Method for producing electrolytic manganese metal by comprehensively utilizing electrolytic manganese residues

A technology of electrolytic manganese metal and electrolytic manganese slag, which is applied in the direction of cement production, manganese sulfate, process efficiency improvement, etc., can solve the problems of small manganese slag utilization and immature technology, reduce stockpiling, improve economic and social Benefits, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

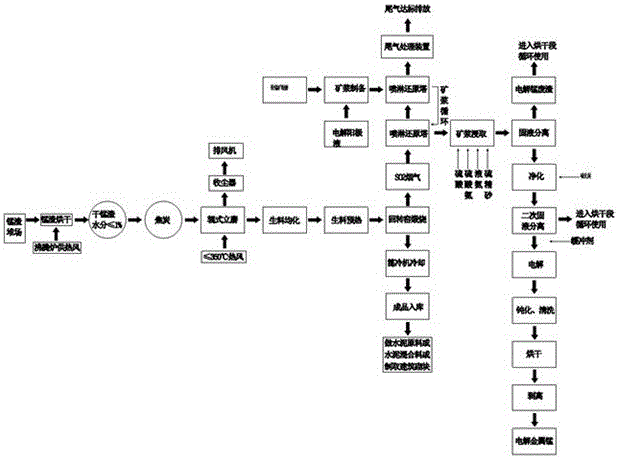

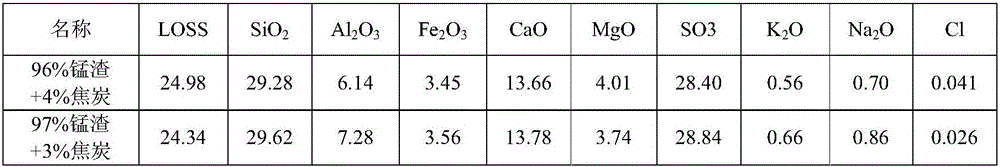

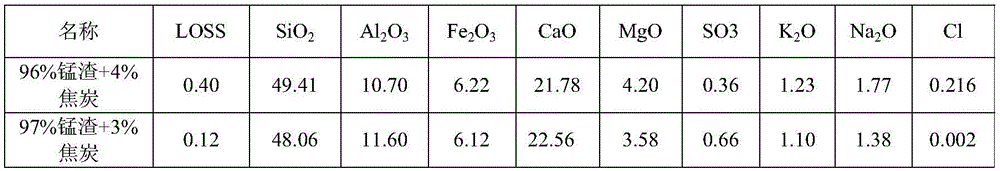

[0018] A method for comprehensively utilizing electrolytic manganese slag to produce electrolytic metal manganese comprises drying the electrolytic manganese metal slag and grinding coke at a ratio of 96% manganese slag+4% coke until the sieve residue on an 80 μm square hole sieve is ≤10%. Grind pyrolusite MnO2 to a fineness of 200 meshes, and make slurry with electrolytic anolyte. After the raw material after grinding is homogenized and qualified, it is sent to the preheater for waste heat to 600°C-700°C and then enters the rotary kiln for calcination. SO produced after calcination 2 After the reduction tower reacts with the pyrolusite pulp, the MnO in the pyrolusite pulp 2 and SO in calcination flue gas 2 Oxidation-reduction reactions occur to generate MnSO4 slurry. In the prepared MnSO 4 Add manganese in depth such as sulfur concentrate sand to the slurry. The slurry after deep manganese immersion is separated into solid and liquid by a plate filter press, and the sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com