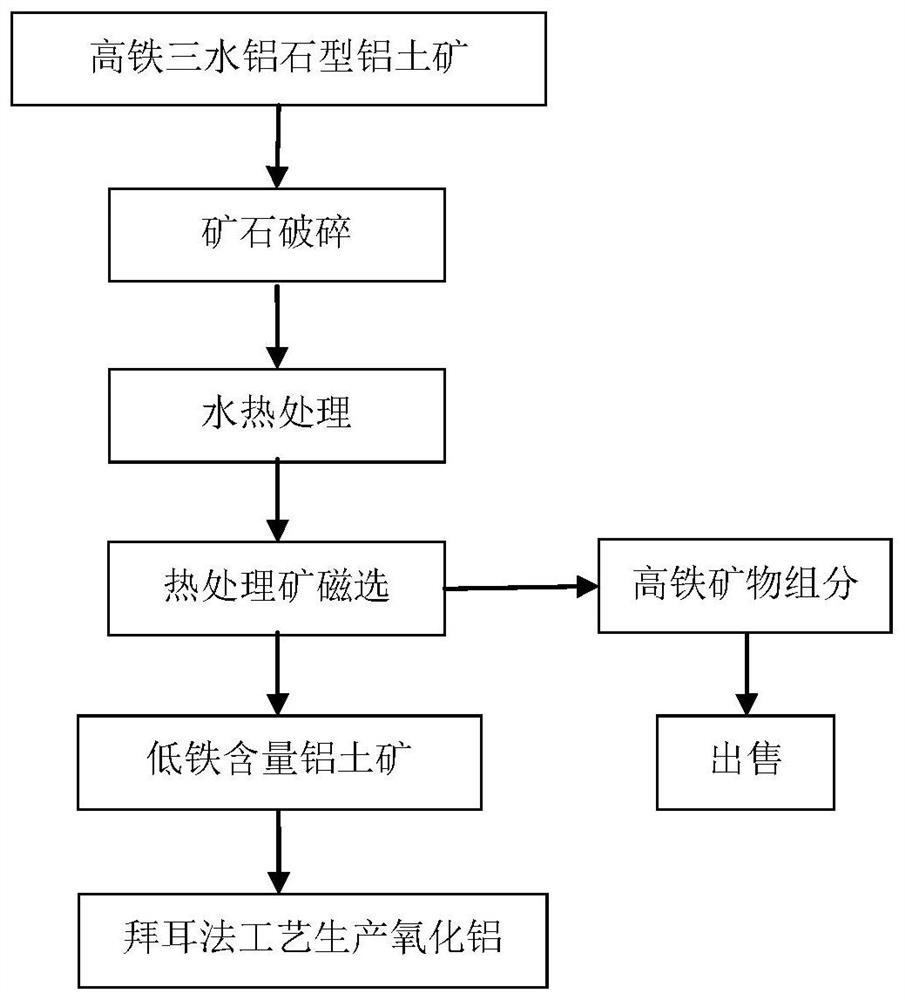

Iron removal method of high-iron gibbsite bauxite

A gibbsite type, bauxite technology, applied in chemical instruments and methods, aluminate/alumina/aluminum hydroxide purification, alkali metal aluminate/alumina/aluminum hydroxide preparation, etc. Solve the problems of general beneficiation effect, high equipment specification requirements, high environmental protection pressure, etc., to achieve better magnetic separation effect, strong selectivity, and reduce alkali consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The high iron gibbsite type bauxite raw ore is crushed and ground to obtain a ground ore, and the mass percentage of the ore particles on the sieve after the ground ore passes through a sieve with an aperture of 150 μm is 20%. The mass percentage of the undersized ore particles after 250 μm sieve is 99%. The ground ore and water are mixed into an ore slurry with a solid content of 300g / L, and the ore slurry is put into a pressure reactor for hydrothermal reaction. The reaction temperature is 250°C and the reaction time is 30min. After the reaction, a mixed slurry is obtained. After the reaction is completed, the material is discharged. Adjust the mixed slurry to a slurry with a solid content of 200g / L for magnetic separation. The magnetic field strength of the magnetic separation is 15000GS. After magnetic separation, a strong magnetic component solid with a high iron oxide content and a gibbsite type with a low iron oxide content are obtained Bauxite slurry; strong ma...

Embodiment 2

[0028] The raw ore of high-iron gibbsite bauxite is crushed and ground to obtain ground ore, and the mass percentage of ore particles on the sieve after the ground ore passes through a sieve with an aperture of 150 μm is 5%. The mass percentage of the undersized ore particles after 250 μm sieve is 100%. The ground ore and water are mixed into an ore slurry with a solid content of 50g / L, and the ore slurry is put into a pressure reactor for hydrothermal reaction. The reaction temperature is 200°C and the reaction time is 180min. After the reaction, a mixed slurry is obtained. After the reaction is completed, the material is discharged. Adjust the mixed slurry to a slurry with a solid content of 50g / L for magnetic separation. The magnetic field strength of the magnetic separation is 6000GS. After magnetic separation, a strong magnetic component solid with a high iron oxide content and a gibbsite type with a low iron oxide content are obtained Bauxite slurry; strong magnetic com...

Embodiment 3

[0030] The high iron gibbsite type bauxite raw ore is crushed and ground to obtain the ground ore. The mass percentage of the ore particles on the sieve after the ground ore passes through a sieve with an aperture of 150 μm is 10%. The mass percentage of the undersized ore particles sieved to 250 μm is 99.5%. The ground ore and water are mixed into an ore slurry with a solid content of 150g / L, and the ore slurry is put into a pressure reactor for hydrothermal reaction. The reaction temperature is 230°C and the reaction time is 60min. After the reaction, a mixed slurry is obtained. After the reaction is completed, the material is discharged. Adjust the mixed slurry to a slurry with a solid content of 100g / L for magnetic separation. The magnetic field strength of the magnetic separation is 9000GS. After magnetic separation, the strong magnetic component solid with high iron oxide content and the gibbsite type with low iron oxide content are obtained Bauxite slurry; strong magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com