Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

A technology of active calcium silicate and coal gangue, which is applied in the directions of alumina/aluminum hydroxide, silicate, alkaline earth metal silicate, etc., can solve the problems of waste of resources, poor economy, cumbersome process, etc., and save production costs. , reduce energy consumption and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

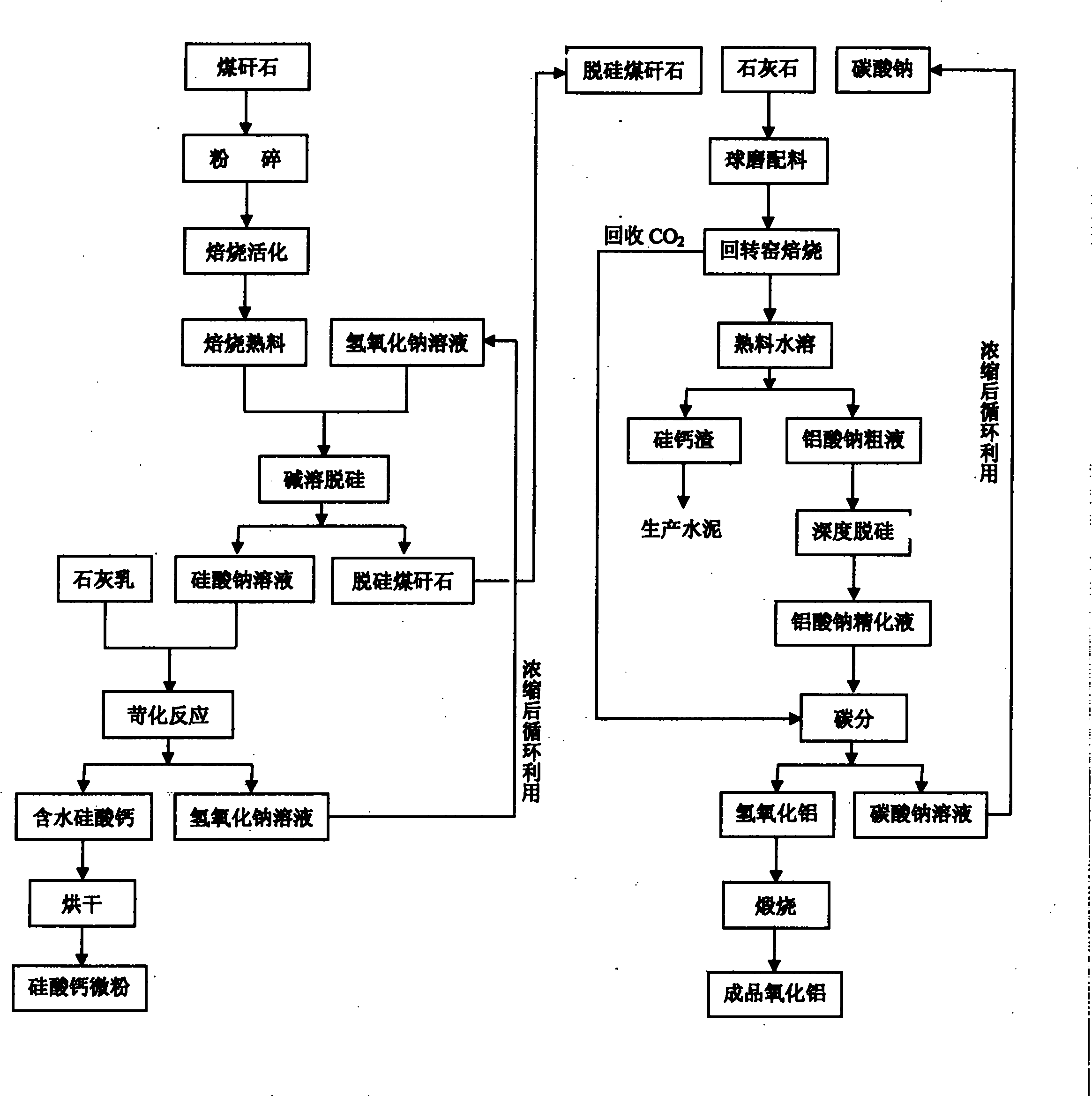

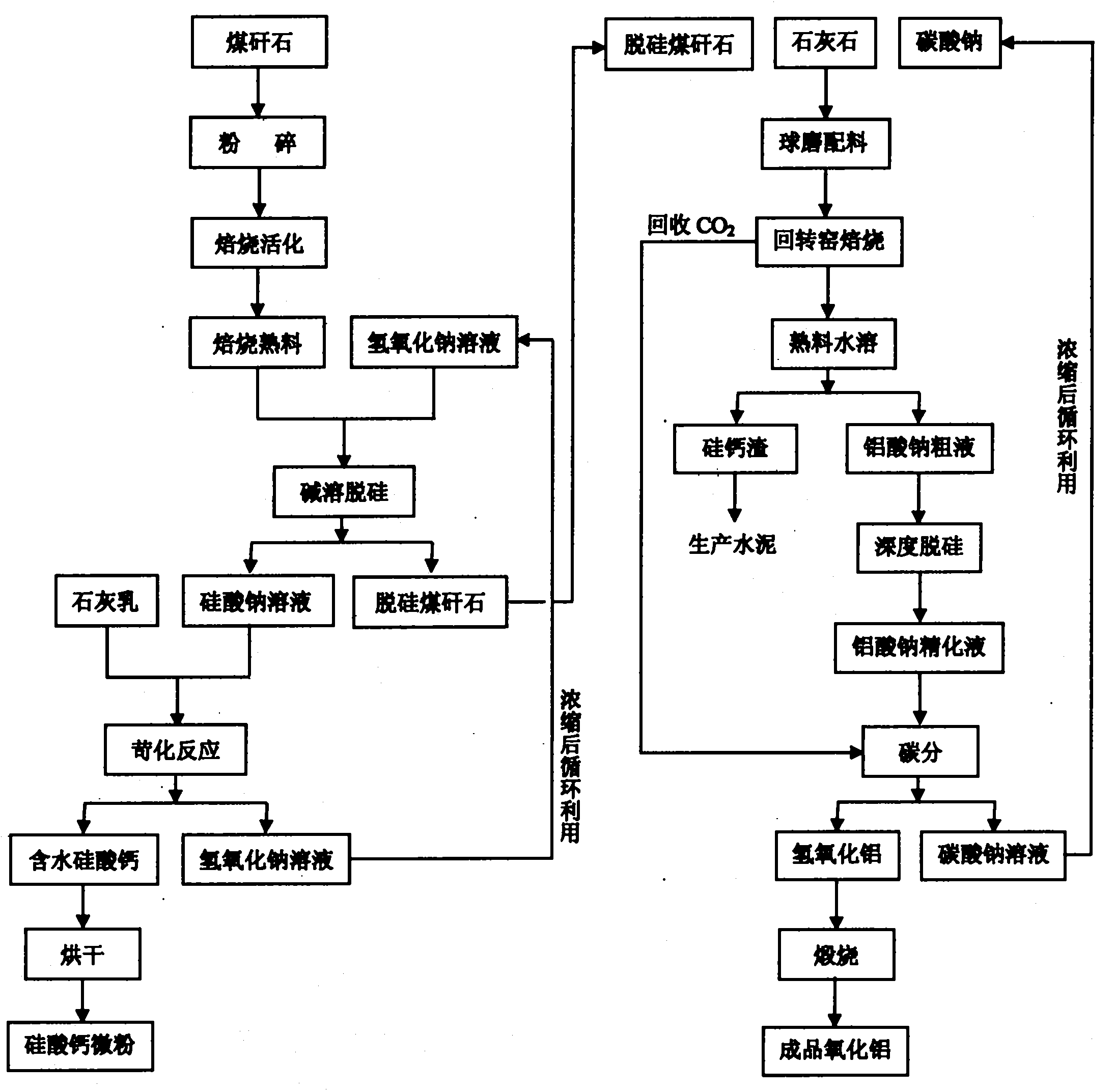

[0036] Referring to accompanying drawing, production step of the present invention is:

[0037] ① Raw material selection containing Al 2 o 3 42.93%, SiO 2 51.92% coal gangue, after being ground to 200 meshes, is activated by high-temperature roasting at a roasting temperature of 950°C and a holding time of 2 hours.

[0038] ② After the roasted clinker is naturally cooled, add 15% sodium hydroxide solution according to the mass ratio of coal gangue to NaOH of 1:0.5, and carry out desiliconization reaction at 110°C for 2 hours. After the reaction is finished, filter and separate to obtain the filtrate sodium silicate solution and filter cake desiliconized coal gangue.

[0039] ③ Add lime milk to the filtrate sodium silicate solution for causticization reaction, the amount of lime milk added is based on CaO and SiO 2 The molar ratio is 1.1, and the reaction temperature is 90°C. After reacting for 1 hour, filter and separate. The filtrate is sodium hydroxide solution, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com