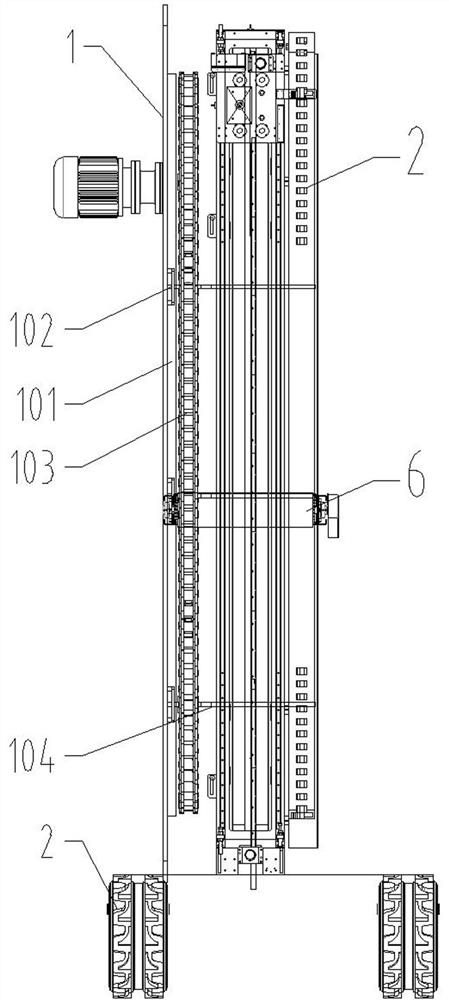

[0051] Embodiment 2, another kind of forward moving frame, mechanism is the suspension truss 5 that stretches forward, as Figure 10 and Figure 11 shown in . The circulation lifting conveyor 1 and the material pick-and-place elevator 2 are suspended on the front deep suspension truss 5 with suspended travel.

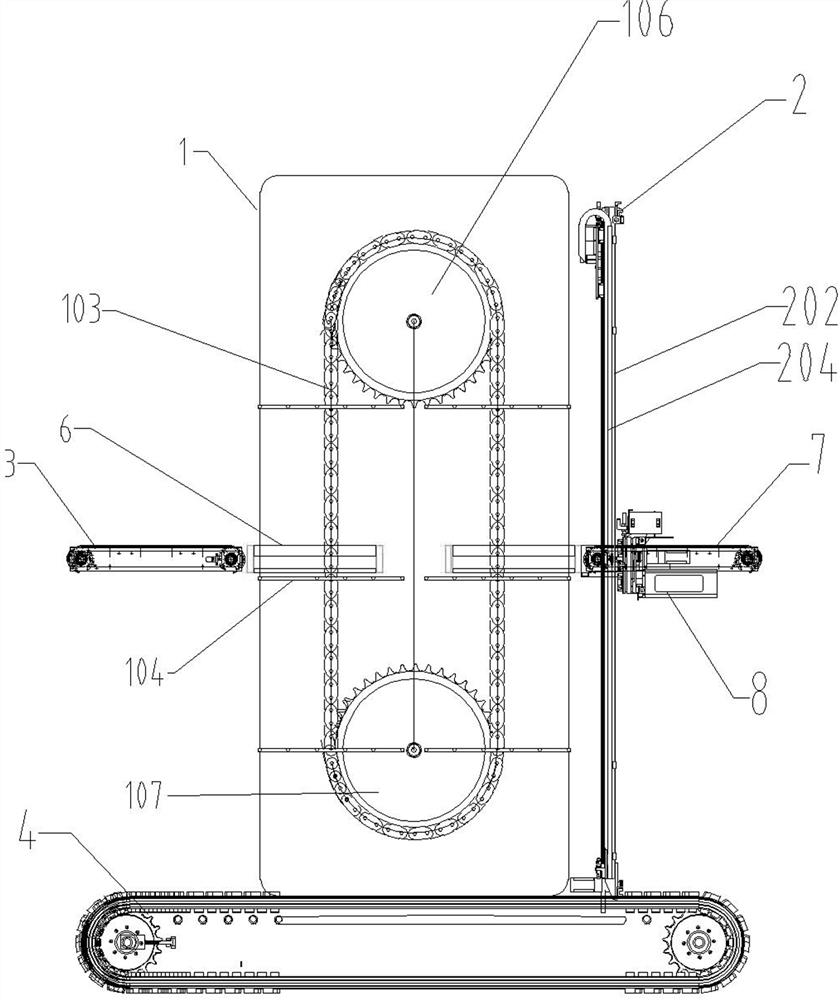

[0052] After the material enters the main conveyor, it enters the pick-and-feed idler 6, and the circulation platform 104, which is always in a horizontal state on the material pick-and-place elevator 2, goes down from the right side along the track, then enters the left track through the lower semicircular track, and then Upwards, the circulation platform 104 meets the pick-up and delivery roller 6, lifts the material on the pick-up and delivery roller 6, and moves to the right side of the track with the chain, and the circulation platform 104 goes down to meet the pick-up and placement elevator 2 on the material. The feeding rollers 6 converge, and the materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com