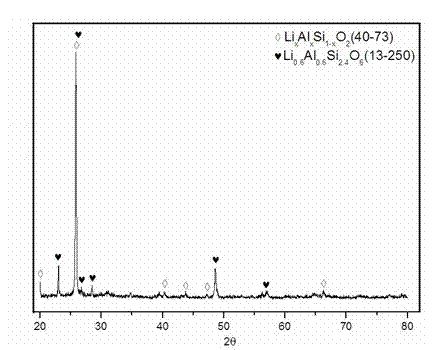

Method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings

A technology of microwave heat treatment and glass-ceramics, which is applied in the field of producing low-expansion glass-ceramics by using microwave heat-treatment of gold tailings, can solve the problems of high cost of glass-ceramics, high glass melting temperature, and long crystallization time, etc. The effect of product quality control, energy saving, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

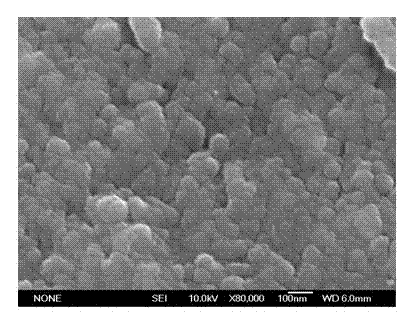

[0023] Embodiment 1: The method for producing low-expansion glass-ceramic by microwave heat treatment of gold tailings comprises the following steps:

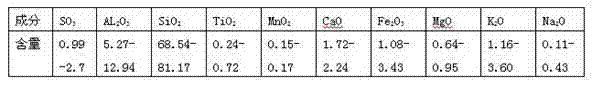

[0024] 1) Accurately weigh 44kg of gold tailings, 23kg of quartz, 15kg of alumina, 9kg of lithium carbonate, 2.5kg of magnesium oxide, 3kg of titanium oxide, 0.5kg of zirconia, and 3kg of borax, and add the above raw materials into the mixer and mix evenly. Obtain batch material; The particle diameter of above-mentioned raw material is all less than 0.088mm;

[0025] 2) Put the batch material in an alumina crucible, and then put the crucible into an industrial microwave oven. The batch material is heated and melted by microwave to obtain molten glass. When melting, the temperature is raised to 1350 °C at a heating rate of 10 °C per minute, and at this temperature Keep warm for 25 minutes;

[0026] 3) The molten glass is molded by casting, and then placed in an industrial microwave oven with a power of 60KW for annealing treatm...

Embodiment 2

[0029] Embodiment 2: The method for producing low-expansion glass-ceramics by microwave heat treatment of gold tailings comprises the following steps:

[0030] 1) Accurately weigh 46kg of gold tailings, 23kg of quartz, 14kg of alumina, 10kg of lithium carbonate, 2kg of magnesium oxide, 3kg of titanium oxide, 1kg of zirconia, and 1kg of borax. Material; The particle diameter of above-mentioned raw material is all less than 0.088mm;

[0031] 2) Put the batch material in an alumina crucible, then put the crucible into a microwave oven, and melt the batch material through microwave heat treatment to obtain molten glass; when melting, the temperature is raised to 1450 °C at a rate of 10 °C per minute, and kept for 20 minutes;

[0032] 3) Cast the molten glass into shape, then place it in a 40KW industrial microwave oven, and undergo microwave annealing treatment at a temperature of 620°C and a holding time of 35 minutes;

[0033] 4) Continue microwave heating to raise the temperat...

Embodiment 3

[0035] Embodiment 3: The method for producing low-expansion glass-ceramic by microwave heat treatment of gold tailings comprises the following steps:

[0036] 1) Accurately weigh 40kg of gold tailings, 25kg of quartz, 16kg of alumina, 11kg of lithium carbonate, 2kg of magnesium oxide, 3kg of titanium oxide, 0.5kg of zirconia, and 2.5kg of borax, and add the above raw materials into the mixer and mix evenly. Obtain batch material; Above-mentioned raw material particle size is all less than 0.088m;

[0037] 2) Put the batch material in an alumina crucible and put the crucible into a microwave oven, and melt it through microwave heat treatment to obtain molten glass; when melting, the temperature is raised to 1400°C at a rate of 10°C per minute, and kept at this temperature for 30 minutes;

[0038] 3) Cast the molten glass into shape, then place it in a 30KW industrial microwave oven, and undergo microwave annealing treatment at a temperature of 600°C and a holding time of 25 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com