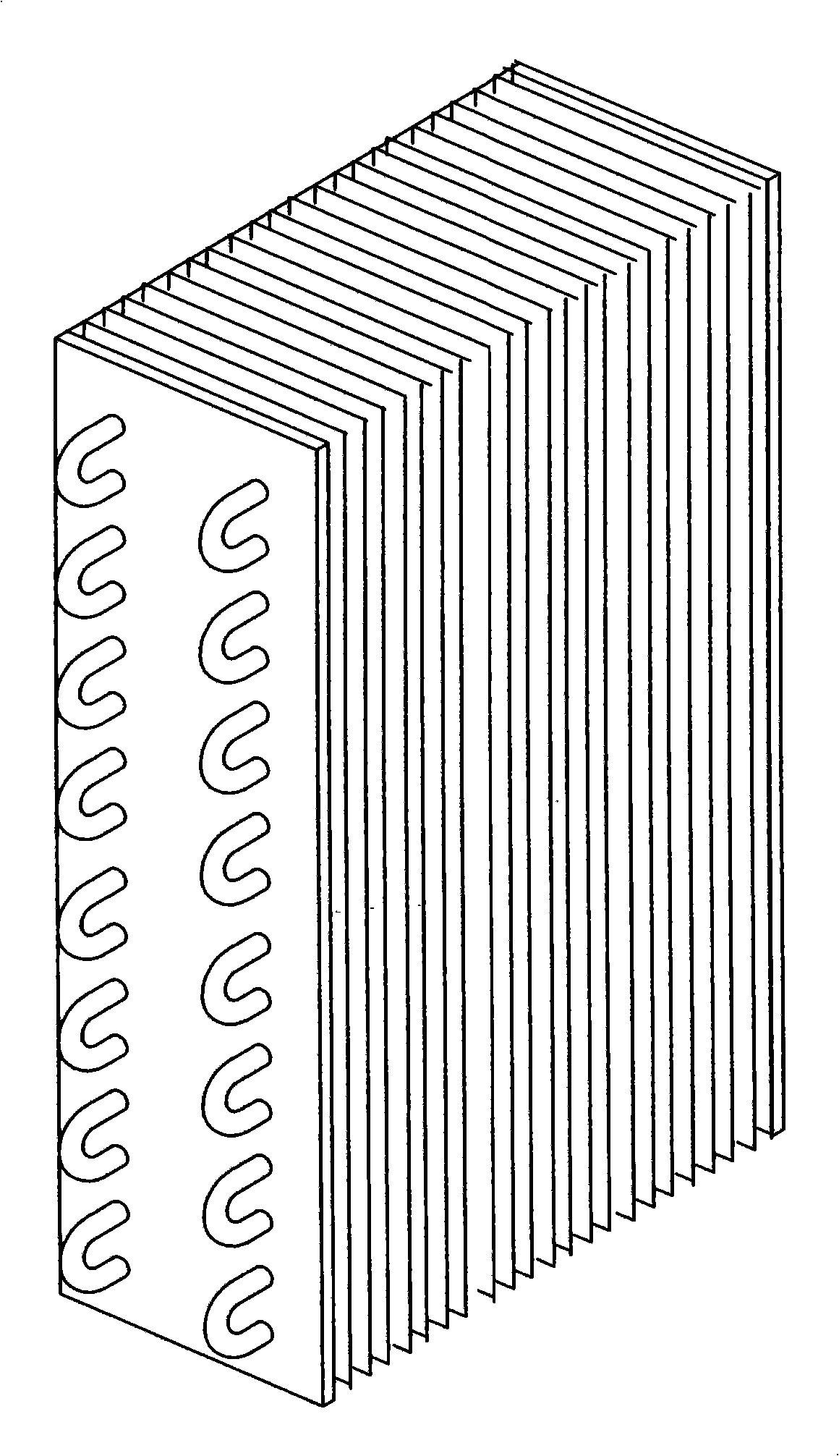

Finned tube type heat converter of air conditioner

A technology for tubular heat exchangers and air conditioning fins, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of low heat exchange performance, high heat exchange performance, and no competitiveness. Achieve the effect of low cost, high heat exchange efficiency and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Figure 5 , 6 It is a schematic diagram of the fin structure of Embodiment 1 of the fin-tube heat exchanger of the present invention. The fins described in this embodiment are corrugated fins, and the corrugated fins are V-shaped corrugated fins 11. The V-shaped corrugated fins 11 are flat fins pressed into a plurality of continuous V shapes, as shown in the figure. The embodiment pays attention to extruding four V shapes. Through the test, under the condition that the fin spacing d is 1.2 to 1.65 mm, the spacing A of the connecting holes is 21 mm, and the width C of each V-shaped corrugation is 9.09 mm. When the height h is 1.2 mm, the best heat exchange effect can be obtained without generating noise and increasing wind resistance. At this time, the width B of the fin can be increased to 36.36mm. Considering the V-shaped relationship, the actual width is 37.6mm. The reason why the increased width does not produce vibration noise is that pressing the V-shaped corrug...

