Method utilizing waste gypsum slag to manufacture green microcrystalline glass plate material

A technology of glass-ceramic and waste gypsum, which is applied in the direction of solid waste removal, etc., can solve the problems of aggravating the erosion of molten glass on refractory materials of furnaces, aggravating the erosion of molten glass on refractory materials of furnaces, and high melting temperature of glass, so as to improve the melting temperature. kiln efficiency, reduced energy consumption and increased melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

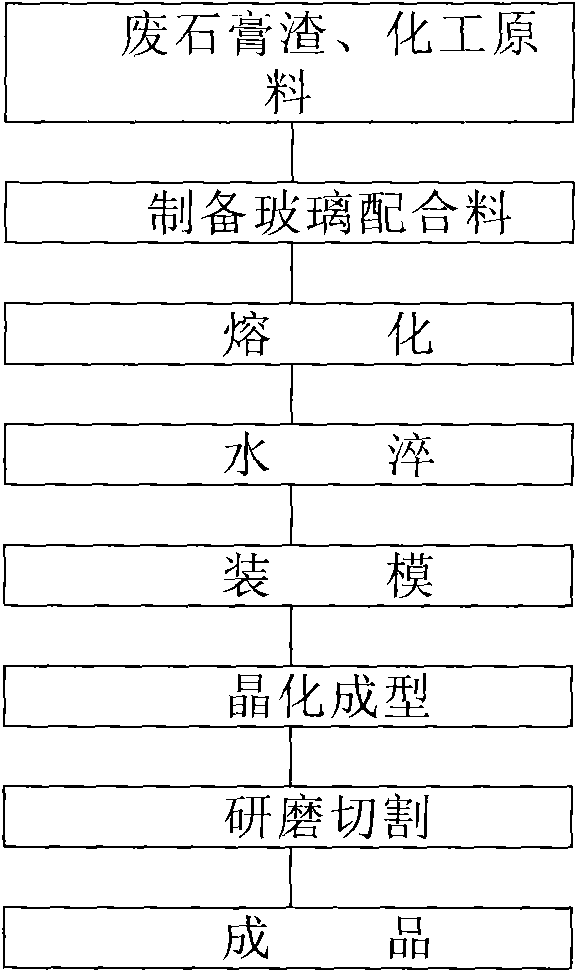

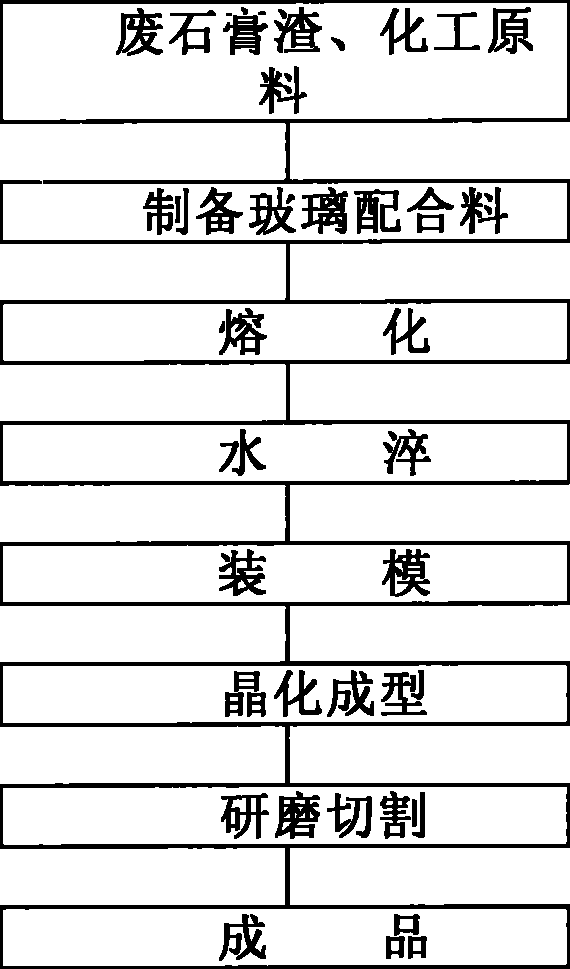

Method used

Image

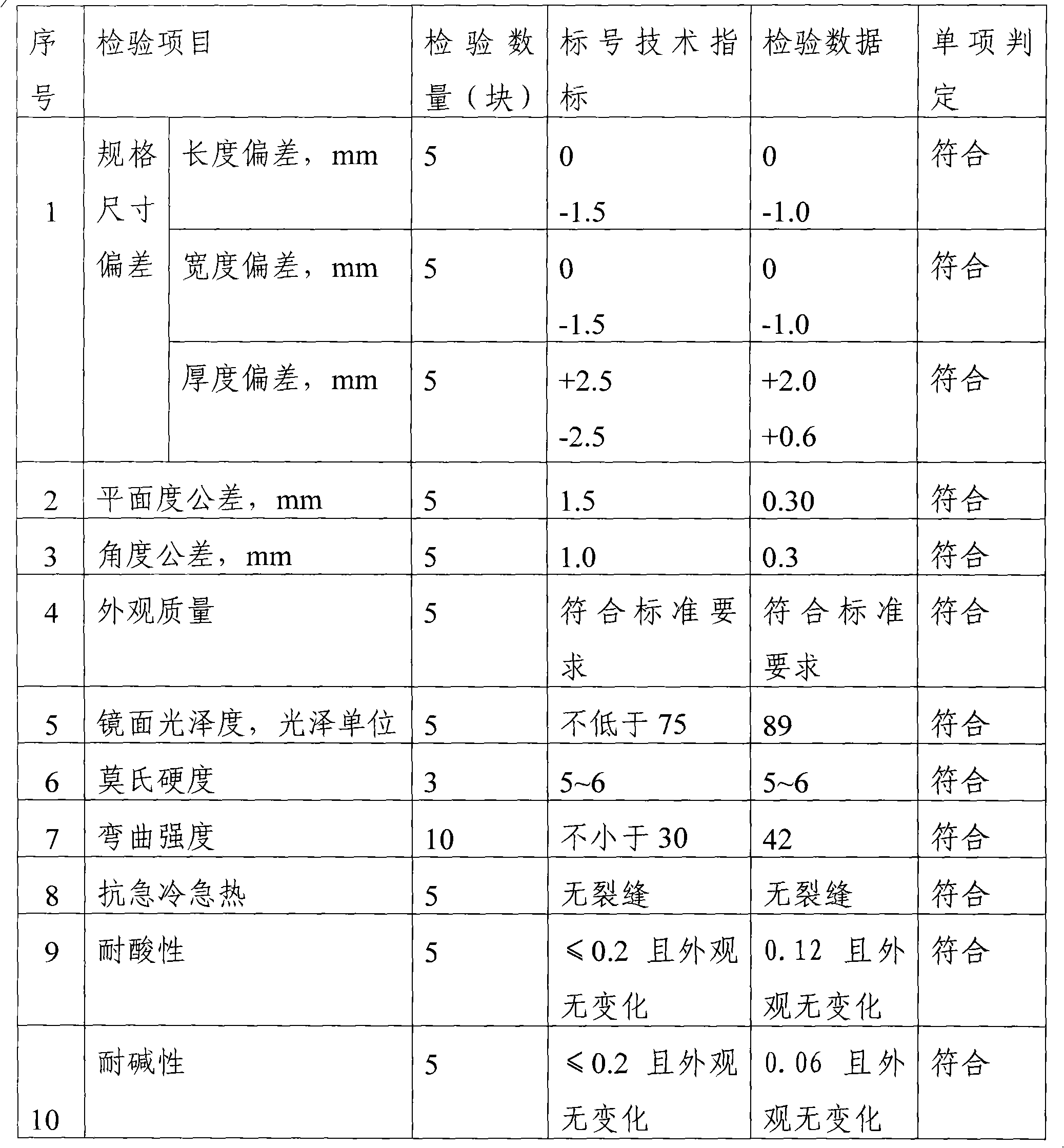

Examples

Embodiment 1

[0019] The glass batch is made by weighing and mixing. The composition of the glass batch is calculated by weight: 60 parts of waste gypsum slag, 26 parts of quartz sand, 15 parts of lithium feldspar, 4 parts of soda ash, 2 parts of zinc oxide, barium carbonate 4 parts, 2 parts of chromium oxide, 0.2 parts of copper oxide, 0.04 parts of carbon powder.

[0020] Put the above-mentioned glass batch material in a mullite crucible and melt it in a box-type electric furnace at a temperature of 1480°C for 3 hours. After the melting is completed, pour the glass liquid into water to become glass pellets. 700 grams of glass granules were spread flat in a refractory mold with a size of 120×120 mm, and crystallized in a box-type electric furnace at a crystallization temperature of 1020° C. Green glass-ceramic plates with a size of 120×120×18 mm can be obtained after grinding and cutting the crude green glass-ceramics.

Embodiment 2

