Method for comprehensively recovering iron and germanium from zinc calcine containing high iron and high indium

A technology of zinc calcine and iron recovery, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of unrecyclable tailings, complicated operation process, high cost, etc., and achieve easy operation, short process flow and low emission The effect of less pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

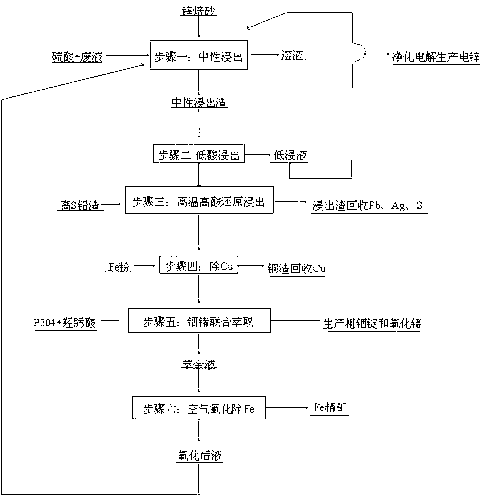

Image

Examples

Embodiment 1

[0045] 1. Add 23m3 of waste electrolyte containing 145g / L of sulfuric acid and 48g / L of zinc into the reactor, and then put in zinc containing 12.8% Fe, 0.086% In, 0.019% Ge and 54.5% zinc 3000kg of calcined sand is subjected to neutral leaching, the temperature is 68°C, the leaching time is 2 hours, and the pH of the leaching end point is 5.2; 20m3 neutral leaching solution containing 142g / L zinc is produced, and zinc powder is added for purification to produce electrolytic zinc by electrolysis. 1783 kg of neutral leaching residue with a moisture content of 15% was produced.

[0046] 2. Leach 1,783kg of the neutral leaching residue with a sulfuric acid solution containing 55g / L of acid at a liquid-solid ratio of 3 / 1, at a temperature of 60°C, for 2 hours of leaching time, at the end of leaching pH=4.8, and produce zinc-containing 5.3m3 of 65g / L low-acid leach solution and 1458kg of low-acid leach residue with 15% moisture content.

[0047] 3. Add 1458kg of the lo...

Embodiment 2

[0052] 1. Add 23m3 of waste electrolyte containing 145g / L of sulfuric acid and 48g / L of zinc into the reaction tank, and then put in zinc containing 18.4% Fe, 0.152% In, 0.025% Ge and 56.7% zinc 3000kg of calcined sand is subjected to neutral leaching, the temperature is 70°C, the leaching time is 2 hours, and the pH of the leaching end point is 5.2; 20m3 neutral leaching solution containing 136g / L of zinc is produced, and the neutral leaching solution is added with zinc powder for purification and electrolysis to produce electricity Zinc, while producing 1756kg of neutral leaching slag with a moisture content of 18%.

[0053] 2. Leach 1,756kg of the neutral leaching residue with a sulfuric acid solution containing 60g / L of acid at a liquid-solid ratio of 3 / 1, at a temperature of 60°C, for 2 hours of leaching time, at the end of leaching pH=4.8, and produce zinc-containing 4.8m3 of 68g / L low-acid leaching solution and 1667kg of low-acid leaching residue with a moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com