Method for recovering germanium from germanium extraction residues

A residue and filter residue technology, applied in the field of secondary extraction of germanium, can solve the problem of less than 70% recovery rate, and achieve the effects of reducing stockpiling, making full use of it and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

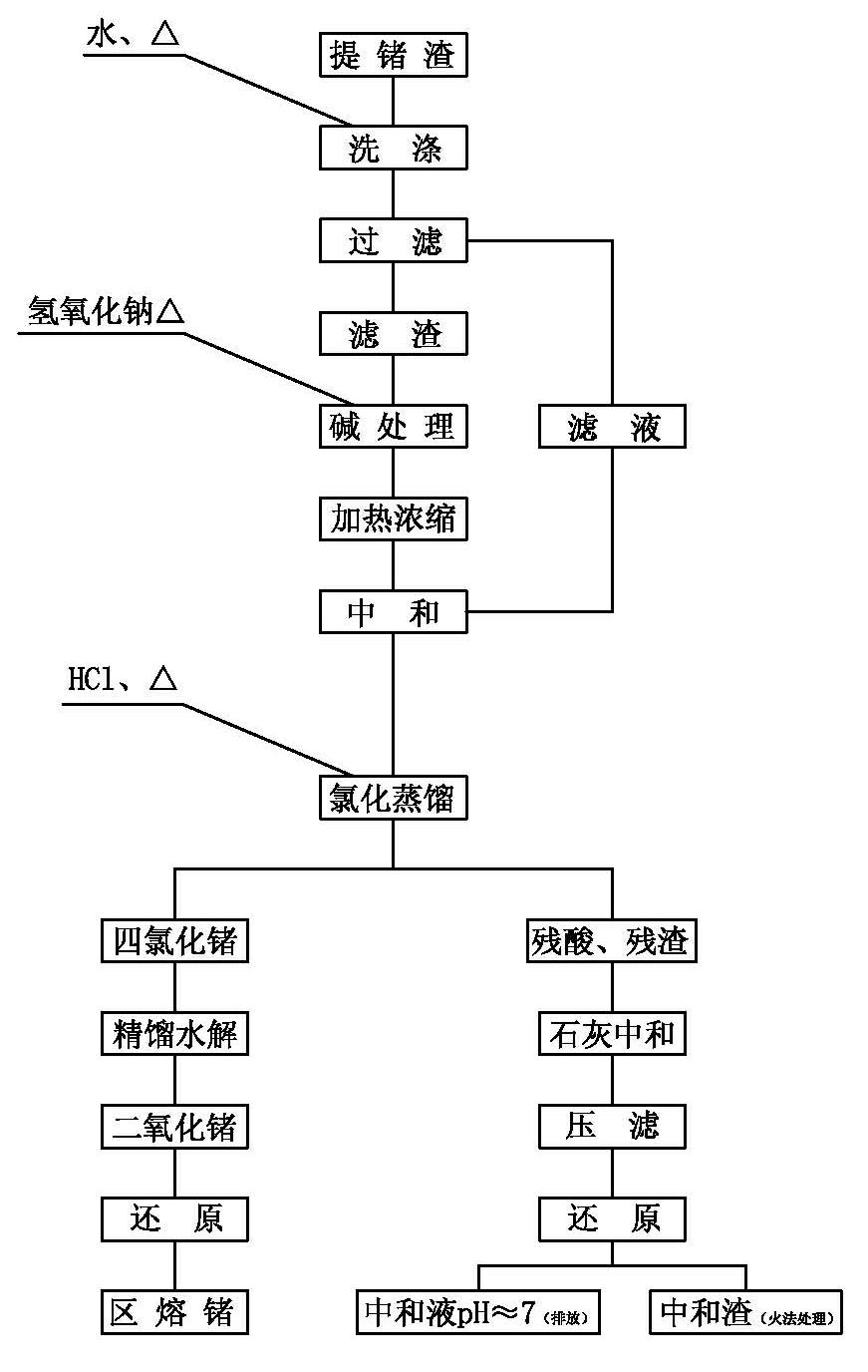

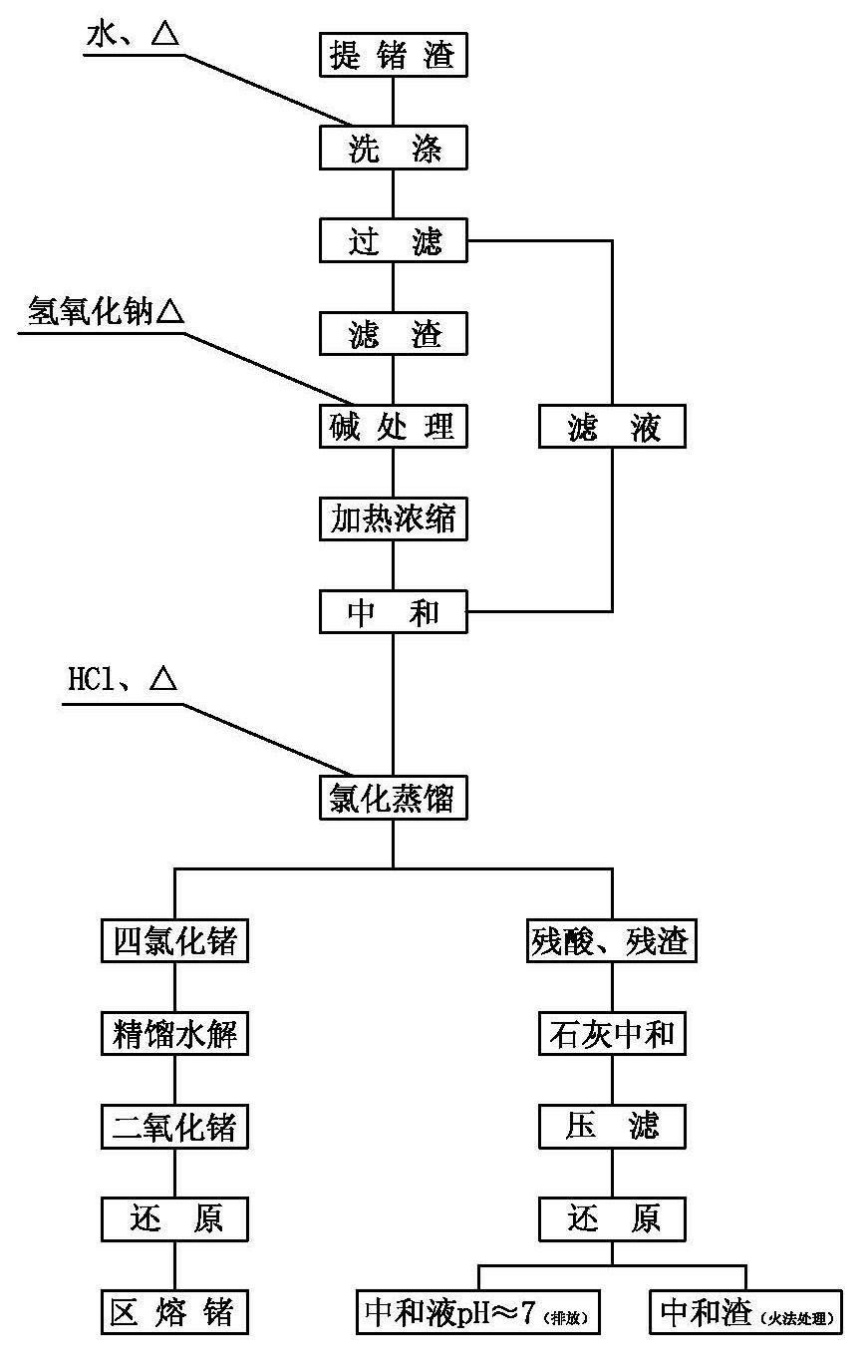

Method used

Image

Examples

Embodiment 1

[0034]Step 1: Put 500g of germanium extraction residue, with a moisture mass fraction of 52.40%, a residual wet germanium mass fraction of 0.26%, and a metal content of 1.30g, into a 5000mL Erlenmeyer flask, add 1000mL of tap water, and start the stirrer to stir evenly , placed on an electric furnace, heated to 80-85°C, stirred at 115 rpm, stirred and washed for 30 minutes, vacuum filtered, and 950 mL of filtrate was obtained. Because the filtrate contains a large amount of hydrochloric acid and germanium, it can be used as an alkali treatment, concentrated and neutralized for later use. Wash the filtered filter residue three times with 50 mL of boiling water, wash and filter to dry the water, and then transfer the washed filter residue to the original Erlenmeyer flask.

[0035] Step 2: Put the triangular flask on the temperature-controlled electric furnace, add 75g of sodium hydroxide and 1000mL of tap water, start the mechanical stirrer, the stirring speed is 115 rpm, after s...

Embodiment 2

[0040] Step 1: Put 500g of germanium extraction residue, with a moisture mass fraction of 56.12%, a residual wet germanium mass fraction of 0.68%, and a metal content of 3.4g, in a 5000mL Erlenmeyer flask, add 1250mL of tap water with a residue weight of 1250mL, and start the stirrer