[0022] The glass batch is made by weighing and mixing. The composition of the glass batch is calculated by weight: 50 parts of waste gypsum slag, 33 parts of quartz sand, 15 parts of lithium feldspar, 3 parts of soda ash, 3 parts of zinc oxide, barium carbonate 4 parts, chromium oxide 2.2 parts, copper oxide 0.06 parts, carbon powder 0.1 parts.

[0023] The above-mentioned glass batch materials were melted in a glass tank furnace with a temperature of 1480° C. for 3 hours, and after the melting was completed, the molten glass was directly poured into water to become glass pellets. 26 kg of glass granules were spread flat in a refractory mold with a size of 6000×9000 mm and crystallized in a shuttle kiln fueled by liquefied petroleum gas, with a crystallization temperature of 1060°C. Green glass-ceramic plates of 600×900×18 mm can be obtained after grinding and cutting the crude green glass-ceramics.

Embodiment 3

[0025] The glass batch is made by weighing and mixing. The composition of the glass batch is calculated in parts by weight: 40 parts of waste gypsum slag, 38 parts of quartz sand, 24 parts of lithium feldspar, 7 parts of limestone, 2 parts of soda ash, 2 parts of zinc oxide parts, 4 parts of barium carbonate, 2.5 parts of chromium oxide, and 0.2 parts of carbon powder.

[0026] The above-mentioned glass batch materials were melted in a glass tank kiln at a temperature of 1480° C. for 3 hours, and after the melting was completed, the molten glass was directly flowed into water to become glass pellets. Spread 26 kg of glass pellets in a refractory mold with a size of 6000×9000 mm and crystallize in a shuttle kiln fueled by liquefied petroleum gas at a crystallization temperature of 1050°C. Green glass-ceramic plates of 600×900×18 mm can be obtained after grinding and cutting the crude green glass-ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com