Grooving-machine flip discharge device for laminate flooring

A technology of unloading device and reinforced floor, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of insufficient heat dissipation of plates, and achieve the effect of neat arrangement, compact and reasonable structure, and accurate automatic stacking position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

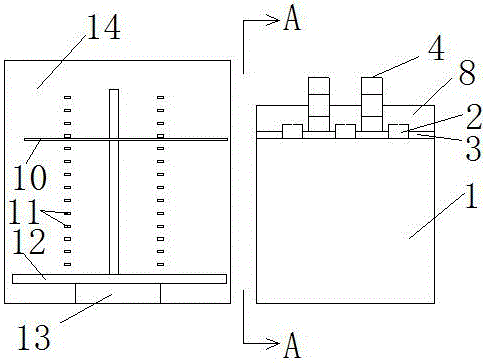

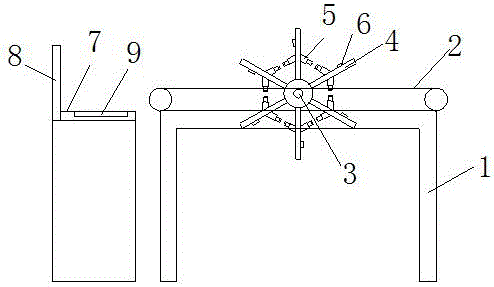

[0014] As shown in the figure, the turning plate unloading device of the slotting machine used for laminate flooring according to the present invention includes a bracket 1, and a conveyor belt 2 is arranged above the bracket 1, and the conveyor belt 2 is arranged as a plurality of conveyor belts 2 arranged in parallel at intervals , a rotating shaft 3 is arranged below the middle of a plurality of conveyor belts 2, a support rod 4 surrounding the rotating shaft 3 is evenly arranged on the circumference of the rotating shaft 3 between two adjacent conveyor belts 2, and the upper end of the supporting rod 4 protrudes from the The conveyor belt 2 is symmetrically provided with fixed push rods 5 on both sides of each support rod 4 , and an induction device 6 is provided outside one of the fixed push rods 5 .

[0015] Preferably, at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com