Embodiment 2

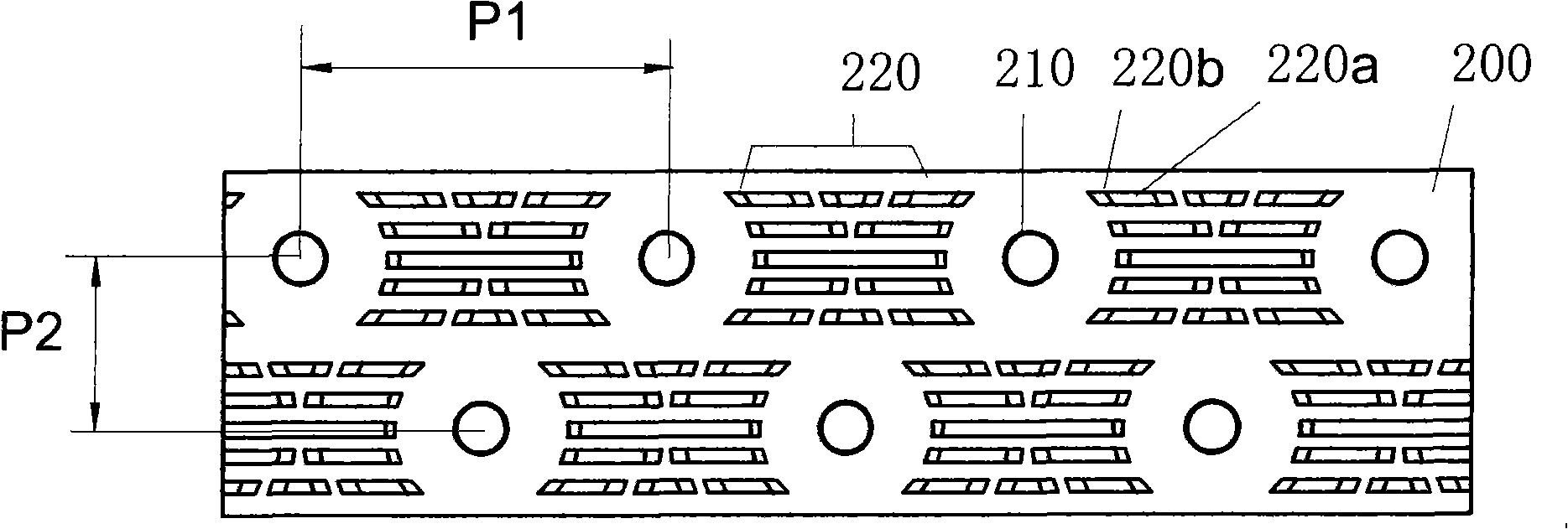

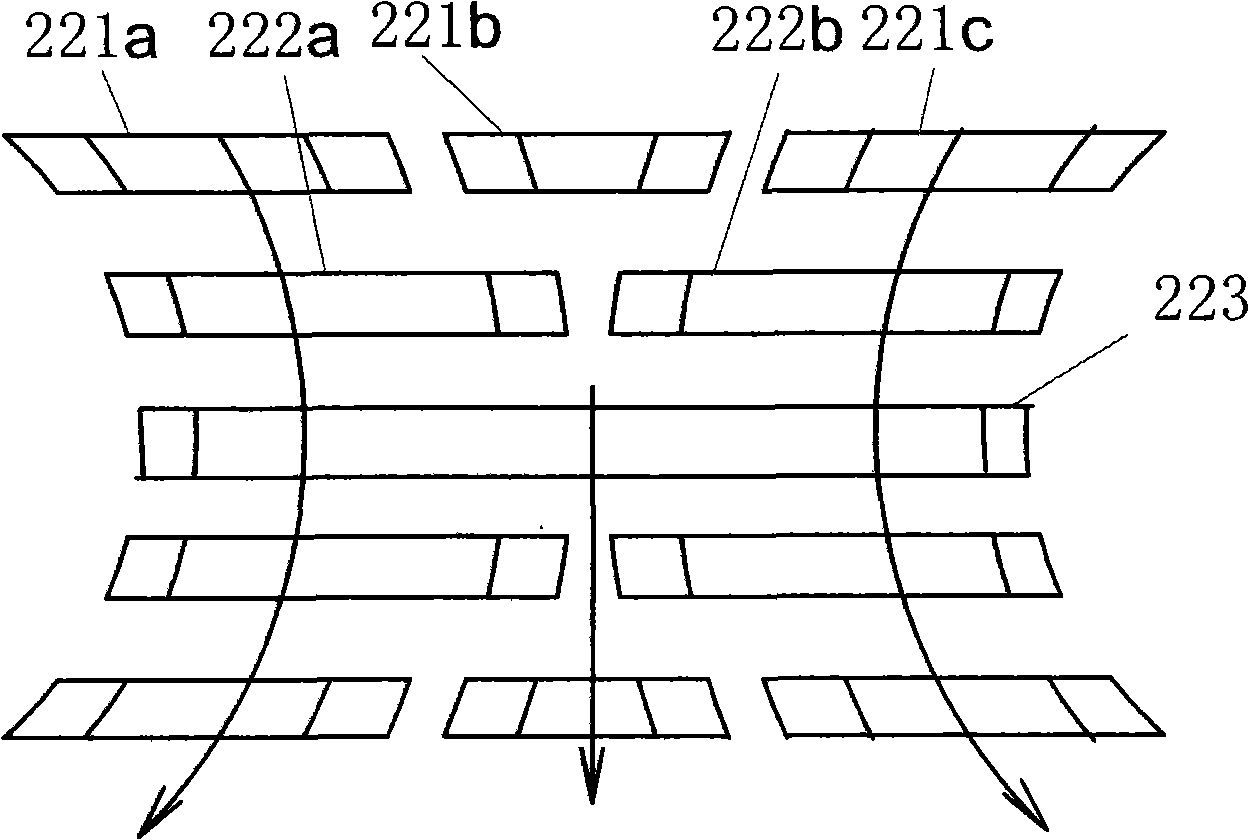

[0069] Figure 8 , 9 11 is a schematic diagram of the fin structure of Embodiment 2 of the fin-tube heat exchanger of the present invention. In the illustrated embodiment, the fins are slit fins 3, and the slit fins 3 are provided with a plurality of slits 30 in the spaces between the connection holes 10 of each row of the fins; The slit 30 is composed of a protruding section 31a and two upright sections 31b, and forms an opening facing the airflow direction between the fin plane, and the protruding sections of each slit protrude from the surface of each cooling fin in the same direction.

[0070] A plurality of slits between two adjacent connecting holes in each row of the slit fins form N rows, and each row has M slit units, and the center line of the two adjacent connecting holes and the vertical line of the line are X symmetrical arrangement. In the specific embodiment shown in the figure, the multiple slits between each row of connecting holes on the slit fin are arran...

Embodiment 3

[0075] Figure 13 It is a schematic diagram of the fin structure of Embodiment 3 of the present invention. In the illustrated embodiment, the fin is a slit fin 4, and the difference between the slit fin 4 and the slit fin 3 of Embodiment 2 is:

[0076] The plurality of slits between each row of connecting holes on the slit fin 4 are arranged in four rows in an X shape, wherein all four rows of slits are composed of one slit unit 411, 412; and the second and third rows The length of the slit unit is smaller than the length of the slit unit in the first and fourth rows, forming an X-shaped arrangement. in:

[0077] The projection of all the slit units in each row on the fin plane is an isosceles trapezoid; the projection on the plane perpendicular to the perpendicular bisector of the connecting hole center line is an isosceles trapezoid; The angle α between the perpendiculars of the lines connecting the holes is also 30°-38°, preferably 35°.

[0078] Figure 14 , 15 are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com