Cation type polymer flocculating agent and its preparation method

A polymer flocculant and cationic technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor flocculation bridging ability and low molecular weight of flocculants, and achieve less slag, good flocculation effect and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

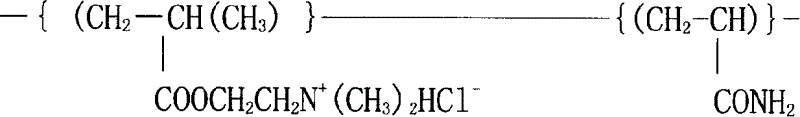

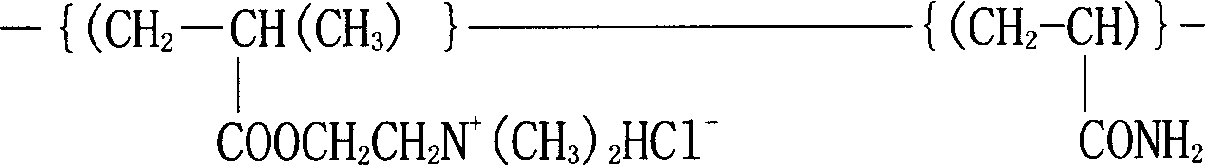

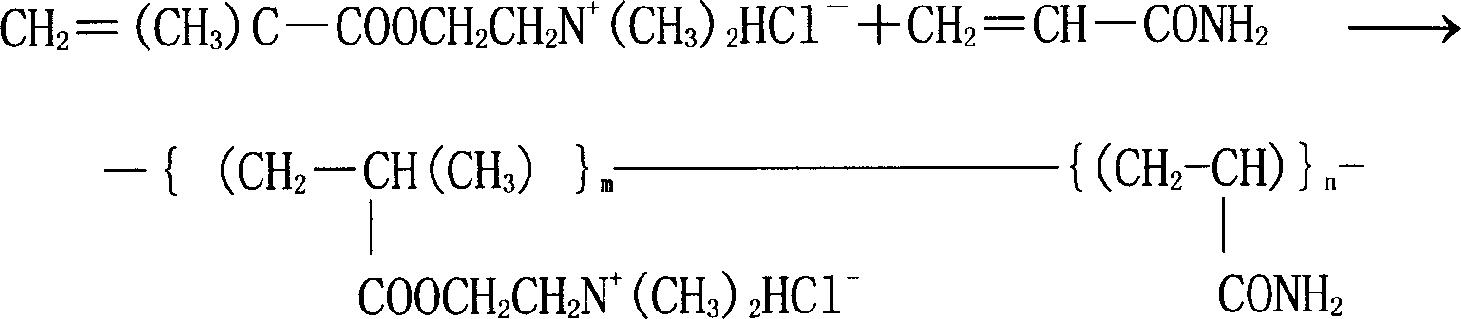

Method used

Image

Examples

Embodiment 1

[0018] In a 500ml four-neck flask equipped with a stirrer, a thermometer, a feeding tube, and a nitrogen inlet and outlet, add 15.7g of dimethylaminoethyl methacrylate, add 15ml of 1N HCl, adjust the pH value to 5.5, and then add acrylamide 28.4 g, 400ml of deionized water, after mixing evenly, blow nitrogen to remove oxygen, add initiator potassium persulfate 10-4mol / L, react in 50°C water bath for 6 hours, and obtain flocculant-1.

Embodiment 2

[0020] In a 500ml four-neck flask equipped with a stirrer, a thermometer, a feeding tube, and a nitrogen inlet and outlet, add 37.68g of dimethylaminoethyl methacrylate, add 45ml of 1N HCl, adjust the pH value to 4.0, and then add acrylamide 4.26 g, 440ml of deionized water, after mixing evenly, pass nitrogen to remove oxygen, add initiator ammonium persulfate 5×10 -4 mol / L, initiator sodium sulfite 2×10 -5 mol / L, react in a 35°C water bath for 3 hours, and then react in a 80°C water bath for 2 hours to obtain Flocculant-2.

Embodiment 3

[0022] In a 500ml four-neck flask equipped with a stirrer, a thermometer, a feeding tube, and a nitrogen inlet and outlet, add 28.8g of dimethylaminoethyl methacrylate, add 30ml of 1N HCl, adjust the pH value to 7.0, and then add acrylamide 16.9 g, 400ml of deionized water, after mixing evenly, pass nitrogen to remove oxygen, add initiator ammonium persulfate 4×10 -4 mol / L, in a 45°C water bath, react for 5.5 hours to obtain flocculant-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com