to stir After uniformity, place on an electric furnace and heat to 80-85°C, stir at 115 rpm, stir and wash for 40 minutes, and vacuum filter to obtain 980 mL of washing filtrate. Because the washing filtrate contains a large amount of hydrochloric acid and germanium, it is treated as an alkali and then concentrated and neutralized. Standby, wash the filtered filter residue three times with 60mL boiling water, wash and filter the water, and then transfer the washed filter residue to the original Erlenmeyer flask.

[0041] Step 2: Put the triangular flask on the temperature-controlled electric furnace, add 87.5g of sodium hydroxide and 1100mL of tap water, start the mechanical stirrer, the stirring s...

Embodiment 3

[0046] Step 1: Put 500g of germanium extraction residue, with a moisture mass fraction of 54.10%, a residual wet germanium mass fraction of 1.21%, and a metal content of 6.050g, into a 5000mL Erlenmeyer flask, add 1500mL of tap water with the weight of the residue, and start the stirrer to stir After uniformity, place on an electric furnace and heat to 85-90°C, stir at 120 rpm, stir and wash for 45 minutes, and vacuum filter to obtain 990 mL of washing filtrate. Because the washing filtrate contains a large amount of hydrochloric acid and germanium, it is treated as an alkali and then concentrated and neutralized. Standby, wash the filter residue three times with 75mL boiling water, filter the water after washing, and then transfer the washed filter residue to the original Erlenmeyer flask.

[0047] Step 2: Put the triangular flask on the temperature-controlled electric furnace, add 100g of sodium hydroxide and 1250mL of tap water, start the mechanical stirrer, the stirring spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com