Method for extracting lithium, rubidium and cesium in zinnwaldite

A technology for lithotripsy and an extraction method, applied in the field of metallurgy, can solve the problems of addition and low efficiency, and achieve the effects of simple purification process, low energy consumption, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

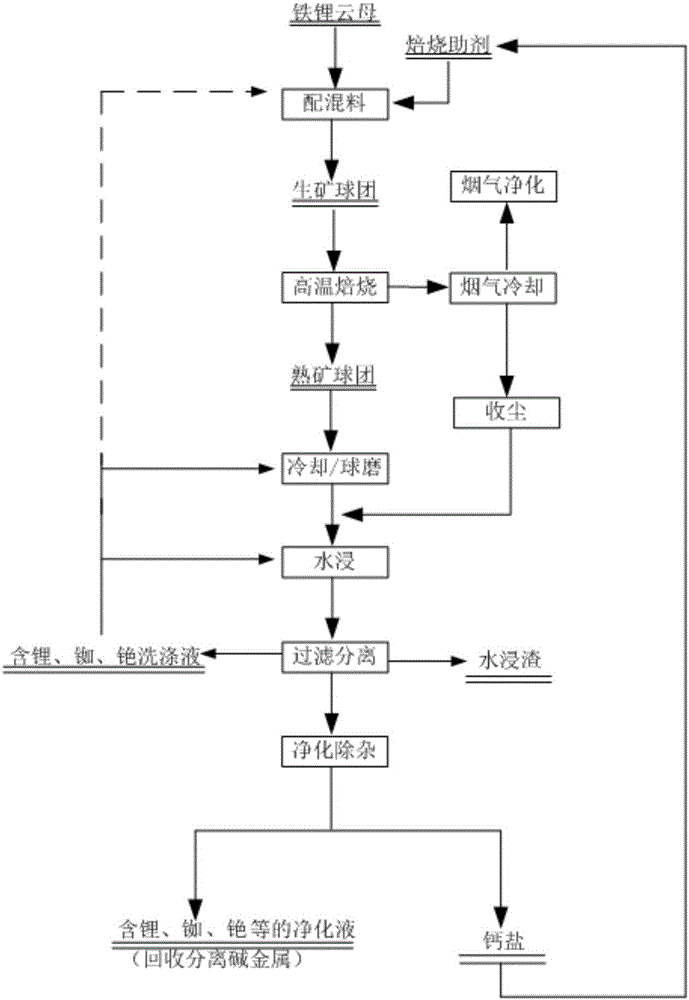

Method used

Image

Examples

Embodiment 1

[0036] The chemical composition and content of the iron lepidolite that the present embodiment adopts are: 2.40wt% Li 2 O, 0.34wt% Na 2 O, 8.34 wt% K 2 O, 0.86 wt% Rb 2 O, 0.073wt%Cs 2 O, 43.41wt% SiO 2 , 26.14wt% Al 2 o 3 , 18.86wt% FeO, 4.97wt% F.

[0037] Mix iron lepidolite, calcium sulfate, calcium hydroxide, sodium sulfate and calcium carbonate at a mass ratio of 1.00:0.4:0.17:0.3:0.2 to make raw ore pellets with a diameter of about 30mm; then the raw ore The pellets were roasted at 900°C for 60 minutes to obtain cooked ore pellets; the flue gas during the roasting process was cooled, collected and purified; the cooked ore pellets were quenched with water, wet ball milled, and then mixed with 90°C water at 3: Mix the liquid-solid mass ratio of 1, and stir for 40 minutes, and then filter to obtain the leaching solution containing alkali metal compounds such as lithium, potassium, rubidium and cesium; finally, add calcium oxide to the leaching solution to purify and...

Embodiment 2

[0045] The chemical composition and content of the iron lepidolite that the present embodiment adopts are: 2.13wt% Li 2 O, 0.34wt% Na 2 O, 9.34 wt% K 2 O, 0.63 wt% Rb 2 O, 0.043wt%Cs 2 O, 48.41wt% SiO 2 , 27.14wt%Al 2 o 3 , 21.86wt% FeO, 5.77wt% F.

[0046] Mix iron lepidolite, calcium sulfate, calcium hydroxide, potassium sulfate and calcium carbonate at a mass ratio of 1.00:0.4:0.2:0.2:0.3 to make raw ore pellets with a diameter of about 25mm; then the raw ore The pellets were roasted at 900°C for 50 minutes to obtain cooked ore pellets; the flue gas during the roasting process was cooled, collected and purified; the cooked ore pellets were quenched with water, wet ball milled, and then mixed with 40°C water at 4: Mix the liquid-solid mass ratio of 1, and stir for 30 minutes, and then filter to obtain the leaching solution containing alkali metal compounds such as lithium, potassium, rubidium and cesium; finally, add calcium oxide to the leaching solution to purify an...

Embodiment 3

[0053] The chemical composition and content of the iron lepidolite that the present embodiment adopts are: 2.69wt% Li 2 O, 0.34wt% Na 2 O, 8.12 wt% K 2 O, 0.93 wt% Rb 2 O, 0.086wt%Cs 2 O, 41.41wt% SiO 2 , 30.14wt%Al 2 o 3 , 20.67wt% FeO, 5.09wt% F.

[0054] Mix the iron lepidolite ore, the purification slag in Example 1, calcium sulfate, potassium sulfate, calcium hydroxide and calcium carbonate at a mass ratio of 1.0:0.1:0.4:0.2:0.25:0.3, and make a diameter of about 20mm Raw ore pellets; then roast the raw ore pellets at 950°C for 60 minutes to obtain cooked ore pellets; and the flue gas during the roasting process will be cooled, collected and purified; the cooked ore pellets are quenched with water, and wet Ball milling, and then mixed with 50°C water at a liquid-solid mass ratio of 2:1, stirred for 40 minutes, and then filtered to obtain a leaching solution containing alkali metal compounds such as lithium, potassium, rubidium and cesium; finally, calcium oxide was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com