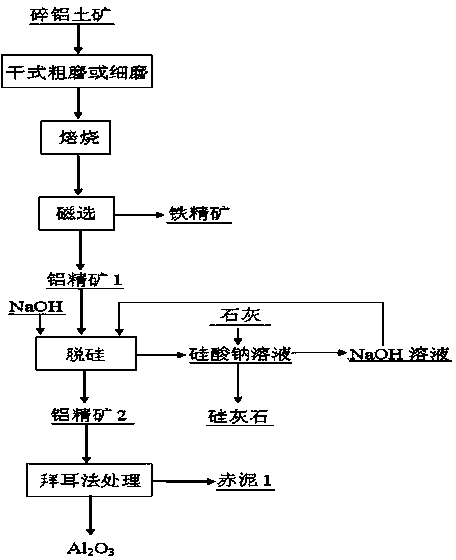

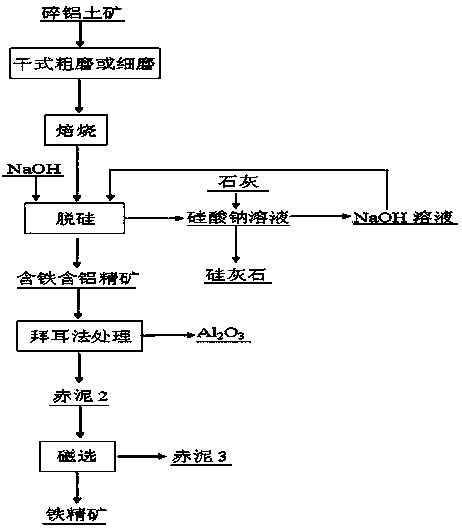

Bauxite comprehensive utilization method

A technology of bauxite and aluminum concentrate, applied in the direction of alkaline earth metal silicate, improvement of process efficiency, alumina/aluminum hydroxide, etc., can solve problems such as complex process flow, achieve high economic and environmental benefits, reduce Effect of alkali consumption and reduction of stockpiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Al in bauxite 1 2 o 3 Content is 41.20%, SiO 2 The iron oxide content is 9.18%, and the iron oxide content is 30%. The bauxite 1 is crushed and coarsely ground to obtain a coarse ore powder with a thickness of less than 2.5 mm. The coarse ore powder was roasted in a fluidized roaster for 65 minutes in a reducing atmosphere to obtain roasted coarse ore powder. The roasting temperature was 800°C, and the CO content in the roaster was controlled to be 2.5%. The roasted coarse ore powder is finely ground with a ball mill until the content of the -75 μm particle size is 75%, and then subjected to magnetic separation treatment to obtain an iron concentrate with an iron content of 62%. The aluminum concentrate obtained by magnetic separation and iron removal is desiliconized with high-fraction lye to obtain desiliconized aluminum concentrate and sodium silicate lye. L, the molecular ratio is 40, the liquid-solid ratio is 3.0, and the reaction time is 180 minutes. The alumin...

Embodiment 2

[0055] Al in bauxite 1 2 o 3 Content is 41.20%, SiO 2 The iron oxide content is 9.18%, and the iron oxide content is 30%. The bauxite 1 is crushed and finely ground to obtain a fine ore powder with a particle size content of -0.3mm of 100% and a particle size content of -75μm of 65%. The fine ore powder was roasted in a fluidized roaster for 5s under a reducing atmosphere at a temperature of 1100°C, and the CO content in the roaster was controlled to be 1.5%. The roasted fine ore powder is processed by magnetic separation to obtain iron concentrate and aluminum concentrate with an iron content of 52%; Sodium acid lye, the temperature of desiliconization treatment is 105°C, the caustic concentration Nk is 150g / L, the molecular ratio is 50, the liquid-solid ratio is 5.0, and the reaction time is 10min. The aluminum recovery rate is 82%. The temperature of the sodium silicate-containing lye is 105°C, the amount of lime added is 1.4 times the theoretical amount, the reaction t...

Embodiment 3

[0057] Al in bauxite 1 2 o 3 Content is 41.20%, SiO 2 The iron oxide content is 9.18%, and the iron oxide content is 30%. The bauxite 1 is crushed and coarsely ground to obtain a coarse ore powder with a thickness of less than 1.5 mm. The coarse ore powder was roasted in a fluidized roaster for 30 minutes in a reducing atmosphere to obtain roasted coarse ore powder. The roasting temperature was 950°C, and the CO content in the roaster was controlled at 2.8%. The roasted coarse ore powder is finely ground with a ball mill until the content of -75 μm particle size is 85%, and the iron concentrate and aluminum concentrate with an iron content of 56% are obtained by magnetic separation. The aluminum concentrate is desiliconized with a high-fraction lye to obtain a desiliconized aluminum concentrate and a lye containing sodium silicate. The temperature of the desiliconization treatment is 105°C, the caustic concentration Nk is 150g / L, and the molecular ratio is 40. The liquid-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com